Overall

Description

I.

warning and precautions

(1)

warning and precautions

Definition of "Warning",

"Important Note" and "Attention”

The

diagnostic and maintenance procedures in this manual include general and

specific "warnings", "important notices" and

"cautions", and JAC is committed to providing maintenance information

to assist the after-sales service technician in the diagnosis and maintenance

system , so that the vehicle can run normally, but if the technician does not

operate as recommended, some programs may pose a risk to the technician.

"WARNING",

"IMPORTANT NOTES" and "CAUTION" are prepared to prevent the

occurrence of such hazards, but not all hazards are predictable. This

information is displayed in prominent positions in the maintenance manual. This

information is prepared to prevent the following:

·Causing

serious injury to people

·Vehicle

damage

·Unnecessary

vehicle maintenance

·Unnecessary

parts replacement

Improper

repair or replacement of vehicle parts

The definition of

"Warning"

When

you encounter a "warning", it asks you to take the necessary action

or to prohibit the action taken. If you ignore "warning", you may have

the following consequences:

·Causing

serious injury to people

If

the vehicle is improperly repaired, it will cause serious personal injury to

the driver and / or passenger of the vehicle.

The definition of

"important note"

"Important

note" requires special attention to the measures necessary or prohibited.

If you ignore the "important note", it will lead to the following

consequences:

·Vehicle

damage

·Unnecessary

vehicle maintenance

·Unnecessary

parts replacement

·Abnormal

operation or performance of the system or component being repaired

·Damage

related systems or components

·Damage

fasteners, basic tools or special tools

·Engine

coolant, lubricating oil or other essential liquid leakage

The definition of

"Attention”

The

"attention" statement emphasizes the necessity of a diagnostic or

maintenance procedure, and the purpose of the "attention" statement

is as follows:

Clear

procedure

Provide

supplementary information for completing a program

Clarify

the reason for an operation according to the recommended procedure

Provide

information that helps to complete the program in a more efficient way

Provide

the technician with past experience information to make the process easier

Warning about vehicle lift

△Warning To avoid vehicle damage,

serious personal injury or even death, when the main part is removed from the

vehicle and the vehicle is supported by an elevator, please use jack to support

the corresponding vehicle parts to be dismantled..

Warning about crash repair permission devices

△ Warning To avoid personal

injury when exposed to toxic flamings generated from wipes or electroplating

(zinc oxide) metal during grinding / cutting of any type of metal or sheet

molding, the working process must be operated in a well-ventilated area and

technician should equip permitted respirators, goggles, earplugs, welders

gloves and protective clothing.

Warning about helper driving

△

Warning When the technician checks the defective parts, the vehicle should be

driven by the assistant. Otherwise, it may cause personal injury.

Warning about disconnecting the battery

△

WARNING Before servicing any electrical parts, the ignition key must be in the

OFF or LOCK position and all electrical loads must be "OFF"

),

Unless otherwise stated in the operating procedure. If the tool or equipment is

easily accessible to the exposed live electrical terminals, disconnect the

battery negative cable. Violation of these safety instructions may result in

personal injury and / or damage to vehicles, vehicle parts.

△

Warning If you repair the airbag, you must disconnect the battery negative at least

90s in order to carry out other operations.

Warnings

of inhaling R134a

△Warning Please Avoid absorbing

A/C refrigerant ,134a(R134a),Lubricating oil steam or fog otherwise it will

stimulate the eyes, nose, and pharynx. Please carry out operations in area with

proper ventilation. When exhausting R134a from A/C system, please use service

facilities that meet the standard of SAEJ2210 If unexpected fluid leak happens,

please ventilate workplace before continuing repair. For other information

concerning health and safety, please consult manufacturer of refrigerant and

lubricating oil for details.

Warning

about collision cut

△

Warning please cut the recommended parts only, otherwise it will damage the

integrity of the vehicle structure, and may cause personal injury in the event

of vehicle collision.

Warnings

of cracks on windows

△ Warning If crack appears on the

window, yet the window is intact, please use protective glue tape and stamp the

tape on the window in crossing type, so as to avoid further damage or personal

injury.

Warnings

of windows’ lifting

△Warning When the driver handle

the power window, the function of lifting the window fast may Cause personal

injury

Warning

about eye protection

△WARNING

In the course of this procedure, licensed goggles and gloves should be worn to

reduce the risk of personal injury.

Warnings

of noise-insulating foam material

△ Warning If fire is needed during

repair process, the noise-insulating foam material with a distance of 152.4mm

within the fire must be cleared. When re-installing foam material, please avoid

inhaling smog, or your health will be affected.

Warnings

of glass and metal sheet

△

Warning In the course of processing glass or metal sheet with sharp or rough

edge, licensed goggles and gloves should be equipped to reduce the risk of

personal injury.

Warning

of halogen bulb

△

Warning high-pressure gas exist inside the bulb. Improper operation may cause

bulb’s explosion. To avoid personal injury:

Turn

off light switch and cool down the bulb before replacing bulb

Keep

the light switch shut down until the bulb has been replaced

Please

equip goggles while replacing halogen bulb

While

handling bulb, please hold the base part only and avoid contact with glass

The

bulb should be kept away from dust and moisture

Please

scrap the aged bulb in correct procedures

The

halogen bulb should be kept away from children

Warning

about moving parts and hot surfaces

△

WARNING When working around the running engine, avoid contact with moving parts

and hot surfaces to prevent personal injury.

Warning

about goggles and gloves

△ WARNING Do not wear goggles and

gloves when removing exhaust system parts, otherwise rusting and sharp edges

from worn parts of the exhaust system can cause serious personal injury.

Warning

about removal of tank cover

△ WARNING To avoid being burned, do

not remove the tank cover until the engine is cooled. If the tank and the

radiator are not cooled, remove the tank cover, the cooling system will release

hot high pressure liquid and steam.

Warning

about road test

△WARNING Please test vehicle with

your safety guaranteed and follow traffic regulations. Do not attempt any

operation that may endanger vehicle control. Violation of these safety

instructions may result in serious personal injury and vehicle damage.

Warning

about goggles and fuel

△

Warning When processing fuel, be sure to equip goggles to prevent oil from

splashing into the eyes.

Airbag

system

△

Warning Airbag system has been equipped on this vehicle. Failure to carry out

correct operation procedures may cause following situations:

Unexpected

airbag explosion

Pre-tightener

spark-off

Person

injury

Unnecessary

repair of airbag system

△

Warning please obey the following instructions to avoid the situations

mentioned above:

Please

refer to the overview of airbag system, and confirm whether repairing

operations are carried out on airbag system’s parts and circuits.

Please

secure the airbag system if you are carrying out repair on airbag system’s

parts and circuits.

Warnings of the high-temperature on released airbag

module

△

Warning when the airbag is released, the metal surface of airbag system module

will be very hot. To avoid fire accident and personal injury:

Make

sure the metal surface is fully cooled down for a certain time before touching

Do

not put the released airbag system module near any inflammable objects.

Warnings

on the clock spring of airbag system

△ Warning incorrect assembly of

clock spring may cause damage to the inner spiral coil, which will cause

failure of coil and airbag module, and lead to potential personal injury.

Warnings

of airbag module’s scrapping

△

Warning to avoid unexpected release of airbag and personal injury, do not

operate the unreleased airbag module as scrapped objects in workplace. If the

sealing container is damaged during scrapping process, some materials in the

unreleased module may cause illness or personal injury. Please scrap the

unreleased airbag module by following releasing procedures.

Warnings

of airbag module’s handling and storing

△

Warning while transporting unreleased airbag module:

Do

not lift the wire or connector on airbag module

Ensure

the airbag’s opening hasn't been put toward you or other people.

△ Warning while storing unreleased

airbag module, ensure the airbag's opening is not facing the surface of airbag

itself. The opening cannot be faced down, and no object should be put on airbag

module. Enough space should be provided for airbag’s unexpected release so as

to avoid personal injury.

