![]()

Ⅴ Pipeline and Expansion Valve Assy.

Ⅺ Rear Row Face Mode Air Duct Assy

1 BCM Remote Key Code Learning Guide

1Disassmebly

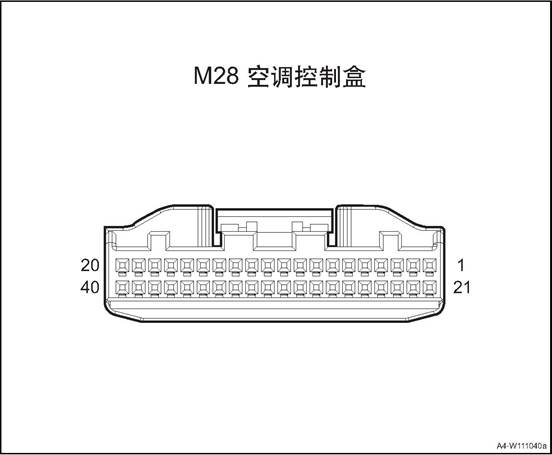

Ⅻ A/C Control Box Assy. (Electric)

XVII Inner& Outer Circulation Throttle Motor

![]()

![]()

Definitions of "warning", "important note" and "attention"

The diagnostic and maintenance procedures in this manual include general and specific "warnings", "important notices" and "cautions", and JAC is committed to providing maintenance information to assist the after-sales service technician in the diagnosis and maintenance system , so that the vehicle can run normally, but if the technician does not operate as recommended, some programs may pose a risk to the technician.

"WARNING", "IMPORTANT NOTE" and "CAUTION" are prepared to prevent the occurrence of such hazards, but not all hazards are predictable. This information is displayed in prominent positions in the maintenance manual. This information is prepared to prevent the following:

·Causing serious injury to people

·Vehicle damage

·Unnecessary vehicle maintenance

·Unnecessary parts replacement

Improper repair or replacement of vehicle parts

The definition of "warning"

When you encounter a "warning", it asks you to take the necessary action or to prohibit the action taken. If you ignore "warning", you may have the following consequences:

·Causing serious injury to people

If the vehicle is improperly repaired, it will cause serious personal injury to the driver and / or passenger of the vehicle.

The definition of "Important Note”

"Important note" requires special attention to the measures necessary or prohibited. If you ignore the "IMPORTANT NOTE", it will lead to the following consequences:

·Vehicle damage

·Unnecessary vehicle maintenance

·Unnecessary parts replacement

·Abnormal operation or performance of the system or component being repaired

·Damage related systems or components

·Damage fasteners, basic tools or special tools

·Engine coolant, lubricating oil or other essential liquid leakage

The definition of "Attention”

The "CAUTION statement emphasizes the necessity of a diagnostic or maintenance procedure, and the purpose of the "attention" statement is as follows:

Clear procedure

Provide supplementary information for completing a program

Clarify the reason for an operation according to the recommended procedure

Provide information that helps to complete the program in a more efficient way

Provide the technician with past experience information to make the process easier

△Warning To avoid vehicle damage, serious personal injury or even death, when the main part is removed from the vehicle and the vehicle is supported by an elevator, please use jack to support the corresponding vehicle parts to be dismantled.

△ Warning To avoid personal injury when exposed to toxic flamings generated from wipes or electroplating (zinc oxide) metal during grinding / cutting of any type of metal or sheet molding, the working process must be operated in a well-ventilated area and technician should equip permitted respirators, goggles, earplugs, welders gloves and protective clothing.

△ Warning When the technician checks the defective parts, the vehicle should be driven by the assistant. Otherwise, it may cause personal injury.

△ WARNING Before servicing any electrical parts, the ignition key must be in the OFF or LOCK position and all electrical loads must be "OFF"

), Unless otherwise stated in the operating procedure. If the tool or equipment is easily accessible to the exposed live electrical terminals, disconnect the battery negative cable. Violation of these safety instructions may result in personal injury and / or damage to vehicles, vehicle parts.

△ Warning If you repair the airbag, you must disconnect the battery negative at least 90s in order to carry out other operations.

△Warning Please Avoid absorbing A/C refrigerant ,134a(R134a),Lubricating oil steam or fog otherwise it will stimulate the eyes, nose, and pharynx. Operation shall be performed at place with good ventilation

/ When exhausting R134a from A/C system, please use service facilities that meet the standard of SAEJ2210

(R134a recycling facilities) If unexpected fluid leak happens, please ventilate workplace before continuing repair. /

For other information concerning health and safety, please consult manufacturer of refrigerant and lubricating oil for details.

△ Warning please cut the recommended parts only, otherwise it will damage the integrity of the vehicle structure, and may cause personal injury in the event of vehicle collision.

△ Warning If crack appears on the window, yet the window is intact, please use protective glue tape and stamp the tape on the window in crossing type, so as to avoid further damage or personal injury.

△Warning When the driver handle the power window, the function of lifting the window fast may Cause personal injury

△Warning In the course of this procedure, licensed goggles and gloves should be worn to reduce the risk of personal injury.

△ Warning If fire is needed during repair process, the noise-insulating foam material with a distance of 152.4mm within the fire must be cleared. When re-installing foam material, please avoid inhaling smog, or your health will be affected.

△ Warning In the course of processing glass or metal sheet with sharp or rough edge, licensed goggles and gloves should be equipped to reduce the risk of personal injury.

△ Warning high-pressure gas exist inside the bulb. Improper operation may cause bulb’s explosion. To avoid personal injury:

Turn off light switch and cool down the bulb before replacing bulb

Keep the light switch shut down until the bulb has been replaced

Please equip goggles while replacing halogen bulb

While handling bulb, please hold the base part only and avoid contact with glass

The bulb should be kept away from dust and moisture

Please scrap the aged bulb in correct procedures

The halogen bulb should be kept away from children

△ WARNING When working around the running engine, avoid contact with moving parts and hot surfaces to prevent personal injury.

△ WARNING Do not wear goggles and gloves when removing exhaust system parts, otherwise rusting and sharp edges from worn parts of the exhaust system can cause serious personal injury.

△ WARNING To avoid being burned, do not remove the tank cover until the engine is cooled. If the tank and the radiator are not cooled, remove the tank cover, the cooling system will release hot high pressure liquid and steam.

△WARNING Please test vehicle with your safety guaranteed and follow traffic regulations. Do not attempt any operation that may endanger vehicle control. Violation of these safety instructions may result in serious personal injury and vehicle damage.

△Warning When processing fuel, be sure to equip goggles to prevent oil from splashing into the eyes.

△ Warning Airbag system has been equipped on this vehicle. Failure to carry out correct operation procedures may cause following situations:

Unexpected airbag explosion

Pre-tightener spark-off

Person injury

Unnecessary repair of airbag system

△ Warning please obey the following instructions to avoid the situations mentioned above:

Please refer to the overview of airbag system, and confirm whether repairing operations are carried out on airbag system’s parts and circuits.

Please secure the airbag system if you are carrying out repair on airbag system’s parts and circuits.

△ Warning when the airbag is released, the metal surface of airbag system module will be very hot. To avoid fire accident and personal injury:

Make sure the metal surface is fully cooled down for a certain time before touching

Do not put the released airbag system module near any inflammable objects.

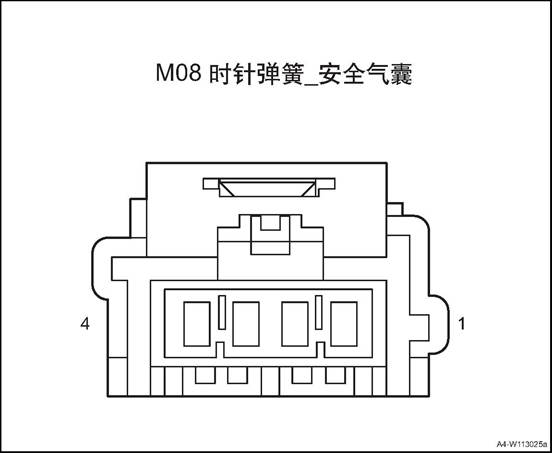

△ Warning incorrect assembly of clock spring may cause damage to the inner spiral coil, which will cause failure of coil and airbag module, and lead to potential personal injury.