Do

not soak the unreleased airbag module into water or other fluids. Do not place

the unreleased airbag module near fire or high-temperature area in case of

personal injury caused by airbag’s unexpected release.

Warnings

of handling collision sensor of airbag system

△ Warning Do not shake or knock the

collision sensor of airbag system. Before charging collision sensor, make sure

the sensor has been fixed tightly.failure to obey correct assembly procedures

may cause unexpected release of airbag and personal injury.

Important

notes of engine’s lifting

△

Important notes: do not fix the lifting jack under oil sump, stamping parts or

crankshaft belt pulley under any circumstance.

Improper lifting may cause damage

to vehicle parts.

The

important precautions for the removal of the logo on exterior trim

△

Important Note: while removing logo / nameplate, please use plastic tool with

flat edge to avoid damage on paintwork

Important

note of Fasteners

△

IMPORTANT NOTE: Please use the correct fastener in the correct position.

Replace the part number of the fastener must be correct, need to replace the

fastener or need to use

Thread locking glue or sealant

fasteners are specified in the maintenance procedure, and no paint, lubricating

oil or corrosion inhibitor may be used on the fastener or fastener connection

surface unless otherwise stated.

These coatings affect the torque

and clamping forces of the fasteners and damage the fasteners. When assembling

fasteners, be sure to use the correct fastening sequence and tightening torque

to avoid damage to parts and systems.

Important

notes of handling electrostatic discharge and sensitive parts

△ Important Note: electrostatic

discharge (ESD) will cause damage to solid electric component. Not all components

that subject to ESD have been marked with ESD symbol. Therefore, please handle

electric components carefully. Please obey the following safety instructions to

avoid damage caused by ESD:

-Before

repairing electronic component, touch the metallic bonding point and release

the static inside body (especially after sliding vehicle seat)

-Do

not touch the exposed terminal. The terminal may be connected to circuit which

may be damaged by static.

-When

repairing connector, do not make tools contact the exposed terminal.

-Do

not dismantle parts from protective cap unless otherwise stated.

Avoid

following operations unless otherwise stated by diagnostic program:

-Bridging

or bonding of components or connectors

-When

connecting testing facility’s probes to all parts or connectors, connect

binding wire first before using test probes

Before

opening protective cap of component, please bind the component first. Do not

put the solid component on metallic worktable, television, radio or other

electric devices.

Important

notes on switching ignition lock to “OFF” while disconnecting battery

△ Important note: when

connecting/disconnecting battery cable, charger or jumper cable, make sure the

ignition switch is at “OFF”. Otherwise the control module or other electric

components may be damaged.

Important

precautions of not twisting or bending when installing the hose

△

IMPORTANT NOTE: The inlet and outlet hoses may not be twisted during

Installation and may not bend or deform the hose for ease of Installation, as

this may cause parts damage.

Parts

are damaged.

Important

notes of fault diagnosis tester

△

Important note: before diagnosing vehicle, please pay attention to following

situations or the control module may be damaged.

-Make

sure the software version of tester and terminal are latest

-The

vehicle battery must be fully charged and the battery’s voltage should be

between 12-14V

The

connection of tester and terminal cable should be tight

While

programming control module, the charger shouldn’t be connected to battery

Important

notes when steering wheel is in limit position

△

Important note: the lasting time for steering wheel at its limit position

shouldn't exceed 5 seconds, otherwise the steering pump may be damaged.

Important

note of testing probe

△

Important Note: do not insert the probe of testing facility (digital multimeter

and etc.) into wire connector or the terminal of fuse box. The diameter of

testing probe will deform most terminals. Deformed terminals have poor contact,

which may cause system failure. Make sure to apply special tool and test

terminal from front side. Do not use clip or other substitutes to test the

terminal.

△

Important note: while using special tool to test components, make sure the

testing adapter can match to the dimension of terminal. Do not choose adapter

by eyeballing, as some terminal’s hole may be bigger than that of actual

terminal.

Choose a terminal test adapter, as

some connector terminals may appear to have larger holes than the actual

terminals in the hole. Using a large terminal test adapter can damage the

terminals

Important

notes of damage on windows’ edge

△

Important note: to avoid damage on vehicle windows caused by exposed edge, the

window must be 1mm lower than the surface of metal sheet to avoid the damage.

II.

vehicle inspection

(1)

projects should be checked when operating the vehicle

Honk

operation.

Please

press the honk occasionally to ensure the honk is working well. Check all

buttons.

Operation

of the brake system

While braking, please

check whether abnormal noise/sound, increase of brake pedal’s stroke or

repetitive lane departure exists. Furthermore, if the brake warning light keeps

lighting or flickering, some failures may exist inside brake system.

(2)

projects should be checked when fuel-charging

Oil/fluid

loss of all systems except for windshield washer means the system has failure.

Please check and repair system immediately.

Check the liquid level of cleaning agent of front

windshield glass

Check

the liquid level of cleaning agent in liquid reservoir, and add cleaning agent

if necessary.

(3) project should be checked at

least once a month

Operation

of vehicle light

Check

the operation of license lamp, headlamp (low/high beam), parking lamp, fog

lamp, tail lamp, brake lamp, steering lamp, reversing lamp and hazard warning

lamp.

Oil

leak check

After the vehicle has

been parked for a period of time, please check regularly whether water, engine

oil, fuel or other fluid exist under the vehicle. Water-dripping is a normal

phenomenon when the air conditioning system is used . if fuel leak or smoking

is detected, please check reasons and eliminate fault timely.

(4) projects should be checked at

least twice a year

Door and window seal lubrication

Apply

a layer of silicone grease to the seal with a clean cloth.

(5) projects should be checked at

least once a year

Status and operation of safety belt

Check

safety belt system, including the strap, buckle, lock plate, retractor, guide

ring and fixing device.

Storing of spare tire and lifting jack

Beware of the crunching

sound appeared in vehicle’s rear part. Spare tire, lifting device and tools

must be fixed all the times. Please use engine oil to lubricate the ratchet or

spiral device of lifting jack after use.

Key

lock maintenance

Lubricate

key cylinder

Maintenance

of vehicle body’s lubrication

Lubricate all hinges on

vehicle doors, engine cover, oil filler cap, tail door, plunger latch, glove

box and control console. All components of folded seats need to be lubricated.

Rinsing

of vehicle’s bottom part

First, loosen the

deposit sediment gathered around vehicle’s sealed area. Then use clean water to

rinse vehicle’s bottom. After winter, the vehicle’s bottom should be cleaned

once a year at least. Rinsing vehicle’s bottom can remove the corrosive

material that can be used for deicing or dust-proof.

III. Lifting the vehicle

(1) to lift the vehicle

Please

refer to "Warnings about vehicle lift" in the "Warnings and

Precautions".

To

avoid personal injury, be sure to use the jack when you are working on a

vehicle that is only jack-mounted or under a vehicle. Put the cushion block of

rear lifter beneath the junction between the rear frame rail and side frame

rail.

△

Note that the rear lift block can not hit the sill plate to the outside of the

frame rails or the floor.

Put

the cushion block of front lifter beneath the junction between the rear frame

rail and side frame rail.

△

Note that the rear lift block can not hit the sill plate to the outside of the

frame rails or the floor.

IV. maintenance

(1) specifications

Oil/liquid

capacity

|

application

|

Specification

|

|

Refrigerant

|

480±20g

|

Recommended

oil/liquid and lubricating oil

|

application

|

Oil&liquid

/ lubricating oil

|

|

A/C

refrigerant

|

R134a

|

|

Windshield

cleaning agent

|

NC310-c

|

|

Hinge of engine

cover, vehicle door, oil filler cap and tail door

|

General

lithium-based grease for vehicle

|

|

sealing

strip for doors and windows

|

Silica-based

lubricating grease

|

(2)

regular maintenance instructions

The

normal use of the vehicle

The

maintenance items given in the maintenance plan has assumed that the vehicle is

used for the following purposes:

Passengers

and cargo are transported under the constraints indicated by the tire label at

the driver's door edge.

Drive

on the proper road surface and within the legal limits.