△ Warning to avoid unexpected release of airbag and personal injury, do not operate the unreleased airbag module as scrapped objects in workplace.

If the sealing container is damaged during scrapping process, some materials in the unreleased module may cause illness or personal injury. /

Please discard the unreleased airbag module by following releasing procedures.

△ Warning while transporting unreleased airbag module:

Do not lift the wire or connector on airbag module

Ensure the airbag’s opening hasn't been put toward you or other people.

△ Warning while storing unreleased airbag module, ensure the airbag's opening is not facing the surface of airbag itself. The opening cannot be faced down, and no object should be put on airbag module. Enough space should be provided for airbag’s unexpected release so as to avoid personal injury.

Do not soak the unreleased airbag module into water or other fluids. Do not place the unreleased airbag module near fire or high-temperature area in case of personal injury caused by airbag’s unexpected release.

△ Warning Do not shake or knock the collision sensor of airbag system. Before charging collision sensor, make sure the sensor has been fixed tightly.failure to obey correct assembly procedures may cause unexpected release of airbag and personal injury.

△ Important notes: do not fix the lifting jack under oil sump, stamping parts or crankshaft belt pulley under any circumstance.

Improper lifting may cause damage to vehicle parts.

△ Important Note: while removing logo / nameplate, please use plastic tool with flat edge to avoid damage on paintwork

△ Important Note: Please use the correct fastener in the correct position. Replace the part number of the fastener must be correct, need to replace the fastener or need to use

Thread locking glue or sealant fasteners are specified in the maintenance procedure, and no paint, lubricating oil or corrosion inhibitor may be used on the fastener or fastener connection surface unless otherwise stated.

These coatings affect the torque and clamping forces of the fasteners and damage the fasteners. When assembling fasteners, be sure to use the correct fastening sequence and tightening torque to avoid damage to parts and systems.

△ Important Note: electrostatic discharge (ESD) will cause damage to solid electric component. Not all components that subject to ESD have been marked with ESD symbol. Therefore, please handle electric components carefully. Please obey the following safety instructions to avoid damage caused by ESD:

-Before repairing electronic component, touch the metallic bonding point and release the static inside body (especially after sliding vehicle seat)

-Do not touch the exposed terminal. The terminal may be connected to circuit which may be damaged by static.

-When repairing connector, do not make tools contact the exposed terminal.

-Do not dismantle parts from protective cap unless otherwise stated.

Avoid following operations unless otherwise stated by diagnostic program:

-Bridging or bonding of components or connectors

-When connecting testing facility’s probes to all parts or connectors, connect binding wire first before using test probes Before opening protective cap of component, please bind the component first. Do not put the solid component on metallic worktable, television, radio or other electric devices.

△ Important note: when connecting/disconnecting battery cable, charger or jumper cable, make sure the ignition switch is at “OFF”. Otherwise the control module or other electric components may be damaged.

△ IMPORTANT NOTE: The inlet and outlet hoses may not be twisted during Installation and may not bend or deform the hose for ease of Installation, as this may cause parts damage.

Parts are damaged.

△ Important note: before diagnosing vehicle, please pay attention to following situations or the control module may be damaged.

-Make sure the software version of tester and terminal are latest

-The vehicle battery must be fully charged and the battery’s voltage should be between 12-14V

The connection of tester and terminal cable should be tight

While programming control module, the charger shouldn’t be connected to battery

△ Important note: the lasting time for steering wheel at its limit position shouldn't exceed 5 seconds, otherwise the steering pump may be damaged.

△ Important Note: do not insert the probe of testing facility (digital multimeter and etc.) into wire connector or the terminal of fuse box. The diameter of testing probe will deform most terminals. Deformed terminals have poor contact, which may cause system failure. Make sure to apply special tool and test terminal from front side. Do not use clip or other substitutes to test the terminal.

△ Important Note: while using special tool to test components, make sure the testing adapter can match to the dimension of terminal. Do not choose adapter by eyeballing, as some terminal’s hole may be bigger than that of actual terminal.

Choose a terminal test adapter, as some connector terminals may appear to have larger holes than the actual terminals in the hole. Using a large terminal test adapter can damage the terminals

△ Important note: to avoid damage on vehicle windows caused by exposed edge, the window must be 1mm lower than the surface of metal sheet to avoid the damage.

1 Items should be checked when operating vehicle

Please press the honk occasionally to ensure the honk is working well. Check all buttons.

While braking, please check whether abnormal noise/sound, increase of brake pedal’s stroke or repetitive lane departure exists. Furthermore, if the brake warning light keeps lighting or flickering, some failures may exist inside brake system.

2 Items should be checked when fuel-charging

Oil/fluid loss of all systems except for windshield washer means the system has failure. Please check and repair system immediately.

Check the liquid level of cleaning agent in liquid reservoir, and add cleaning agent if necessary.

Check the operation of license lamp, headlamp (low/high beam), parking lamp, fog lamp, tail lamp, brake lamp, steering lamp, reversing lamp and hazard warning lamp.

After the vehicle has been parked for a period of time, please check regularly whether water, engine oil, fuel or other fluid exist under the vehicle. Water-dripping is a normal phenomenon when the air conditioning system is used . if fuel leak or smoking is detected, please check reasons and eliminate fault timely.

Apply a layer of silicone grease to the seal with a clean cloth.

Check safety belt system, including the strap, buckle, lock plate, retractor, guide ring and fixing device.

Beware of the crunching sound appeared in vehicle’s rear part. Spare tire, lifting device and tools must be fixed all the times. Please use engine oil to lubricate the ratchet or spiral device of lifting jack after use.

Lubricate key cylinder

Lubricate all hinges on vehicle doors, engine cover, oil filler cap, tail door, plunger latch, glove box and control console. All components of folded seats need to be lubricated.

First, loosen the deposit sediment gathered around vehicle’s sealed area. Then use clean water to rinse vehicle’s bottom. After winter, the vehicle’s bottom should be cleaned once a year at least. Rinsing vehicle’s bottom can remove the corrosive material that can be used for deicing or dust-proof.

Please refer to "Warnings about vehicle lift" in the "Warnings and Precautions".

To avoid personal injury, be sure to use the jack when you are working on a vehicle that is only jack-mounted or under a vehicle. Put the cushion block of rear lifter beneath the junction between the rear frame rail and side frame rail.

△ Attention that the rear lift block can not hit the sill plate to the outside of the frame rails or the floor.

Put the cushion block of front lifter beneath the junction between the rear frame rail and side frame rail.

△ Attention that the rear lift block can not hit the sill plate to the outside of the frame rails or the floor.

|

Application |

Specification |

|

Refrigerant |

480±20g |

Recommended oil/liquid and lubricating oil

|

application |

Oil&liquid / lubricating oil |

|

A/C refrigerant |

R134a |

|

Windshield cleaning agent |

NC310-c |

|

Hinge of engine cover, vehicle door, oil filler cap and tail door |

General lithium-based grease for vehicle |

|

sealing strip for doors and windows |

Silica-based lubricating grease |

2 Regular Maintenance Instructions

The maintenance items given in the maintenance plan has assumed that the vehicle is used for the following purposes:

Passengers and cargo are transported under the constraints indicated by the tire label at the driver's door edge.

Drive on the proper road surface and within the legal limits.

Maintenance items listed in the maintenance items detailed below, in the implementation of the following maintenance items, be sure to replace all parts and make all necessary repairs before they can drive on the road, be sure to use the appropriate fluids and lubricants.

Ⅴ Maintenance Information System

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

1 Arrows and

symbolic description used in the manual

1 Arrows and

symbolic description used in the manual

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() 1 Indicator arrows

1 Indicator arrows

2 Move direction arrow

3 Rotation direction arrow

4 Part number label

5 Partial magnification

Many of the operations related to vehicle maintenance and repair can affect your safety or health issues. Some hazardous operations, materials and equipments and safety rules to avoid hazards have been listed in this session.

This section does not cover all matters related to health and safety, so all operations and procedures and materials should be handled on the premise of safety and health. Before using any product, please check the product manual provided by the manufacturer or supplier.

For example, corrosive sodium carbonate, sulfuric acid.

Used for battery and other materials’ cleaning.

Irritation or erosion for the eyes, skin, smell and throat, and will cause burns to the human body and damage to ordinary protective clothing.