Description

of planned maintenance items

Maintenance items

listed in the maintenance items detailed below, in the implementation of the

following maintenance items, be sure to replace all parts and make all necessary

repairs before they can drive on the road, be sure to use the appropriate

fluids and lubricants.

Used for battery and other

materials’ cleaning.

Irritation or erosion for the eyes,

skin, smell and throat, and will cause burns to the human body and damage to

ordinary protective clothing.

Avoid splashing on eyes, skin and

clothing. Wear proper protective clothing, gloves and goggles to prevent

inhalation.

Be sure to include flushing

equipment nearby, such as eye wash bottles, shower pads, soap, etc., for

immediate relief in the event of splashes.

Marked signs of eye danger in a

prominent position.

(3) air bag

For highly inflammable or explosive

materials—please follow no-smoking rules

Air

bags are assembled as auxiliary safety system in steering wheel, seats of front

passengers, front dashboards and A column, B column and C column. A high-energy

propellant that can generate extremely high-temperature (2500℃ /4532 ℉) gas has

been equipped in the air bag expander.

This propellant is

sealed in inclosed components, and will filled into airbag after reacting with

airbag. During repair process, do not open airbag, because this will make

propellant contact airbag and cause hazard. If air-generator is found broken,

please equip full-protective clothing when processing spilled material.

When

airbag has been set off normally, please equip safety goggles and gloves during

processing.

The

released air bag should be processed according to relevant laws and regulations

in local area.

If

you have direct contact with ramification of air, please:

Wash

contacted part with water

Seek

medial assistance if necessary

Airbag

— operations should be done

For your safety, please

wear protective equipments before carrying out following operations; when

dismantling airbag, make sure the vehicle’s ignition switch is at “LOCK”. Pull

up the key and disconnect negative cable, then proceed disassembly process

after 90 seconds.

Store

the airbag components in straight position

When

storing, keep the airbag dry.

When

moving airbag components, do not touch electrode and keep airbag away from

body.

Place

airbag component with protecting cover facing up.

Check

whether airbag component is damaged

Disconnect

battery’s cathode cable when connecting airbag, and stand in the side of airbag

component after waiting 60 seconds.

Rectify

and maintain all devices accurately.

Wash

hands after processing the released airbag.

Airbag — operations should be avoided

Do

not store inflammable material or component together with gas-generator.

Do

not soak the unreleased airbag module into water or other fluids.

Do

not store gas-generator in area which has a temperature higher than 80 ℃ /176 ℉

Do

not store components upside down.

Do

not try to open the cover of gas-generator

Do

not expose gas-generator to fire or heat source

Do

not place other object on components’ protective cover

Do

not use damaged component

Do

not touch the component or gas-generator within 10 minutes after the airbag

component is set off

Do

not use electric probe on the circuit.

(4) A/C refrigerant

Physical

contact may lead to frostbite.

Please

follow the instructions provided by manufacturer. Do not make refrigerant

exposed to light, and wear proper goggles and gloves.

If your skin or eyes has contact with refrigerant, use

water to rinse the contacted area immediately. Use proper rinsing solution to

clean your eyes. Do not rub your eyes and seek medical assistance according to

actual situations.

A/C refrigerant — operations should be

avoided

Do

not store refrigerant in places that are exposed to sun or have heat sources

nearby.

When

filling refrigerant, do not keep refrigerant bottle straight. Keep the bottle’s

valve facing down.

Do

not expose refrigerant bottle exposed to frost or snow.

Do

not drop refrigerant bottle. Do not release refrigerant into air under any

circumstance. Do not blend refrigerant, like mixing R12

(dichlorodifluoromethane) and R134a (tetrafluoroethane)

(5)

binder and sealant

Important note of binder and

sealant

Before

applying binder and sealant, make sure the applied surface should be clean.

Please use specified cleaning agent to scrub the applied surface so as to

guarantee the binding effect. while applying sealant, do not let the glue

solution enter into thread's blind hole, as the glue solution will generate

hydraulic locking effect when the fastener is fastening, which will lead to

damage on fasteners and/or other components. Furthermore, the glue solution

will make fastener unable to acquire correct clamping force during fastening,

and deteriorate the sealant's performance. This will cause fasteners unable to

fasten correctly, loosen or separate components and cause severe damage to

engine or other components.

Health

and safety

Hazardous

materials exist in binder and sealant, and long-time contact with these

material will cause acute/slow disease, occupational disease, skin disease and

etc. While gluing, please use venting device to keep the ventilation in

workshop; during operation, please wear protective gloves, goggles and

clothings. After the process, please wash hands and keep the cleanness and

tidiness of workshop.

the

waste of wasted glue or solvent’s pollution should be cleaned timely. Long-time

accumulation is prohibited.

Products

should be stored in non-smoking area and keep cleanness while using. Please use

applying device or container to proceed working process as far as possible.

Important note of repair of binder and sealant

When

failure or accident happens on vehicle, it may cause vehicle’s deformation,

steel plate’s cracking and welding spot’s fall-off. It may cause partial damage

to engine, chassis or other assemblies and make binder/sealant’s fall-off and

damage. During the repair process, please choose proper binders according to

the component’s texture and functions. Some binder/sealants that may be used

during repair process have been listed follow for your reference during repair

process.

Repair

of vehicle body

When

the interior trim and steel plate of vehicle body are deformed or cracked, the binder

will fall off or be broken. Therefore the parts that applied with binder should

be fixed during repair process.

Please

use knife to clean the binder on vehicle body’s surface, and use alcohol to

scrub the remnant binder; please use specific cleaning agent to scrub the glued

parts to avoid the existence of remnant glue or other foreign material on

applying surface; then apply fixing binder on the original gluing part to glue

and seal components.

Parts’

repair

Some

parts (inner trim component, engine, gearbox and etc.) needs to be glued or

sealed if suffering damage. While applying sealant, please clean the binding

surface so as to avoid the negative effect of rag and crack.

Attentions

during process

The

binder/sealant can prevent water and dust from entering into vehicle, and is

corrosion-resistant The original sealing joints are apparent. If these joints

are broken, they need to be re-sealed. Please use binder/sealant with

high-viscosity while sealing the openings and joints. Please follow the instructions

of the chosen materials

-While

applying binder/sealant, precautionary measures must be taken to prevent

binder/sealant from entering into components’ opening (door lock, glass-lifting

groove, glass regulator and safety belt’s retractor) or other moving, rotary

components, especially parking brake’s drawing. After applying binder/sealant,

make sure all release holes of vehicle are open.

-When

processing, please wear specific protective goggles and gloves to prevent

personal injury.

-When

vehicle leaves factory and all metal sheets of vehicle have been coated,

repaired and replaced with new spare parts, please apply rust-proof base coat

on the surface of exposed metal before gluing.

-After

gluing, some binder/sealants need to be dried and solidified. The baking

condition is (70-80)℃,20-30min.

(6) asbestos

Inhaling

asbestos dust will cause damage to lung and lead to cancer.

Please

moisten asbestos while processing waste materials, and place it in sealed

container with apparent mark for safe processing.

If it’s necessary to cut or drill

on asbestos material, please moisten the material first, and use manual or

low-speed power tools only.

(7) acid liquor in battery

The

released gas during charging is explosive, therefore do not carry out firing

process near battery that is charging or has been charged sometime ago.

Proper

ventilation must be guaranteed.

(8) chemical materials

Chemical

materials such as solvents, sealants, adhesives, coatings, resin foams, battery

acid, engine coolant, brake fluids, fuels, lubricants and greases should be

used very much note. They can be poisonous, harmful, aggressive, irritating or

highly flammable, with highly dangerous odors and dusts.

The effects of

long-term overexposure to a chemical environment may be immediate or chronic,

transient or permanent, cumulative, superficial, life-threatening or may affect

lifespan.

Chemical Materials - What to do

Carefully read and

follow the warnings and cautions on the container of origin and any

accompanying flyers, posters or other instructions for use, as well as the

health and safety information sheets for the ingredients, which are obtainable

by the manufacturer.

After

getting physical contact with chemical materials, remove it from the skin and

clothing as soon as possible, and immediately replace the heavily immersed

clothing and thoroughly clean it.

Strictly

follow the work instructions and wear protective clothing to avoid direct

contact with the skin and eyes.

It

must be cleaned before handling breaks, eating, smoking, or using the washroom

while handling chemical materials.

Keep

working areas clean, tidy and do not spill chemicals.

Chemical Materials - Actions to be avoided

Unless specified by the

manufacturer, chemical materials can not be mixed at will; some chemicals can

form other toxic or harmful chemicals that can release other toxic and harmful

gases when mixed and can cause explosions and other accidents.

Do

not spray chemical materials in a closed environment.

Unless instructed by

the manufacturer, chemical materials should not be heated as some chemicals are

highly flammable while others may emit toxic and noxious gases.

Do not allow the

chemical container to remain open and the emitted gas may accumulate to a

toxic, hazardous or explosive level. Some gases are heavier than air and

accumulate in confined spaces.

Chemicals

can not be loaded into unlabeled containers.

Do not use chemicals to

clean hands and clothing. Chemicals, especially solvents and fuels, can dry the

skin, cause allergies, cause inflammation of the skin or directly absorb toxic

and harmful substances through the skin, which can affect your health.

Unless

the container has been cleaned under supervision, otherwise do not use empty

containers for storing other chemical materials.

Do

not smell chemical materials at will Short-term exposure to high concentrations

of gas may still lead to poisoning or injury

(9) dust

Powder, dust, and dust

may be irritating, harmful or toxic. Avoid inhalation of powdered chemicals and

dust raised by dry rubbing operations. Wear respiratory mask guards to prevent

inhalation of dust if ventilation is poor.

Fine

dust of combustible material may cause the danger of explosion and avoid

explosion and sources of ignition.

(10) electric shock

Failure

to use the electrical equipment correctly or abuse the equipment in good

condition may result in electric shock.

Be

sure to maintain the electrical equipment within the specified time and regular

testing. Faulty equipment should be marked and preferably moved outside the

work area.

Do

not expose the wires, cables, plugs and jacks to wear, kinks, cuts, cracks, or

other damage. Do not allow electrical equipment and wires to contact with

water.

Ensure

that the electrical equipment is protected by the correct fuse.

Misuse

of electrical equipment is prohibited, and do not not use any device with

hidden trouble, because the result may affect personal safety.

Ensure

that the cable for mobile electrical equipment will not be pinched and damaged.

Basic

first-aid training must be performed on specialized electrical operators.

In

the event of an electric shock:

Turn

off the power before touching the victim.

If

you can not turn off the power, use dry insulator material to remove the

victim's power.

If

you have specialized emergency training, carry out on-site first aid

immediately.

Request

medical assistance.

(11) waste gas

Exhaust gas contains

toxic and harmful chemicals such as carbon oxides, nitrogen oxides,

acetaldehyde, lead and aromatic hydrocarbons. The engine can only be operated

with suitable exhaust ventilation or general ventilation and with open space.

(12) fiber isolation

Used

to isolate noise and sound.

The

fibrous surface and sharp edges can cause skin irritation or scratch.

During

operation, the instructions of the operating procedures and gloves should be

worn to avoid excessive skin contact with the fibers.

(13) fire

Many

materials related to vehicle maintenance are extremely flammable. Some

materials are toxic and harmful when they are burned.

Please

follow fire safety practices when storing and disposing flammable materials or

solvents, especially near electrical equipment or near welding areas.

Before

using electrical and welding equipment, please make sure that there is no risk

of fire

When

welding or using heating equipment, prepare a fire extinguisher around the work

area.

(14) first aid

Well-trained

first-aid personnels should be in the workplace in order to comply with the

law.

If

eyes are splashed, rinse with water for at least 10 minutes.

If

the skin is contaminated, wash the contaminated area with soap and water.

If

suffering frostbite, the area affected by frostbite should be immersed in ice

or cold water.

Inhalation

of toxic gases should be promptly transferred to fresh air. If adverse

reactions persist, they should be taken to the hospital for medical attention

immediately.

If

you inadvertently mistakenly suck the liquid, you should inform the physician

of the information marked on the container or label, unless the instructions on

the label, or not blindly guide.

(15) foam - polyurethane

Cured

foam is a cushion for seating and decoration.

Follow

the manufacturer's instructions.

Components

that haven’t been chemically effected are irritating and may be harmful to the

skin and eyes. Wear gloves and goggles during operation.

Persons

with chronic respiratory diseases, asthma, bronchial problems, or those with

genetic allergies should not handle or approach uncured material.

Their

spare parts, vapors or sprays will cause immediate irritation and allergic

reactions and can be toxic and harmful.

Remember

not to breathe vapor or spray, these materials must be used in a

well-ventilated and breathable protected. Do not remove the mask immediately

after spraying.

Wait for vapor to completely

dissipate before removing.

The uncured components

and the matured foam are burned to produce toxic and harmful gases. During the

foam operation, unless the vapor or spray has been completely removed, no

smoking, no open flame, no electrical equipment, no foam, or special thermal

cutting of foams should be done in a well-ventilated environment.

(16) fuel

Minimize

direct skin contact with the fuel. If exposed, wash the contacted area with

soap and water immediately.

Gasoline

Extremely flammable - follow

no-smoking regulations.

Accidental swallowing can cause

mouth and throat irritation, and stomach absorption can lead to generalized

weakness and confusion. A small amount of gasoline can affect a child's life

and safety.

Therefore, it is very dangerous if

the liquid enters lungs.

Gasoline

will cause dry skin. Long-time or frequent contact will cause skin allergies

and dermatitis. The fuel can cause severe pain if entering into eyes.

Motor

gasoline may contain a large amount of benzene, which can cause poisoning if

inhaled. Therefore the concentration of gasoline vapor must be kept low, as

high concentrations of gasoline vapor can cause

Stimulation of the eyes, nose and

throat, nausea, headache, frustration and drunken physical discomfort. Extreme

concentrations of gasoline vapors can lead to rapid loss of consciousness.

In the treatment of

gasoline, it is necessary to maintain good ventilation, special attention to

the operation in a confined space to avoid the risk of inhalation of gasoline

vapor due to splashing.

Special

attention should be paid when cleaning and maintaining gasoline storage equipment.

Gasoline

can not be used as a detergent, and do not suck gasoline with mouth.

(17) General workshop tools and

equipment

It

is important that you always keep all your tools and equipment in good working

condition and that you are working correctly.

Remember

that tools or equipment should not be used in ways that are contrary to their

intended function. Equipment such as cranes, jacks, axles and chassis supports

or slings

shall not be subjected to loads

exceeding the maximum limit they can bear. Damage caused by overload does not

necessarily appear immediately, yet may cause serious accidents the next time.

Do not use tools or

equipment that has been damaged or is in poor working conditions, especially

some high-speed equipment such as grinding wheels. Damaged grinding wheel will

break without warning and cause serious injury.

Wear

appropriate eye protection when using grinding wheel, chisel or sand blasting

equipment.

Appropriate

breathing masks must be equipped when using sand-blasting equipment, handling

asbestos-containing materials, or using spray equipment.

There

must be ventilation device to control the amount of dust, mist and fumes in the

environment.

(18) Lubricants and greases

Avoid

long-term exposure to mineral oil, all the lubricating oil and grease, which

can irritate eyes and skin.

Health Protection Safety Code

-Wear

protective clothing, including impervious gloves.

-Do

not wear highly engine oil-contaminated clothing and footwear. Uniform must be

regularly cleaned and kept clean.

-Emergency

treatment of open wounds should be promptly available.

-During

working, try to apply the insulation cream on the skin, so as to avoid direct

skin contact with the engine oil.

-Remove

all engine oil by washing with soap and water. Apply a lanolin-containing

protective agent that will help replace the natural oils that are removed from

the skin.

If

skin lesions occur, go to hospitals immediately for medical assistance.