Avoid splashing on eyes, skin and clothing. Wear proper protective clothing, gloves and goggles to prevent inhalation.

Be sure to include flushing equipment nearby, such as eye wash bottles, shower pads, soap, etc., for immediate relief in the event of splashes.

Marked signs of eye danger in a prominent position.

For highly inflammable or explosive materials—please follow no-smoking rules

Air bags are assembled as auxiliary safety system in steering wheel, seats of front passengers, front dashboards and A column, B column and C column.

A high-energy propellant that can generate extremely high-temperature (2500℃ /4532 ℉) gas has been equipped in the air bag expander.

This propellant is sealed in closed components, and will filled into airbag after reacting with airbag. During repair process, do not open airbag, because this will make propellant contact airbag and cause hazard. If air-generator is found broken, please equip full-protective clothing when processing spilled material.

When airbag has been set off normally, please equip safety goggles and gloves during processing. The released air bag should be processed according to relevant laws and regulations in local area. If you have direct contact with ramification of air, please:

Wash contacted part with water

Seek medial assistance if necessary

For your safety, please wear protective equipments before carrying out following operations; when dismantling airbag, make sure the vehicle’s ignition switch is at “LOCK”. Pull up the key and disconnect negative cable, then proceed disassembly process after 90 seconds.

Store the airbag components in straight position

When storing, keep the airbag dry.

When moving airbag components, do not touch electrode and keep airbag away from body.

Place airbag component with protecting cover facing up.

Check whether airbag component is damaged

Disconnect battery’s cathode cable when connecting airbag, and stand in the side of airbag component after waiting 60 seconds.

Rectify and maintain all devices accurately.

Wash hands after processing the released airbag.

Airbag — operations should be avoided

Do not store inflammable material or component together with gas-generator.

Do not soak the unreleased airbag module into water or other fluids.

Do not store gas-generator in area which has a temperature higher than 80 ℃ /176 ℉

Do not store components upside down.

Do not try to open the cover of gas-generator

Do not expose gas-generator to fire or heat source Do not place other object on components’ protective cover

Do not use damaged component

Do not touch the component or gas-generator within 10 minutes after the airbag component is set off Do not use electric probe on the circuit.

Physical contact may lead to frostbite. Please follow the instructions provided by manufacturer. Do not make refrigerant exposed to light, and wear proper goggles and gloves.

If your skin or eyes has contact with refrigerant, use water to rinse the contacted area immediately. Use proper rinsing solution to clean your eyes. Do not rub your eyes and seek medical assistance according to actual situations.

A/C refrigerant — operations should be avoided

Do not store refrigerant in places that are exposed to sun or have heat sources nearby.

When filling refrigerant, do not keep refrigerant bottle straight. Keep the bottle’s valve facing down.

Do not expose refrigerant bottle exposed to frost or snow.

Do not drop refrigerant bottle. Do not release refrigerant into air under any circumstance. Do not blend refrigerant, like mixing R12 (dichlorodifluoromethane) and R134a (tetrafluoroethane)

Before applying binder and sealant, make sure the applied surface should be clean. Please use specified cleaning agent to scrub the applied surface so as to guarantee the binding effect. while applying sealant, do not let the glue solution enter into thread's blind hole, as the glue solution will generate hydraulic locking effect when the fastener is fastening, which will lead to damage on fasteners and/or other components. Furthermore, the glue solution will make fastener unable to acquire correct clamping force during fastening, and deteriorate the sealant's performance. This will cause fasteners unable to fasten correctly, loosen or separate components and cause severe damage to engine or other components.

Hazardous materials exist in binder and sealant, and long-time contact with these material will cause acute/slow disease, occupational disease, skin disease and etc. While gluing, please use venting device to keep the ventilation in workshop; during operation, please wear protective gloves, goggles and clothings. After the process, please wash hands and keep the cleanness and tidiness of workshop.

the waste of wasted glue or solvent’s pollution should be cleaned timely. Long-time accumulation is prohibited. Products should be stored in non-smoking area and keep cleanness while using. Please use applying device or container to proceed working process as far as possible.

When failure or accident happens on vehicle, it may cause vehicle’s deformation, steel plate’s cracking and welding spot’s fall-off. It may cause partial damage to engine, chassis or other assemblies and make binder/sealant’s fall-off and damage. During the repair process, please choose proper binders according to the component’s texture and functions. Some binder/sealants that may be used during repair process have been listed follow for your reference during repair process.

When the interior trim and steel plate of vehicle body are deformed or cracked, the binder will fall off or be broken. Therefore the parts that applied with binder should be fixed during repair process.

Please use knife to clean the binder on vehicle body’s surface, and use alcohol to scrub the remnant binder; please use specific cleaning agent to scrub the glued parts to avoid the existence of remnant glue or other foreign material on applying surface; then apply fixing binder on the original gluing part to glue and seal components.

Some parts (inner trim component, engine, gearbox and etc.) needs to be glued or sealed if suffering damage. While applying sealant, please clean the binding surface so as to avoid the negative effect of rag and crack.

The binder/sealant can prevent water and dust from entering into vehicle, and is corrosion-resistant The original sealing joints are apparent. If these joints are broken, they need to be re-sealed. Please use binder/sealant with high-viscosity while sealing the openings and joints. Please follow the instructions of the chosen materials

-While applying binder/sealant, precautionary measures must be taken to prevent binder/sealant from entering into components’ opening (door lock, glass-lifting groove, glass regulator and safety belt’s retractor) or other moving, rotary components, especially parking brake’s drawing. After applying binder/sealant, make sure all release holes of vehicle are open.

-When processing, please wear specific protective goggles and gloves to prevent personal injury.

-When vehicle leaves factory and all metal sheets of vehicle have been coated, repaired and replaced with new spare parts, please apply rust-proof base coat on the surface of exposed metal before gluing.

-After gluing, some binder/sealants need to be dried and solidified. The baking condition is (70-80)℃,20-30min.

Inhaling asbestos dust will cause damage to lung and lead to cancer. Please moisten asbestos while processing waste materials, and place it in sealed container with apparent mark for safe processing. /

If it’s necessary to cut or drill on asbestos material, please moisten the material first, and use manual or low-speed power tools only.

The released gas during charging is explosive, therefore do not carry out firing process near battery that is charging or has been charged sometime ago. Proper ventilation must be guaranteed.

Chemical materials such as solvents, sealants, adhesives, coatings, resin foams, battery acid, engine coolant, brake fluids, fuels, lubricants and greases should be used very much note. They can be poisonous, harmful, aggressive, irritating or highly flammable, with highly dangerous odors and dusts.

The effects of long-term overexposure to a chemical environment may be immediate or chronic, transient or permanent, cumulative, superficial, life-threatening or may affect lifespan.

Carefully read and follow the warnings and cautions on the container of origin and any accompanying flyers, posters or other instructions for use, as well as the health and safety information sheets for the ingredients, which are obtainable by the manufacturer.

After getting physical contact with chemical materials, remove it from the skin and clothing as soon as possible, and immediately replace the heavily immersed clothing and thoroughly clean it.

Strictly follow the work instructions and wear protective clothing to avoid direct contact with the skin and eyes.

It must be cleaned before handling breaks, eating, smoking, or using the washroom while handling chemical materials.

Keep working areas clean, tidy and do not spill chemicals.

Unless specified by the manufacturer, chemical materials can not be mixed at will; some chemicals can form other toxic or harmful chemicals that can release other toxic and harmful gases when mixed and can cause explosions and other accidents.

Do not spray chemical materials in a closed environment.

Unless instructed by the manufacturer, chemical materials should not be heated as some chemicals are highly flammable while others may emit toxic and noxious gases.

Do not allow the chemical container to remain open and the emitted gas may accumulate to a toxic, hazardous or explosive level. Some gases are heavier than air and accumulate in confined spaces.

Chemicals can not be loaded into unlabeled containers.

Do not use chemicals to clean hands and clothing. Chemicals, especially solvents and fuels, can dry the skin, cause allergies, cause inflammation of the skin or directly absorb toxic and harmful substances through the skin, which can affect your health.

Unless the container has been cleaned under supervision, otherwise do not use empty containers for storing other chemical materials.