-Before

working, remove the residual grease on components as far as possible.

Goggles, such as

chemical goggles or face shields, should be worn if possible in direct contact

with the eyes; in addition, eye-wash equipment should be provided.

Environmental

precautions

Used waste engine oil

and oil filters should be recycled through authorized or licensed waste

disposal dealers or waste engine oil recyclers. If you have any questions, you

should promptly contact the relevant departments of the local competent

authorities for disposal.

It

is against the law to dump used engine oil directly into the ground, sewer or

drain or water pipes.

(19) noise

Extremely

decibel-level noise can occur while performing certain operations that can

cause hearing damage. At this time, proper hearing protection should be

equipped.

VII.

Vehicle certification

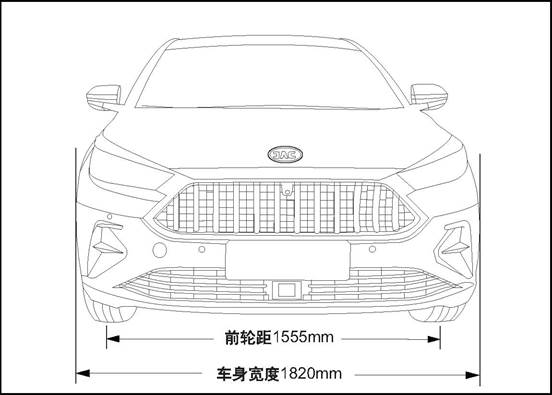

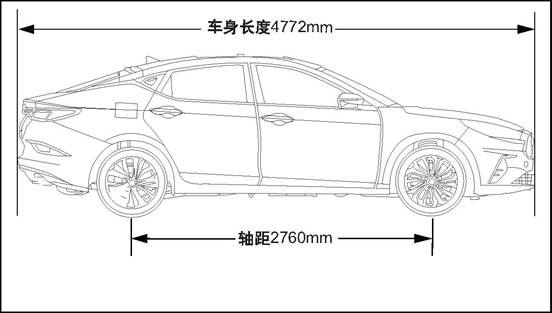

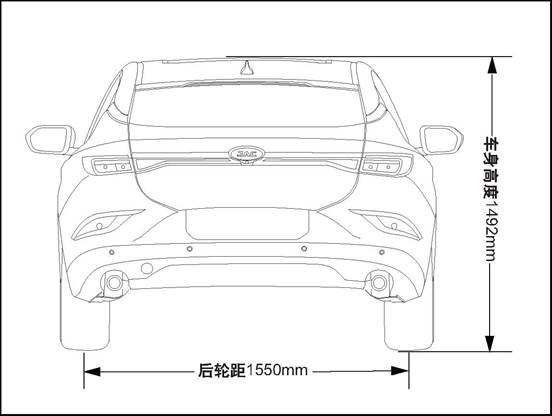

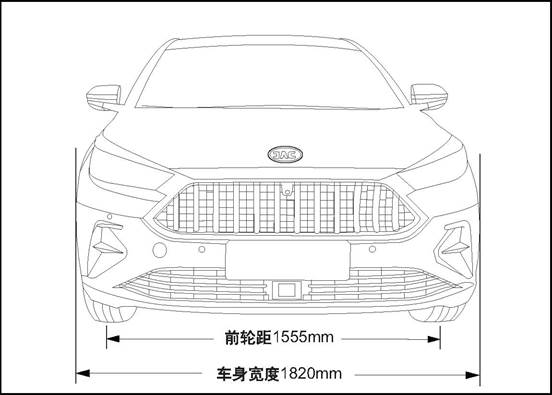

Front view

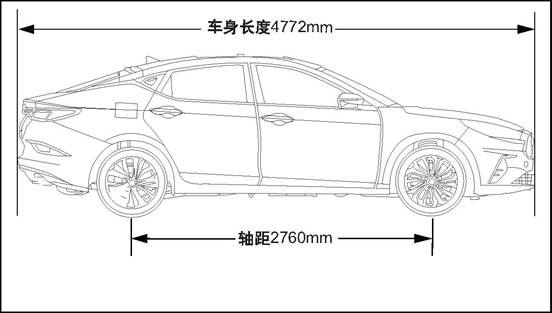

Side view

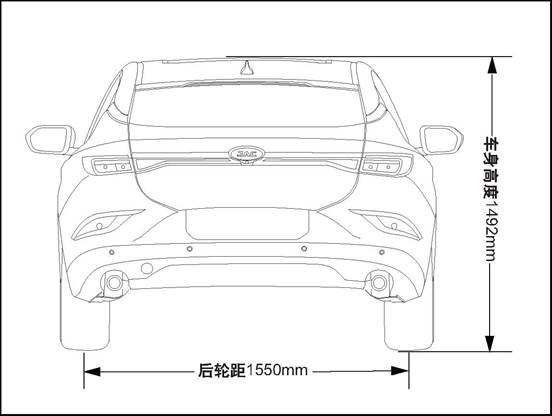

Rear view

(1) Vehicle dimensional

specifications

|

Item

|

Parameter

value

|

Unit

|

|

Total

length

|

4772

|

mm

|

|

Total

width

|

1820

|

mm

|

|

Total height

(empty load)

|

1492

|

mm

|

|

Wheelbase

|

2760

|

mm

|

|

Front

tread

|

1555

|

mm

|

|

Rear

tread

|

1550

|

mm

|

(2) Maintenance parameters 1-15

|

Item

|

1.5T+6MT

|

1.5T+CVT

|

Unit

|

|

passengers

|

5

|

5

|

Man

|

|

Curb weight

|

1432

|

1440

|

Kg

|

|

Maximum weight

|

1857

|

1865

|

Kg

|

|

Front axle’s load

|

967

|

977

|

Kg

|

|

Rear axle’s load

|

890

|

888

|

Kg

|

VIII.

vehicle identification

(1)

vehicle identification code

Vehicle

identification number

Vehicle

VIN is a legal identifier.

Vehicle

identification number (VIN) position

There

are several vehicle identification codes on the vehicle,and the following 10

are the most common:

1.

Located on the dashboard in the lower left corner of the windshield, VIN can be

seen through the windscreen.

2.

Under the front passenger seat.

3.

In the vehicle glove box.

4.

On the engine cover.

5.

On the front side of right-front door inner panel

6.

Lower side of left B-column

7.

On the front of the left front door inner plate

8.

On the upper side of tailgate inner panel

9.

Refer to ECU data.

10.Refer

to MP5 data.

(2) Label

Lable-vehicle certification

Lable-vehicle certification

IX.

noise, vibration and abnormal sound

(1)

diagnostic information and procedures

Wind noise / air sound

△CAUTION

When the technician checks the faulty location, the assistant

should drive the vehicle. Otherwise, it may cause injuries.

You

must test the car in the car, in order to accurately confirm the location of

the wind noise. In general, wind noise has major and minor leaks. If all leaks

are not repaired during the repair, wind noise can only be reduced and wind

noise can not be completely eliminated. Test-drive maintenance staff must bring

the following tools to help diagnose the specific location of wind noise:

Stethoscope

Masking

tape

Stitch

seam

Marker

pen

Follow the procedure below to try

the road:

Select

a line, with east, south, west and north four different directions of the

straight street.

Choose

less traffic or less noise in the street, to avoid affecting the test.

The road test is conducted at the

speed at which the customer believes the noise is most pronounced or noisy, and

a speed limit of more than the legal limit is strictly prohibited. The wind

noise emitted under the following conditions is external wind noise:

Wind

noise can be heard immediately while driving down the window glass.

When the tape is attached to the

various decorative seals and gaps, the wind noise disappears immediately.

Internal wind noise is caused by air escaping from the vehicle and should be

repaired as follows:

In

determining the location of the leak, attach the tape to the body lock pillar

relief valve. The air pressure will be formed immediately inside the car, and

the wind noise will be enhanced.

Use

a stethoscope to confirm the leak location.

Use

masking tape to temporarily repair leaks.