Do not smell chemical materials at will Short-term exposure to high concentrations of gas may still lead to poisoning or injury

Powder, dust, and dust may be irritating, harmful or toxic. Avoid inhalation of powdered chemicals and dust raised by dry rubbing operations. Wear respiratory mask guards to prevent inhalation of dust if ventilation is poor.

Fine dust of combustible material may cause the danger of explosion and avoid explosion and sources of ignition.

Failure to use the electrical equipment correctly or abuse the equipment in good condition may result in electric shock.

Be sure to maintain the electrical equipment within the specified time and regular testing. Faulty equipment should be marked and preferably moved outside the work area.

Do not expose the wires, cables, plugs and jacks to wear, kinks, cuts, cracks, or other damage. Do not allow electrical equipment and wires to contact with water.

Ensure that the electrical equipment is protected by the correct fuse.

Misuse of electrical equipment is prohibited, and do not not use any device with hidden trouble, because the result may affect personal safety.

Ensure that the cable for mobile electrical equipment will not be pinched and damaged.

Basic first-aid training must be performed on specialized electrical operators.

In the event of an electric shock:

Turn off the power before touching the victim.

If you can not turn off the power, use dry insulator material to remove the victim's power.

If you have specialized emergency training, carry out on-site first aid immediately.

Request medical assistance.

Exhaust gas contains toxic and harmful chemicals such as carbon oxides, nitrogen oxides, acetaldehyde, lead and aromatic hydrocarbons. The engine can only be operated with suitable exhaust ventilation or general ventilation and with open space.

Used to isolate noise and sound.

The fibrous surface and sharp edges can cause skin irritation or scratch.

During operation, the instructions of the operating procedures and gloves should be worn to avoid excessive skin contact with the fibers.

Many materials related to vehicle maintenance are extremely flammable. Some materials are toxic and harmful when they are burned.

Please follow fire safety practices when storing and disposing flammable materials or solvents, especially near electrical equipment or near welding areas.

Before using electrical and welding equipment, please make sure that there is no risk of fire

When welding or using heating equipment, prepare a fire extinguisher around the work area.

Well-trained first-aid personnels should be in the workplace in order to comply with the law.

If eyes are splashed, rinse with water for at least 10 minutes.

If the skin is contaminated, wash the contaminated area with soap and water.

If suffering frostbite, the area affected by frostbite should be immersed in ice or cold water.

Inhalation of toxic gases should be promptly transferred to fresh air. If adverse reactions persist, they should be taken to the hospital for medical attention immediately.

If you inadvertently mistakenly suck the liquid, you should inform the physician of the information marked on the container or label, unless the instructions on the label, or not blindly guide.

Cured foam is a cushion for seating and decoration.

Follow the manufacturer's instructions.

Components that haven’t been chemically effected are irritating and may be harmful to the skin and eyes. Wear gloves and goggles during operation.

Persons with chronic respiratory diseases, asthma, bronchial problems, or those with genetic allergies should not handle or approach uncured material.

Their spare parts, vapors or sprays will cause immediate irritation and allergic reactions and can be toxic and harmful.

Remember not to breathe vapor or spray, these materials must be used in a well-ventilated and breathable protected. Do not remove the mask immediately after spraying.

Wait for vapor to completely dissipate before removing.

The uncured components and the matured foam are burned to produce toxic and harmful gases. During the foam operation, unless the vapor or spray has been completely removed, no smoking, no open flame, no electrical equipment, no foam, or special thermal cutting of foams should be done in a well-ventilated environment.

Minimize direct skin contact with the fuel. If exposed, wash the contacted area with soap and water immediately.

Extremely flammable - follow no-smoking regulations.

Accidental swallowing can cause mouth and throat irritation, and stomach absorption can lead to generalized weakness and confusion. A small amount of gasoline can affect a child's life and safety.

Therefore, it is very dangerous if the liquid enters lungs.

Gasoline will cause dry skin. Long-time or frequent contact will cause skin allergies and dermatitis. The fuel can cause severe pain if entering into eyes.

Motor gasoline may contain a large amount of benzene, which can cause poisoning if inhaled. Therefore the concentration of gasoline vapor must be kept low, as high concentrations of gasoline vapor can cause

Stimulation of the eyes, nose and throat, nausea, headache, frustration and drunken physical discomfort. Extreme concentrations of gasoline vapors can lead to rapid loss of consciousness.

In the treatment of gasoline, it is necessary to maintain good ventilation, special attention to the operation in a confined space to avoid the risk of inhalation of gasoline vapor due to splashing.

Special attention should be paid when cleaning and maintaining gasoline storage equipment.

Gasoline can not be used as a detergent, and do not suck gasoline with mouth.

It is important that you always keep all your tools and equipment in good working condition and that you are working correctly. Remember that tools or equipment should not be used in ways that are contrary to their intended function. Equipment such as cranes, jacks, axles and chassis supports or slings

shall not be subjected to loads exceeding the maximum limit they can bear. Damage caused by overload does not necessarily appear immediately, yet may cause serious accidents the next time.

/

Do not use tools or equipment that has been damaged or is in poor working conditions, especially some high-speed equipment such as grinding wheels. Damaged grinding wheel will break without warning and cause serious injury.

Wear appropriate eye protection when using grinding wheel, chisel or sand blasting equipment. Appropriate breathing masks must be equipped when using sand-blasting equipment, handling asbestos-containing materials, or using spray equipment. There must be ventilation device to control the amount of dust, mist and fumes in the environment.

Avoid long-term exposure to mineral oil, all the lubricating oil and grease, which can irritate eyes and skin.

-Wear protective clothing, including impervious gloves.

-Do not wear highly engine oil-contaminated clothing and footwear. Uniform must be regularly cleaned and kept clean.

-Emergency treatment of open wounds should be promptly available.

-During working, try to apply the insulation cream on the skin, so as to avoid direct skin contact with the engine oil.

-Remove all engine oil by washing with soap and water. Apply a lanolin-containing protective agent that will help replace the natural oils that are removed from the skin.

If skin lesions occur, go to hospitals immediately for medical assistance.

-Before working, remove the residual grease on components as far as possible.

Goggles, such as chemical goggles or face shields, should be worn if possible in direct contact with the eyes; in addition, eye-wash equipment should be provided.

Used waste engine oil and oil filters should be recycled through authorized or licensed waste disposal dealers or waste engine oil recyclers. If you have any questions, you should promptly contact the relevant departments of the local competent authorities for disposal.

It is against the law to dump used engine oil directly into the ground, sewer or drain or water pipes.

Extremely decibel-level noise can occur while performing certain operations that can cause hearing damage. At this time, proper hearing protection should be equipped.

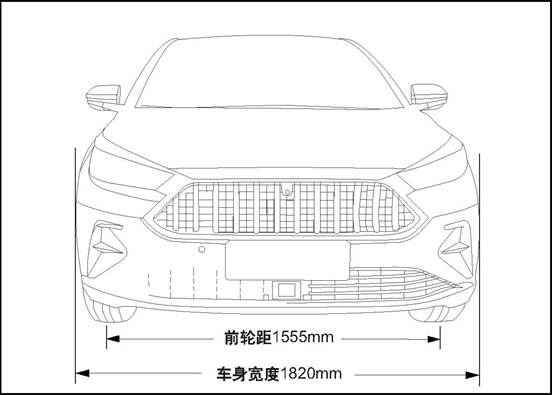

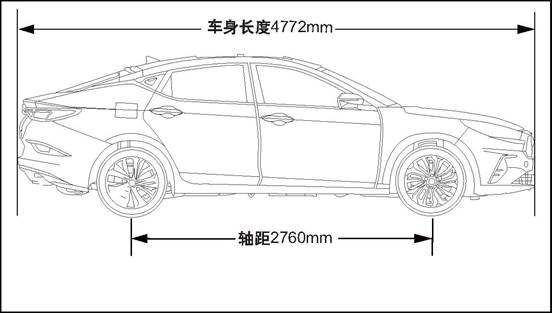

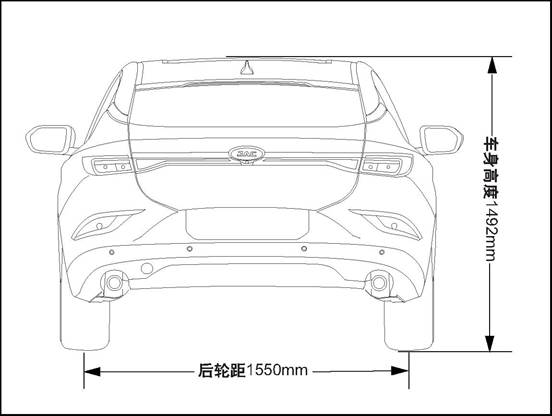

Front view

Front tread 15555 mm Bodywork width 1820 mm

Side view

Wheelbase 2760 mm Vehicle length 4772mm

Rear view

Rear tread 1550 mm![]()

|

Item |

Value |

Unit |

|

Total length |

4772 |

mm |

|

Total width |

1820 |

mm |

|

Total height (empty load) |

1492 |

mm |

|

Wheelbase |

2760 |

mm |

|

Front tread |

1555 |

mm |

|

Rear tread |

1550 |

mm |

|

Item |

1.5T+6MT |

1.5T+CVT |

Unit |

|

Passengers |

5 |

5 |

Person |

|

Curb weight |

1432 |

1440 |

kg |

|

Total weight |

1857 |

1865 |

kg |

|

Front axle’s load |

967 |

977 |

kg |

|

Rear axle’s load |

890 |

888 |

kg |

1 Vehicle Identification Number

Vehicle VIN is a legal identifier.

Vehicle identification number (VIN) position

There are several vehicle identification codes on the vehicle,and the following 10 are the most common:

1. Located on the instrument table at the lower left corner of the windshield, visible through the windshield.

2. Under the front passenger seat.

3. In the vehicle glove box.

4. On the engine cover.

5. On the front side of right-front door inner panel

6. Lower side of left B-column

7. On the front of the left front door inner plate

8. On the upper side of tailgate inner panel

9. Refer to ECU data.

10.Refer to MP5 data.

1 Diagnostic information and procedures

Wind noise / air sound

△CAUTION When the technician checks the faulty location, the assistant should drive the vehicle. Otherwise, it may cause injuries.

You must test the car in the car, in order to accurately confirm the location of the wind noise. In general, wind noise has major and minor leaks. If all leaks are not repaired during the repair, wind noise can only be reduced and wind noise can not be completely eliminated. Test-drive maintenance staff must bring the following tools to help diagnose the specific location of wind noise:

Stethoscope

Masking tape

Stitch seam

Marker pen

Follow the procedure below to try the road:

Select a line, with east, south, west and north four different directions of the straight street.

Choose less traffic or less noise in the street, to avoid affecting the test.

The road test is conducted at the speed at which the customer believes the noise is most pronounced or noisy, and a speed limit of more than the legal limit is strictly prohibited. The wind noise emitted under the following conditions is external wind noise:

Wind noise can be heard immediately while driving down the window glass.

When the tape is attached to the various decorative seals and gaps, the wind noise disappears immediately. Internal wind noise is caused by air escaping from the vehicle and should be repaired as follows:

In determining the location of the leak, attach the tape to the body lock pillar relief valve. The air pressure will be formed immediately inside the car, and the wind noise will be enhanced.

Use a stethoscope to confirm the leak location.

Use masking tape to temporarily repair leaks.

Continue road test to confirm whether the wind noise is completely eliminated or other leaked parts.

After confirming all leaks by road test, return to the repair shop and make permanent repairs with professional and reasonable positioning methods and sealing materials.

Please check the following table for common abnormal noise and solutions:

|

No. |

Symptom |

Parts for check |

Solution |

|

1 |

The vehicle generates squeaky sound when the engine speed is high. |

Check whether insulation panel contacts vehicle’s bottom part |

Lift the vehicle and perform a visual inspection |

|

Bend the insulation panel slightly to create a gap between it and the bottom of the vehicle body. |

|||

|

2 |

The front of the vehicle squeaks when the weather is cold |

Check the balance bar isolation rubber sleeve |

Cold Road Test vehicle and pass the bumpy road, so that the front suspension can reach maximum travel. |

|

Remove the isolation rubber sleeve and tape the front stabilizer bar, reinstall the isolation rubber sleeve on the tape. |

|||

|

3 |

Bumpy rear bass issued by the boring abnormal sound |

Check if the spare tire in the luggage compartment is properly secured |

Open the luggage compartment and inspect the spare tire and driver's tools. |

|

Refit spare tires and truck tools. |

|||

|

Test vehicle to check whether abnormal sound has been eliminated. |

|||

|

4 |

The rear of the vehicle emits a glass percussion while traveling on a bumpy road |

Check the rear door lock is not properly adjusted |

Carry out road test to check this situation. |

|

Loosen the lock nut and adjust the lock. |

|||

|

5 |

The door squeaked |

Check if the harness connector inside the door trim panel creaks |

Tap the trim plate and carefully observe if you hear a squawk |

|

Remove the door trim and wrap the foam padding around the harness connector according to the actual vehicle conditions. |

|||

|

6 |

Squeaking when using the door |

Check door hinges for lack of lubrication. |

Push the door back and forth and listen carefully to check whether the door squeaks. |

|

Use rust inhibitor to lubricate the door hinge and apply grease. |

External wind noise

Repair methods of wind noise leak and water leakage are very close. The actual repair procedure depends on the type of sealing components being repaired.

Repair of abnormal sound

Abnormal sound comes mainly from the relative motion that should not exist between the vehicle parts. There are three ways to repair abnormal sound:

Firmly tighten the parts so that there is no relative movement of the vehicle during driving.

Separate parts so that parts do not come into contact with them at work.

Isolate parts so that there is no abnormal noise when parts move. A uniform surface with low-friction can be used to eliminate sticking slip between parts.

If you want to buy special tool, please contact 4S shop in each area of JAC. For contact information, please contact 4008889933.

|

No. |

Diagnosis device type |

Diagnosis device version |

Tool No. |

|

1 |

3G-X431 |

V11.70 |

JAC-T1Z002 |

1 Generator Assembly

2 Starter

3 Battery Tray

4 Battery Assembly

5 Battery Heat Shield

6 Left Front Door Lock Cylinder

Starting system is mainly made up of battery, ignition switch, starter, starting relay and related wire harness. As the main part of starting system, starter is consisted of direct current motor, solenoid switch and transmission mechanism. Direct-current motor introduces the current of the battery and rotate the drive gear of the starter;

The drive mechanism meshes the drive gear into the flywheel gear ring and can automatically come away after the starting of the starter; the connection of the starter wire harness is

controlled by a solenoid switch.

Charging system main parts contain: generator assembly( with voltage regulator inner), battery and battery charging indicator lamp.

The main function of the generator is to provide the electricity to all the electric appliances (beside the starter), and charge the battery when the generator works normally.

The generator is mainly made up of five parts:rotor, stator, voltage regulator, housing and end cover. Its rotor and stator use the principle of electromagnetic cutting to produce the electricity,

the produced alternating current is transfered into the stable direct current through the rectification and the voltage stabilization of the voltage regulator. Generator is driven by the engine through the engine belt and gear device.

The car uses maintenance-free batteries, the difference with the traditional battery is the battery cover without vent plug; except for the battery on both sides of the small vent outside, the battery is completely sealed. Ventilation holes can make a small amount of gas generated by the battery discharge, the battery electrolyte within the chemical reaction will produce a small amount of gas, if you do not set the exhaust hole, the battery internal pressure increases with the gas increases, when over the battery shell body limit, the shell will rupture.

Compared to the traditional battery, this battery has the following advantages:

No water need to be added with the use cycle.

Over-charge protection.

Not easy to leak electricity as the traditional battery.

Smaller weight and volume and bigger capacity.

In the whole electric system, the battery has three main functions:

Providing the starting power for the engine when start the vehicle.

Acting as the voltage stabilizer of the electric system.

When the generated electricity from the generator can not satisfy the need of the electric system, the battery can provide the electricity in a certain period.