Continue

road test to confirm whether the wind noise is completely eliminated or other

leaked parts.

After

confirming all leaks by road test, return to the repair shop and make permanent

repairs with professional and reasonable positioning methods and sealing

materials.

Abnormal sound

Please

check the following table for common abnormal noise and solutions:

|

No.

|

Symptom

|

Parts for check

|

Solution

|

|

1

|

The vehicle

generates squeaky sound when the engine speed is high.

|

Check whether

insulation panel contacts vehicle’s bottom part

|

Lift the vehicle and perform a visual

inspection

|

|

Bend the insulation panel slightly to

create a gap between it and the bottom of the vehicle body.

|

|

2

|

The front of the vehicle squeaks when

the weather is cold

|

Check the balance

bar isolation rubber sleeve

|

Cold Road Test vehicle and pass the

bumpy road, so that the front suspension can reach maximum travel.

|

|

Remove the

isolation rubber sleeve and tape the front stabilizer bar, reinstall the

isolation rubber sleeve on the tape.

|

|

3

|

Bumpy rear bass issued by the boring

abnormal sound

|

Check if the spare tire in the luggage

compartment is properly secured

|

Open the luggage compartment and inspect

the spare tire and driver's tools.

|

|

Retighten spare tires and truck tools.

|

|

Test vehicle to check whether abnormal

sound has been eliminated.

|

|

4

|

The rear of the

vehicle emits a glass percussion while traveling on a bumpy road

|

Check the rear

door lock is not properly adjusted

|

Carry out road test to check this

situation.

|

|

Loosen the lock nut and adjust the lock.

|

|

5

|

The door squeaked

|

Check if the

harness connector inside the door trim panel creaks

|

Tap the trim plate and carefully observe

if you hear a squawk

|

|

Remove the door trim and wrap the foam

padding around the harness connector according to the actual vehicle

conditions.

|

|

6

|

Squeaking when

using the door

|

Check door hinges

for lack of lubrication.

|

Push the door back and forth and listen

carefully to check whether the door squeaks.

|

|

Use rust inhibitor to lubricate the door

hinge and apply grease.

|

(2)

maintenance guide

Wind

noise / air sound

External

wind noise

Repair

methods of wind noise leak and water leakage are very close. The actual repair

procedure depends on the type of sealing components being repaired.

Abnormal

sound

Repair of

abnormal sound

Abnormal

sound comes mainly from the relative motion that should not exist between the

vehicle parts. There are three ways to repair abnormal sound:

Firmly

tighten the parts so that there is no relative movement of the vehicle during

driving.

Separate

parts so that parts do not come into contact with them at work.

Isolate

parts so that there is no abnormal noise when parts move. A uniform surface

with low-friction can be used to eliminate sticking slip between parts.

X.

Tool purchasing channel and diagnosis device

If

you want to buy special tool, please contact 4S shop in each area of JAC. For

contact information, please contact 4008889933.

|

No.

|

Diagnosis device type

|

Diagnosis device version

|

Tool

No.

|

|

1

|

3G-X431

|

V11.70

|

JAC-T1Z002

|

Engine cover and wheel fender

Ⅰ. Overview

(1) Structure Outline

Components

location map

Engine

cover assembly

Engine

cover lock assembly

Engine

cover wire assembly

4.

Left fender assembly

5.

Engine bonnet stay bar

(2)

maintenance and technical parameters

|

Area

|

Engine cover and fender

|

Engine cover and fender

|

Engine cover and the front headlights

|

Engine cover and front bumper

|

|

Clearance

|

3.5±1.0mm

(S ≤ 1.0)

|

3.5±1.0mm

(P ≤ 1.0,S ≤ 1.0)

|

4.5±1.5mm

(P ≤ 1.5,S ≤ 1.5)

|

3.5±1.5mm

(P ≤ 1.0)

|

|

Flush

|

-1.0±1.0mm

(P ≤ 1.0,S ≤ 1.0)

|

-1.0±1.0mm

(P ≤ 1.0)

|

N/A

|

-1.0±1.5mm

(P ≤ 1.0)

|

|

Basis

|

Wheel

fender

|

Wheel

fender

|

|

Front bumper

|

(3) Torque parameter

|

No.

|

Project

|

Torque

(N·m)

|

|

1

|

Engine bonnet assembly and hinge fixing

bolt

|

25~29

|

|

2

|

Engine

cover lock fastening bolt

|

7~11

|

|

3

|

Engine bonnet open handle base fixing

screw

|

|

|

4

|

Engine bonnet hinge and vehicle body

fixing bolt

|

25~29

|

|

5

|

Wheel

fender fixing bolt

|

9~11

|

|

6

|

Engine

bonnet stay bar fixing bolt

|

7~11

|

(4)

Maintenance precautions

1.

Prevent damage or scratches when disassembling and installing components.

2.

When removing the clip from the trim, wrap the straight screwdriver’s head with

cloth.

3.

When installing body trims, make sure that the clips are securely installed in

the plate holes in the body, and carefully press them in.

4.

Two people are required to dismantle the larger parts to avoid dropping.

5.

Do not use excessive force when inserting or removing some rubber trims.

2. Engine cover assembly

(2) Disassembly

1.

The hood is opened and supported by one serviceman.

△Notice

When removing or installing cover device, you must adopt bearing alternately,

in order to avoid potential cause of vehicle damage or injuries.

2.

Mark the position of the hinge relative to the hood for positioning during

installation.

3.

Disassembly of engine cover assembly

1). Remove the two fixing bolts of engine bonnet and

hinge.

1). Remove the two fixing bolts of engine bonnet and

hinge.

△Note

Left and right side of engine cover share the same removing methods.

△Note

One person should lift the engine bonnet by hand to avoid contact with

peripheral parts.

2).

Take down engine cover from hinge.

△Notice Many people need to

cooperate to disassemble the engine compartment cover due to its enormous

weight. During disassembly, please mark hinge’s relative position on engine

hood so as to locate its position during assembly.

(3)

Installation

Assembly

engine cover assembly

1).

Install the engine bonnet into the installation position.

2). Remove the two fixing bolts of engine bonnet and

hinge.

2). Remove the two fixing bolts of engine bonnet and

hinge.

△

Notice Many people need to cooperate to disassemble the engine compartment

cover due to its enormous weight.

△Note Left and right side of

engine cover share the same removing methods. Tightening torque 25~29N·m

Close

the engine cover

3.

Engine cover lock assembly

(2) Disassembly

1.

Open engine cover and support it with rod

2.

Remove front bumper body assembly. See front bumper assembly

Disassemble

engine cover lock assembly

1) Take off the cable sheath 1 and

remove the cylinder pin 2 at the engine cover opening zipper end from the

engine cover lock.

1) Take off the cable sheath 1 and

remove the cylinder pin 2 at the engine cover opening zipper end from the

engine cover lock.

2). Install four fixing bolts of

engine cover lock.

2). Install four fixing bolts of

engine cover lock.

3).

Take down engine cover lock assembly.

(3)

Installation

Assembly

engine cover lock assembly

1). Install four fixing bolts of

engine cover lock.

1). Install four fixing bolts of

engine cover lock.

Tightening

torque 7~11N·m

2). Insert the cylinder pin 2 at the end of the open

cable into the middle position of the pulling pin seat from the opening of the

pre-installed drawing end of the lock body, rotate clockwise 90°, and then

insert the opening cable cable set 1 into the clamping slot of the drawing

fixing bracket.

2). Insert the cylinder pin 2 at the end of the open

cable into the middle position of the pulling pin seat from the opening of the

pre-installed drawing end of the lock body, rotate clockwise 90°, and then

insert the opening cable cable set 1 into the clamping slot of the drawing

fixing bracket.

2.

Install front bumper assembly

△Notice After the installation,

check the hood lock and check that the function is normal.

Harness and

engine cover lock is intact.

Close

the engine compartment cover

4. Engine bonnet open pull cable

(2) Disassembly

1.

Open engine cover and support it with rod

2.

Disassemble Front Wheel cover refer to front wheel cover

3.