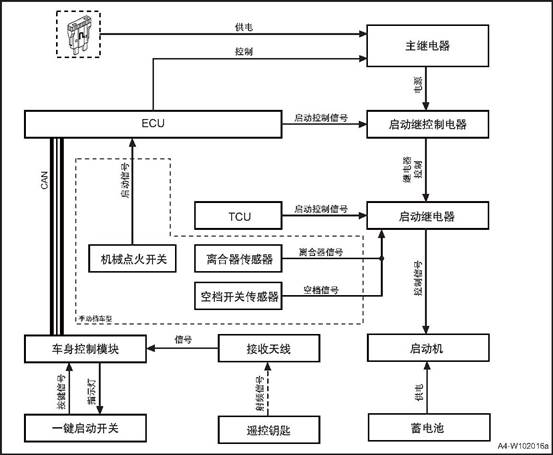

The body control module (PEPS controller is integrated into the body control module) checks whether the key is available by sending low-frequency signals. If the key is available, the key will send out a radio frequency response, and the receiving antenna will send the signal to the body control module. The body control module receives the start signal from button-start switch, and the body control module and ECU will Verify whether the starting conditions are met. If so, ECU controls the main relay to provide power to the start control relay. At the same time, the start control relay receives the start control signal from ECU, and the start control relay controls the start relay to work. At the same time, TCU gives the start relay a start signal, and the start relay starts to work. The electromagnetic switch of the starting motor is closed after being powered on, providing a closed circuit between the battery and the starting motor. The starting motor is grounded through the engine cylinder block. When the two conditions of power supply and grounding are met, the starting motor runs and the engine starts.

The manual transmission vehicle ECU receives the start signal of the mechanical ignition switch, ECU controls the main relay to provide power to the start control relay, at the same time, the start control relay receives the start control signal from ECU, the start control relay controls the start relay to work, and the start relay receives the transmission from clutch sensor and neutral switch signal, start the relay to work, thus driving the starter.

Button-start

Switch Start

control signal Start

control signal Main relay Power

Supply MT Model Signal Neutral

position sensor Neutral

position signal Clutch

signal Control Mechanical

ignition switch Clutch

sensor Antenna Body control module C4 Remote

control keys Battery Starter Starting relay Starting

control relay Starting control relay

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

No. |

fastener name |

torque(N·m) |

|

1 |

Battery tray fixing bolt |

- |

|

2 |

Battery pressing plate nut |

- |

Before repairing any electric part, the power supply mode of the start switch should in the OFF state, and all the electric loading must be OFF(closed), except the operation procedures has other explanation. If the tool or equipment is easily accessible to the exposed live electrical terminals, disconnect the battery negative cable. Violation of these safety instructions may result in personal injury or damage to vehicle parts.

Use the assist battery to ignite

1). If you need to use the auxiliary battery and jumper to start the engine, be sure to use 12V auxiliary battery. After connecting the battery jumper wire,

make sure that the jumper wire is clamped to the battery terminal and has good contact.

Prevent battery from over-discharge method

1) Always keep the battery surface (especially the top) clean and dry, the connection part of the port should be clean and tightened, if the car is not used for a long time,

should disconnect the battery negative terminal and regularly check the battery charging status.

a.Check if there are any after-sales retrofit devices that will affect start-up, charging or ignition system operation.

b.check accessible and viewable parts to check if there are obviously damaged parts or conditions that may cause possible fault.

c.Check the battery is installed correctly.

d.Test the state of the battery, the battery voltage shall not be less than 10.5V.

e.Check the relevant wire is damaged, check the starter motor, starter solenoid switch, starter switch, battery and all related ground connection is reliable.

f.Check generator installation is loose or improper installation, and transmission belt preload is normal, there is the possibility of skidding.

|

No. |

Fault symptoms |

Fault analysis |

Solutions |

Remark |

|

1 |

Engine cannot be started |

Ignition and fuel system faults |

Check the ignition and fuel system |

|

|

Starter power supply faults |

Check starter power supply |

|||

|

Starter faults |

Replace the starter |

|||

|

Starter solenoid switch faults |

Replace the starter solenoid switch |

|||

|

Engine mechanical binding |

Check the engine running related mechanical parts |

|||

|

Starter solenoid switch power supply wire harness faults |

Check relative wiring |

|||

|

Starter grounding faults |

Check the ground connecting wiring |

|||

|

Starter control power supply wire harness faults |

Check relative wiring |

|||

|

Starter relay fault |

Replace the starter relay |

|||

|

Ignition switch fault |

Replace the ignition switch |

|||

|

2 |

Engine can not stop working |

Starter relay fault |

Replace the starter relay |

|

|

Starter faults |

Replace the starter |

|||

|

Ignition switch fault |

Replace the ignition switch |

|||

|

3 |

Starter noise |

Flywheel gear ring broken(gearwheel craze, gearwheel lost, gearwheel wear and so on) |

Replace the flywheel gear ring. |

|

|

Flywheel broken(flywheel deformation) |

Replace the flywheel |

|||

|

Starter fault(gear craze or wear, shaft sleeve wear) |

Replace the starter |

|||

|

4 |

Charging indicator lamp always on |

Generator to ECU circuit loop |

Check relative wiring |

|

|

Generator power supply wire harness default |

Check relative wiring |

|||

|

Generator default |

Replace the generator |

|||

|

5 |

Charging indicator lamp can not light on |

Generator default |

Replace the generator |

|

|

6 |

Generator noise |

Generator default |

Replace the generator |

|

|

Generator installation fault |

Re-installation |

|||

|

Generator belt fault |

Re-installation or replacement |

|

Steps |

Inspection content |

Solution |

Decision specification |

Next step |

|

|

Yes |

No |

||||

|

1 |

Confirm the fault phenomenon |

Set the ignition switch on ST position, start the engine. |

Confirm if the engine rotates |

Next step |

Turn to step 4 |

|

2 |

Confirm the rotation situation of the engine |

Set the ignition switch on ST position, start the engine; read the engine rotation speed according to the instrument speed meter or diagnosis data. |

whether the engine rotation speed reaches the starting rotation speed. |

Check the engine ignition system and fuel supply system. |

Next step |

|

3 |

Check the battery voltage |

Set the ignition switch on ST position, start the engine, measure the battery voltage. |

Standard voltage value: larger than 10.5V |

Replace the starter |

Check the charging system |

|

4 |

Check the starter electromagnetic switch motion |

Set the ignition switch on ST position, start the engine to check the starter electromagnetic switch motion |

whether the starter electromagnetic switch works |

Next step |

Turn to step 8 |

|

5 |

Check the engine mechanical running |

Check the engine and belt drive system mechanical clamping stagnation(engine clamping stagnation, generator clamping stagnation) situation |

If it has clamping stagnation |

Repair the clamping stagnation part |

Next step |

|

6 |

Check resistance between the starter and the power supply |

Measure the circuit resistance between the battery and the starter motor. |

Standard value: <1Ω |

Next step |

Check and repair the cable |

|

7 |

Check the starter electromagnetic switch wire harness. |

Check if the starter electromagnetic switch wire harness has looseness, corrosion and damage. |

If the wiring connection is normal or not? |

Next step |

Check and repair the cable |

|

8 |

Check the starter control power supply voltage. |

Set the ignition switch on ST position, measure the voltage of starter wiring connector terminal. |

Standard voltage value: 11V ~ 14V |

Replace the starter |

Next step |

|

9 |

Check the starter control power supply wire harness resistance |

Measure the voltage value between the starter relay ER03 terminal 87 and starter wiring connector B08 terminal 1. |

Standard value: <1Ω |

Next step |

Check and repair the cable |

|

10 |

Check the starter relay motion |

Set the ignition switch on ST position, check the starter relay motion. |

If the starter relay actuates |

Next step |

Turn to step 14 |

|

11 |

Check the starter relay fuse SF10. |

Check the starter relay fuse SF10. |

Check if the fuse is blown |

Repair the wiring short circuit fault or replace the fuse. |

Next step |

|

12 |

Check the starter relay loading power supply voltage. |

Set the ignition switch on ST position, measure the starter relay ER03 terminal 30 power supply voltage. |

Standard voltage value: 11V ~ 14V |

Next step |

Check and repair the wiring. |

|

13 |

Check the starter relay fuse SF10 power supply circuit. |

Measure the wiring resistance between the starter relay fuse and battery. |

Standard value: <1Ω |

Next step |

Check and repair the wiring. |

|

14 |

Check the control wire voltage of the starter relay. |

Set the ignition switch on ST position, measure the starter relay terminal 85 voltage. |

Standard voltage value: 11V ~ 14V |

Next step |

Turn to step 16 |

|

15 |

Check the control wire ground of the starter relay. |

Measure the voltage value between the starter relay terminal 86 and grounding point E08. |

Standard value: <1Ω |

Next step |

Check and repair the wiring. |

|

16 |

Check ECU ignition signal. |

Set the ignition switch on ST position, measure ECU E19 terminal 45 power supply voltage. |

Standard voltage value: 11V ~ 14V |

Replace the ECU, the system is normal. |

Next step |

|

17 |

Normal system |

|

|

|

|

1. Open the engine cover

b. Disconnect the negative and positive cable of the battery with reference to the disconnection and connection of the battery cable

c. Remove the battery pack See Battery pack

d. Remove Battery assembly

![]() 1) Remove battery heat heat shield

1) Remove battery heat heat shield

2) Separate battery assembly and battery heat shield.

Check if the battery cable clamp is damaged. Replace any battery cable damaged or deformed by the cable clamp.

Check the battery chassis and battery holder hardware for damage. Replace any damaged parts.

Check the battery case for cracks or other damage that may cause electrolyte leakage. In addition, check whether the battery terminals are loose. Replace any damaged parts.

![]() Installation of Battery assembly

Installation of Battery assembly

a. Install the battery heat shield cover to the outside of battery assembly.

b. Install battery heat heat shield

c. Install Battery pressure plate

d. Connect the battery negative cable.

e. Close the engine compartment cover

1. Open the engine cover

2. Disconnect the negative harness of the battery refer to the disconnection and connection of the battery

c. Remove the battery pack See Battery pack

d. Remove the battery tray assembly See Battery assembly

e. Remove the battery tray assembly

![]() 1)Disconnect the engine control

module harness connector 1.

1)Disconnect the engine control

module harness connector 1.

2) dismantle the 4 fixing bolts of engine control module and take off the engine control module.

![]() 3). Remove the 4 bolts that fix the

battery tray assembly.

3). Remove the 4 bolts that fix the

battery tray assembly.

4) Take down the battery tray assembly.

a. Install the battery tray assembly

![]() 1). Install the 4 bolts that secure

the battery tray bracket assembly.

1). Install the 4 bolts that secure

the battery tray bracket assembly.

![]() 2) Mount the 4 fixing bolts of

engine control module and take off the engine control module.

2) Mount the 4 fixing bolts of

engine control module and take off the engine control module.

3)Connect the engine control module harness connector 1

b. Install battery assembly.

c. Install battery keep plate

d. Connect the battery negative cable.

e. Close the engine compartment cover.

1. Open the engine cover

![]() 2. Dismantle battery keep plate assembly.

2. Dismantle battery keep plate assembly.

1) Remove the 2 nuts fixing battery keep plate assembly.

![]()

![]() 2)

Take out battery keep plate assembly.

2)

Take out battery keep plate assembly.

![]() Install battery keep plate

Install battery keep plate

1) Install battery keep plate.

2) mount the 2 nuts fixing battery keep plate assembly.

![]()

![]() 2.

Close the engine cover

2.

Close the engine cover

1. Make sure the ignition is off

2. Open the engine cover

3. Disconnect the battery negative cable.

![]() 1) Disconnect the battery negative

cable nut

1) Disconnect the battery negative

cable nut

2) Remove the battery negative cable from the battery.

![]()

![]() 4 Disconnect the negative port of

the battery

4 Disconnect the negative port of

the battery

1) Open the battery positive electrode protection cover.

![]() 2) Loosen the battery positive electrode nut.

2) Loosen the battery positive electrode nut.

3) Remove the battery positive cable from the battery.

![]() 1. Connect the battery positive cable.

1. Connect the battery positive cable.

1) Connect the battery positive cable.

2) Tighten the battery positive cable nut.

3) Install the battery positive electrode protection cover.

![]() 2. Connect the battery negative cable.

2. Connect the battery negative cable.

1) Connect the battery negative cable.

2) Tighten the battery negative cable nut.

![]()

![]() 3.

Close the engine cover

3.

Close the engine cover

1. Remove the key gear piece

![]() 1). Press the button on the key,

and pull out the key tooth piece upward.

1). Press the button on the key,

and pull out the key tooth piece upward.

1. Install the key tooth piece

![]() 1). Insert the key tooth piece into

the key.

1). Insert the key tooth piece into

the key.

1. Open the left front door

2. Remove the left front door cylinder

![]() 1) Open the rubber cover 1

1) Open the rubber cover 1

2) Insert the mechanical key into the removal port of the lock cylinder cover, and pry down the left front door lock cylinder cover 2

![]() 3) Remove the left front door lock

cylinder fixing bolt.

3) Remove the left front door lock

cylinder fixing bolt.

![]() 4) Use a tool to pry down the left

front door cylinder.

4) Use a tool to pry down the left

front door cylinder.

1. Install left front door lock cylinder

![]() 1) Put the left front door lock

cylinder at the installation position

1) Put the left front door lock

cylinder at the installation position

△Attention: Keep the left front door cylinder clean.

![]() 2)Install the one left front door

lock cylinder fixing bolt.

2)Install the one left front door

lock cylinder fixing bolt.

![]() 3) Install the left front door lock

cylinder cover 2

3) Install the left front door lock

cylinder cover 2

4) install the rubber cover 1

2. Close the left front door

1. Open the engine cover

2. Disconnect the battery negative cable.

3 dismantle generator assembly

1) Remove the drive belt

2) Disconnect generator assembly wire harness connector 1.

3) Remove the charging cable fixing nut 2 of generator assembly and take off the charging cable.

![]() 4) Remove the two fixing bolts 3 of

the generator.

4) Remove the two fixing bolts 3 of

the generator.

5) Remove generator assembly

1 install generator assembly

1) Put generator assembly at the installation position

2) Install the 2 bolts 3 that fix the generator assembly.

3) Mount the charging cable fixing nut 2 of generator assembly and tighten it.

![]() 4) Connect generator assembly wire

harness connector 1.

4) Connect generator assembly wire

harness connector 1.

5) Install the drive belt.

2). Connect the battery negative cable.

3. Close the engine compartment cover

1. Open the engine cover

2. Disconnect the battery negative cable.

3. Dismantle the starter

![]() 1)Disconnect the starter control

wire harness connector 1.

1)Disconnect the starter control

wire harness connector 1.

2) Remove fixing nut 2 of power cord.

![]() 3) Remove the 2 fixing bolts of

starter

3) Remove the 2 fixing bolts of

starter

4) Take down the starter.

1 Install starter

![]() 1) Put the starter at the

installation position

1) Put the starter at the

installation position

2) install and tighten the 2 fixing bolts of starter

![]() 3) Mount the fixing nut 2 of starter power cord.

3) Mount the fixing nut 2 of starter power cord.

4) Connect the starter control wire harness connector 1.

2). Connect the battery negative cable.

3. Close the engine compartment cover

1. Front Low Frequency Antenna

2. Button Type Ignition Switch

3. Electronic Steering Column Lock

4. Standby Antenna

5. Door handle Low Frequency Antenna

6. Middle Low Frequency Antenna

7. Rear Low Frequency Antenna

8. Anti-theft Induction Coil

Passive Entry & Passive Start (PEPS) means a keyless entry and keyless start system that uses state-of-the-art RFID radio frequency technology and a vehicle identification code recognition system to provide a comfortable and completely new driving experience with user-friendly convenience.

PEPS system includes: PEPS controller (integrated in BCM), intelligent key (ID), Button start switch, vehicle low-frequency antenna (LF), standby antenna, door handle antenna (HSU), electronic steering column lock (ESCL), etc.

|

Part Name |

Instructions |

|

PEPS controller |

PEPS controller is the heart of the PEPS system and is responsible for interacting with other system information and performing related actions. Meanwhile, the PEPS controller is also the power management system, which is responsible for the power state management of the whole vehicle. The ACC and ON power sources of the whole vehicle are all from PEPS. |

|

Smart key |

Smart key: is a PEPS system tool for computer-human interaction (1) The low-frequency interaction between the low-frequency antenna of the door handle and the low-frequency antenna of the rear guard and the PEPS controller is carried out. At the same time, the identity of the key is confirmed through the high-frequency to realize keyless entry into the vehicle; (2) Conduct low-frequency interaction with the PEPS controller through the low-frequency antenna in the car to confirm the location and legitimacy of the key, and confirm the identity of the key through the high-frequency to prepare for keyless startup. |

|

Button-start Switch |

Button-start switch is the tool for human-machine interaction of PEPS system, customer sends power switching to PEPS system though the button, engine starting or closed request. |

|

Vehicle low-frequency antenna |

The low-frequency antenna in the vehicle is the vehicle low-frequency signal transmitting tool of the PEPS system. |

|

Standby antenna |

The spare antenna is used to place the key beside the smart key when there is no power to carry out passive near-field low-frequency communication and achieve the purpose of key authentication. Standby antenna is also required for off-line matching. |

|

Door handle antenna |

The door handle antenna is used to generate low-frequency signal when the user presses the door handle button to search for the smart key within the signal range, so as to achieve the goal of key identity authentication. |

|

Electronic steering column lock (ESCL) |

The function of electronic steering column lock is similar to the common ignition lock function, after the vehicle stops to lock the vehicle steering string, improve the performance of vehicle anti-theft prevention. |

PEPS and ESC: PEPS acquires CAN network vehicle speed signal from ESC to determine whether the vehicle is still or running.