Disassemble opening handle of engine cover

4.

Remove A column lower guard assembly See A column lower guard assembly

5.

Remove engine bonnet open pull cable

1). Disconnect the engine cover

lock wire drawing 1 and open the engine cover lock column.

1). Disconnect the engine cover

lock wire drawing 1 and open the engine cover lock column.

Take

pin 2 out from the bonnet lock.

2). Disconnect the engine cover lock wire drawing 2

and open the engine cover lock column.

2). Disconnect the engine cover lock wire drawing 2

and open the engine cover lock column.

3).

Remove the wheel cover wire buckle, take out the engine bonnet opening pull

wire.

(3)

Installation

1.

Install engine cover opening cable

1) Drive the end of the engine cover open cable handle

into the driver's cabin through the front coaming opening hole, insert the

rubber seal sheath into the front coaming installation hole from the front

side, and then connect the wire drawing buckle.

1) Drive the end of the engine cover open cable handle

into the driver's cabin through the front coaming opening hole, insert the

rubber seal sheath into the front coaming installation hole from the front

side, and then connect the wire drawing buckle.

2).

Connect the engine cover open handle base to open cable cylinder pin 1, and

clamp the cable cable sheath 2.

△Notice

pay attention to the position while connection, don't connect it wrong and keep

connection tight

3). Insert the cylinder pin 2 at the end of the open

cable into the middle position of the pulling pin seat from the opening of the

pre-installed drawing end of the lock body, rotate clockwise 90°, and then

insert the opening cable cable set 1 into the clamping slot of the drawing

fixing bracket.

3). Insert the cylinder pin 2 at the end of the open

cable into the middle position of the pulling pin seat from the opening of the

pre-installed drawing end of the lock body, rotate clockwise 90°, and then

insert the opening cable cable set 1 into the clamping slot of the drawing

fixing bracket.

2.

Install A column lower guard plate assembly

3.

Install opening handle of engine cover

4.

Install front wheel cover

Close

the engine compartment cover

△Note After the completion of

installation of engine cover lock wire drawing, for examination,

you have to

ensure that the engine cover lock control wire drawing and engine cover lock

assembly in good function and in good condition.

5. Opening handle of engine cover

(2)

Disassembly

1.

Disassemble opening handle of engine cover

1). Remove the opening handle of engine cover.

1). Remove the opening handle of engine cover.

(3) Installation

1. Install opening handle of engine cover

1. Install opening handle of engine cover

6. Engine bonnet stay bar

(2)

Disassembly

1.

Open the engine cover

△Note Remove and install the bonnet

strut. One maintenance worker opens and supports the bonnet strut. Another

removes the bonnet strut. Prevent hood from slipping off and causing injuries.

Disassemble

the engine cover supporting rod

1). Remove the 2 bolts that fix the bonnet pole to the

car body.

1). Remove the 2 bolts that fix the bonnet pole to the

car body.

2).

Take down the engine bonnet stay bar mounting bracket, and remove the engine

bonnet stay bar.

(3)

Installation

Install

the supporting rod of engine cover

1)

Install and protect the bonnet pole into the bonnet pole.

2).

Move the engine cover strut and mounting bracket to the mounting position.

△Note While closing, clamp the engine cover rod into the

snap joint of engine cover.

3). Install the 2 bolts to fix the

engine cover pole to the car body.

3). Install the 2 bolts to fix the

engine cover pole to the car body.

Tightening

torque 7~11N·m

Close

the engine cover

7. Engine

cover hinge assembly

(2) Disassembly

1.

Disassemble engine cover assembly see engine cover assembly

2.

Disassemble engine cover hinge

1). Remove the 2 bolts of the

bonnet hinge and body mounting.

1). Remove the 2 bolts of the

bonnet hinge and body mounting.

2).

Remove the engine cover hinge.

(3) Installation

1.

Install engine cover hinge

1).

Shift the engine bonnet hinge to the installation position.

2). Install the 2 bolts of the

engine cover hinge and body fixing.

2). Install the 2 bolts of the

engine cover hinge and body fixing.

Tightening torque 25~29N·m

2.

Install engine cover

(4) adjustment of the clearance and

side difference of engine cover

1.open

and support the engine cover

Adjust

the engine cover

Loosen

the fastening bolt between the engine cover and the hinge.

Adjust the engine hood

and watch it with fender and clearance around the headlight to ensure a

balanced interval between engine cover and headlight, fender, and that the

engine cover lock hook and lock body mesh in good condition.

Adjust

the clearance between the fender and hood, try to keep the engine cover and

fender of the seam in line with the requirements of 3.5mm.

△Notice

Move the engine cover on the left, right, front and backward to complete the

adjustment.

Close

the engine hood, examine the sealing situation.

Fasten

the engine cover hinge bolt.

Tightening torque 25~29N·m

6). According to the engine cover

face situation to adjust the engine cover buffer block to the appropriate

location, ensure the engine, the bartender bar and fender are without

interference in the process of closing.

Close

the engine cover.

VIII. Wheel fender

(1) Special tools

(None)

(2) Disassembly

open

and support the engine cover

2.

Disassemble left front doorsill guard panel assembly

3.

Disassemble front triangular cover board. Refer to “front triangular board”

4.

Disassemble Front Wheel cover refer to front wheel cover

5.

Remove front bumper body assembly. See front bumper assembly

6.

Remove the front bumper retaining bracket refer to the front bumper left

retaining bracket

7. Remove

the front combination lamp assembly. See front combination lamp assembly

8.

Disassemble the front side door assembly See left front side door assembly

9.

Remove the vent cover assembly See vent cover assembly

10.

Remove wheel fender

1). Remove the cover plate assembly of the lower wing.

1). Remove the cover plate assembly of the lower wing.

2).

Remove the 2 fixing bolts connecting the rear side of the wing panel to the

body.

3).

Remove the 4 fixing bolts connecting the front and lower side of the wing panel

to the body.

4).

Remove the 3 fixing bolts attached to the upper part of the wing plate and the

body.

5). Take down the fender.

5). Take down the fender.

(3) Installation

Install

wheel fender

1).

Move the wing plate to the installation position.

2).

Install the 3 fixing bolts attached to the upper part of the wing plate and the

body.

Tightening torque 9~11N·m

Tightening torque 9~11N·m

3)

install 4 fixing bolts connecting the front and lower sides of the wing panel

with the body.

Tightening torque 9~11N·m

Tightening torque 9~11N·m

4).

Install 2 fixing bolts connecting the rear side of the wing panel with the body.

Tightening torque 9~11N·m

Tightening torque 9~11N·m

5). Install wheel fender cover board assembly.

5). Install wheel fender cover board assembly.

2. Install

the vent cover assembly

3.

Install left front door assembly

4.

Install the front combination lamp assembly

5.

Install front bumper left fixing bracket

6.

Install front bumper assembly

7.

Install front wheel cover

8.

Install the front triangular cover plate

9.

Install the front sill guard plate assembly

10.

Close the engine compartment cover

△Notice

The left, right front wheel fender replacement step is the same.

△check

whether the fender has been assembled in position, and the clearance between fender

and vehicle body should be appropriate. If not, re-adjust or re-assemble the

fender.

Ⅸ.

Ventilation cover water retaining strip

(2) Disassembly

1.

Open the engine cover

2.

Disassemble ventilation cover water retaining strip

1) Remove the sealing strip slowly

by hand from one end of the strip until all the strips are removed.

1) Remove the sealing strip slowly

by hand from one end of the strip until all the strips are removed.

△Note:

Do not use force to pull the seal when removing.

(3)

Installation

1.

Disassemble ventilation cover water retaining strip

1)

Connect the rubber strip to the position along the end of the ventilation

cover.

△Notice the duct vent is partially

oriented toward the head.

△Notice the duct vent is partially

oriented toward the head.

2). Strike the sealing strip with a

rubber hammer and install it in place, and the adhesive strip has no wrinkle

and visibly loosens after being fastened.