PEPS and EMS: PEPS obtains clutch state, neutral position, engine speed, engine running state, engine start&stop working state, anti-theft authentication request signal from EMS, realizes anti-theft function, start&stop function, etc.

PEPS and ICM: The information between PEPS and ICM is exchanged, and the alarm prompt information is exchanged and displayed.

PEPS and BCM: PEPS interacts with BCM to realize the opening and closing of door locks and the lifting of windows and doors. Also, BCM is the gateway, transmit the signals sending from EMS, TCU, ESC, etc.

PEPS and TCU: PEPS gets the CAN network gear position information and hardwire P/N gear position signal from TCU to judge the state of the vehicle position as the system action condition. P gear switch: Provide P gear position signal, perform power on/off condition.

PEPS and brake switch/clutch switch: for the automatic vehicle, PEPS obtains the brake pedal status signal from the brake switch as the starting condition of the system. For the manual brake vehicle type, PEPS obtains the clutch pedal signal from the clutch switch as the starting condition of the system.

PEPS and ESCL: PEPS obtains the steering column lock state from ESCL, to judge the locking state or unlocking state of steering mechanism. ESCL and PEPS: ESCL obtains IG1 power hardwire signal from PEPS, to judge the vehicle power supply state.

ESCL and ESC: PEPS acquires CAN network vehicle speed signal and hardwire vehicle speed signal from ESC to determine whether the vehicle is still or running. ESCL and EMS: ESCL obtains the engine running state from EMS to judge the engine working condition.

ESCL and BCM: ESCL and BCM interacts with BCM to obtain the open and closed state of the door, the vehicle power supply state and the lock signal of BCM, and mainly realizes the lock and unlock action of the electronic steering column. Also, BCM is the gateway, transmit the signals sending from EMS, ESC, etc.

Unlock function: when the door handle is pressed, the door handle antenna triggers the key to authenticate with the peps controller. If the authentication is successful, the intelligent key can enter the performance and the PEPS controller will send the unlock request to the body controller, the door is unlocked.

Precautions:

1. Keyless unlock: after the remote control operation opens the door to release the vehicle alert state, please execute the opening action within 30s, otherwise, all doors (including the trunk) will automatically lock (increasing anti-theft secure).

2. Keyless unlock function limit: The unlock function does not work properly under the following conditions:

After pressing the micro switch on the outer door handle to perform the lock, press the micro switch again in 1.5s to not perform the unlocking action; easy to check if the vehicle door is locked

After the vehicle is locked by the central control lock, the keyless function will be disabled (increasing vehicle safety).

After the car is locked with a remote control, the keyless function will be disabled (increasing vehicle safety).

After the car is locked with a mechanical key, the keyless function will be disabled (increasing vehicle safety).

3. When there is a legal key in the vehicle, and use another key to perform keyless lock outside the vehicle, the vehicle will automatically be unlocked with alarm.

Lock function: after all doors are closed, when pressing the door handle button, search for the key on the side of the door handle, if there is no key, can not lock, if there is a key, do the key authentication and check whether there is a key in the car. When there are no keys in the car, the PEPS controller sends a lock request to the body controller, and the door is locked.

Precautions: When the left front door of the vehicle is not closed, the vehicle does not perform the lock action. The other three doors are not closed, press the door handle button, the vehicle can lock, but do not enter the state of defense.

/ After the door is closed, the vehicle enters the defensive state.

When pressing the suitcase button, search for the key outside the suitcase, if there is no key, can not unlock it, if there is a key, determine whether the key is also detected in the car. If this key is not detected in the car, the PEPS controller sends an unlock request. To the BCM, the trunk is unlocked.

Caution: When the key is in the trunk, and the trunk is closed manually, the vehicle will immediately disengage. The four-door unlock is accompanied by an alarm sound. Press the trunk unlock button and the trunk can be opened.

/

Engine start/stop: MT model step on the clutch pedal (AT model needs to step on the brake pedal), the low-frequency antenna in the vehicle starts to search the key, and the smart key sends the authentication information; For MT model, if clutch signal and neutral signal are correct, the start button will turn green. For AT model, if P switch signal and PN hard line signal are correct, start button will turn green; press the button, PEPS controller send anti-theft authentication to the EMS, when authentication passes, the PEPS controller makes start request to the EMS and EMS starts the vehicle.

Precautions:

If the key is placed in the corner of the vehicle dashboard, there may be a case that the key cannot be verified even there is key (because it is outside the inspection area in the vehicle).

After verification in the vehicle, the vehicle/key stops sending signal (the next authentication is when the door opens).

In the running process of the vehicle, except for emergency stop, the starting button will not trigger the starting relay to engage when it is touched in other cases.

Put the key in the middle of the armrest box, step on the clutch pedal for MT model (step on the brake pedal for AT model), shift to the neutral gear (P gear), and press the button after the green light is lit with start button (→engine start) . When the clutch switch or brake switch is ON, the PEPS controller starts to confirm the key verification state in the vehicle. If the key is not detected in the car, the PEPS controller will trigger the standby antenna, and the key will be authenticated with the key. The authentication pass and other conditions are satisfied, the green light of the button will be lit. After pressing the button, PEPS controller authenticate engine controller, after verification sucessfully, the engine start.

Precautions:

1. Make sure that the key is in the specified location. If it is not in the specified location, the key may not be detected.

2. Power state switching:

With key and not step on clutch/brake pedal→ press PEPS button shortly → Power supply changes among ACC/ON/OFF after each press;

For AT model, when gear position is not in P, power supply can not be shut off. 3. Passive start:

When starting engine, don’t press start button for more than 10s.

For MT model, shift to P gear position when in neutral, do not press the brake pedal to press the start button for 15s, it can start the vehicle for emergency; For AT model, when in P gear position, do not press the brake pedal and press the start button for 15s, it can start the vehicle for emergency.

Passive start may not work in the following situations: Smart key is not inside the vehicle: The smart key battery is low; there are facilities nearby which release strong electromagnetic waves, such as TV towers, power stations, radio stations, etc.; smart key contacts to the metal object or is covered by the metal object.

4. Close the engine

Press and hold the start switch for 3s or press the start button 3 times continuously within 3s to shut down the engine for emergency.

When vehicle is running, closing the power supply will lose brake and steering power!

Remote control locking: all doors closed →Short press lock button→Door lock, turn signal flicker 1 time

Remote control unlocking: Short press lock button→Door lock, turn signal flicker 2 times

Remote control tail door: press the tail door button for more than 2s→turn signal flickers, press the tail door button to open the tail door. Remote control lifting window (if configured): Short press the lock key button to enter alert→ Long press the lock button until the window automatically goes up. Remote control lowering window(if configured): Short press the unlock key button to release the alert→ Long press the unlock button until the window automatically goes down

1. Remote control locking: when the left front door of the vehicle is not closed completely, the vehicle does not perform the lock action The other three doors are not closed, press the lock button on the remote control key, the vehicle can lock, but do not enter the state of defense. After the door is closed, the vehicle enters the defensive state.

2. Remote control unlocking: after the remote control operation opens the door to release the vehicle alert state, please execute the opening action within 30s, otherwise, all doors (including the trunk) will automatically lock.

3. Remote control limit: without turning off the vehicle power (ACC or ON), the remote control function can not work properly.