△Notice When installing, use a

rubber hammer to strike the seal without too much force to prevent damage to

the seal.

Close the engine cover

X.

Engine cover sealing strip

(2) Disassembly

1.

Open the engine cover

2.

Disassemble engine cover sealing strip

1).

Remove the sealing strip buckle with the tool and remove the sealing strip.

(3)

Installation

1.

Install engine cover sealing strip

1). Attach the snaps on the seal to

the inner plate mounting holes and install the seals.

1). Attach the snaps on the seal to

the inner plate mounting holes and install the seals.

△Notice

When installing, pay attention to the alignment of the buckle with the hole to

prevent the buckle from being damaged.

Close

the engine cover

Front and rear bumpers

I. Overview

(1) Structure outline

Front

bumper assembly location map

1.

Front bumper assembly 2.

front grille assembly

Rear

bumper location map

1.

Rear bumper assembly

2.

Install rear anti-collision beam assembly

3.

Rear bumper right fixing bracket

4.

The left fixing bracket of rear bumper

(2) Torque parameter

|

sequence

|

Item

|

Torque

(N·m)

|

|

1

|

Front anti-collision beam assembly and

front end bracket fixing bolt

|

20~25

|

|

2

|

Rear anti-collision beam assembly and

vehicle body fixing screw

|

9~11

|

|

3

|

Front bumper and anti-collision beam

fixing bolt

|

|

|

4

|

front bumper and front wheel fender

fastening bolts

|

|

|

5

|

Connecting screws for front bumper to

front frame assembly

|

|

|

6

|

Connecting screw for front bumper to

guide plate

|

|

|

7

|

Front

anti-collision beam fixing bolt

|

|

|

8

|

The

cover plate on the front bumper is connected with the screws on the front

bumper

|

|

|

9

|

Rear bumper and body fixing screw

|

|

|

10

|

Rear bumper bracket and body fixing

screw

|

|

|

11

|

The front bumper fixing bracket and the

body and wing fixing screws

|

|

|

12

|

Front

grille fixing screw

|

|

(3) Maintenance

precautions

The

bumper is a resin material. Do not make it contact grease or other corrosive

chemicals . If you touch it accidentally, wash it with clean water immediately.

To

easily assemble and disassemble the bumper, the vehicle should be placed in the

lift machine, and ensure that the lift safety is locked.

When

dismantling the bumper, two people should be in operation, so as not to damage

the bumper in terms of falling on the ground.

When

the bumper is disassembled, the soft protective film is used to protect the

outer surface of the bumper so as not to be scratched.

Do

not force too much when dismantling the decoration, so as not to cause the

parts to deform and to be damaged.

6.

When assembling the rear bumper, snap it into place with the bumper fixing

bracket.

II. Front bumper assembly

(2) Disassembly

1.

Open the engine cover

2

Disconnect the negative port.of the battery

lift

the vehicle

4.

Disassemble front bumper assembly

1) Remove the 5 fixing screws 2

connected to the front bumper and the guide plate, and remove the 4 buckles 1

connected to the front bumper and the front wheel cover.

1) Remove the 5 fixing screws 2

connected to the front bumper and the guide plate, and remove the 4 buckles 1

connected to the front bumper and the front wheel cover.

2). Remove the 7 expansion buckles

2 connected to the front bumper assembly and the front skeleton Assembly,

2). Remove the 7 expansion buckles

2 connected to the front bumper assembly and the front skeleton Assembly,

Remove 4 screws 1 from the front

frame assembly.

3).

Remove 1 screw 2 and 2 buckles on the left and right side of the connection

between the front bumper and the wheel cover

1

1

4).

Remove the 2 fixing bolts connecting the middle part of the front bumper to the

plate mounting plate.

5). Gently remove the front bumper

to detangle the clamped relationship between the front bumper

5). Gently remove the front bumper

to detangle the clamped relationship between the front bumper

and the front bumper retaining

bracket.

6) disconnect the panoramic parking

front camera wire harness connector 1 and front anti-collision radar wire

harness connector 2 inside the front bumper.

6) disconnect the panoramic parking

front camera wire harness connector 1 and front anti-collision radar wire

harness connector 2 inside the front bumper.

(3)

Installation

1.

Install front bumper assembly

1). Move the front bumper to the installation

position and connect the panoramic parking front camera wire harness connector

1 and front anti-collision radar wire harness connector 2 inside the front

bumper.

1). Move the front bumper to the installation

position and connect the panoramic parking front camera wire harness connector

1 and front anti-collision radar wire harness connector 2 inside the front

bumper.

2). Insert the front bumper into

the front bumper fixing bracket.

2). Insert the front bumper into

the front bumper fixing bracket.

△Notice When the front bumper

assembly is assembled, it is put in place with the bumper fixed bracket card.

Connected

in place After installation, check whether there is a surface difference and

clearance

between

the bumper and the body fit.

3)

Install 2 fixing bolts connecting the middle part of the front bumper with the

front anti-collision beam.

Tightening

torque unconfirmed N·m

4). Remove 1 screw 2 and 2 buckles

on the left and right side of the connection between the front bumper and the

wheel cover

4). Remove 1 screw 2 and 2 buckles

on the left and right side of the connection between the front bumper and the

wheel cover

1

Tightening

torque unconfirmed N·m

5).

Remove the 7 expansion buckles 2 connected to the front bumper assembly and the

front skeleton Assembly,

4 pieces of screws.

4 pieces of screws.

Tightening

torque unconfirmed N·m

6). Install 5 fastening screws 2 in

the lower end of the front bumper assembly connected to the guide plate, and

install 4 buckles 1 in the front bumper connected to the front wheel cover.

6). Install 5 fastening screws 2 in

the lower end of the front bumper assembly connected to the guide plate, and

install 4 buckles 1 in the front bumper connected to the front wheel cover.

Tightening

torque unconfirmed N·m

2.

Place down the car.

3.

Connect the battery negative cable.

Close

the engine compartment cover

III.

Front anti-collision beam assembly

(2) Disassembly

1.

Open the engine cover

2

Disconnect the negative port.of the battery

3.

Remove front bumper body assembly. See front bumper assembly

4.

Remove the tweeter. See Tweeter

5.

Remove the woofer. See the woofer

6.

Disassemble the front anti-collision beam assembly

1) Disconnect the outdoor temperature

sensor wire harness connector 1, remove the outdoor temperature sensor,

disconnect the outdoor temperature sensor wire harness buckle 3, and separate

the wire harness. Remove 1 fixing bolt 2 in the middle of the front

anti-collision beam.

1) Disconnect the outdoor temperature

sensor wire harness connector 1, remove the outdoor temperature sensor,

disconnect the outdoor temperature sensor wire harness buckle 3, and separate

the wire harness. Remove 1 fixing bolt 2 in the middle of the front

anti-collision beam.

2).Remove

the left and right 4 fixing bolts of front anti-collision beam assembly and

vehicle body girder.

Remove 1 fixing bolt 2 for each left and right

connecting the front collision beam assembly to the front module.

Remove 1 fixing bolt 2 for each left and right

connecting the front collision beam assembly to the front module.

3).

Take down the front anti-collision beam assembly.

(3)

Installation

1.

Install the front anti-collision beam assembly

1).

Align the front anti-collision beam assembly to the installation position.

2).

Install the left and right 4 fixing bolts of front anti-collision beam assembly

and vehicle body girder.

Install 1 fixing bolt 2 for each left and right

connecting the front collision beam assembly to the front module.

Install 1 fixing bolt 2 for each left and right

connecting the front collision beam assembly to the front module.

Tighten

torque 20~25N·m

3). Connect the outdoor temperature sensor wire

harness connector 1, install the outdoor temperature sensor, and connect the

outdoor temperature sensor wire harness buckle 3. 1 fixing bolt 2 in the middle

of the anti-collision beam before installation.

3). Connect the outdoor temperature sensor wire

harness connector 1, install the outdoor temperature sensor, and connect the

outdoor temperature sensor wire harness buckle 3. 1 fixing bolt 2 in the middle