1.

warning and precautions

(1)

warning and precautions

Definition

of "Warning", "Important Note" and "Attention”

The

diagnostic and maintenance procedures in this manual include general and specific

"warnings", "important notices" and "cautions",

and JAC is committed to providing maintenance information to assist the

after-sales service technician in the diagnosis and maintenance system , so

that the vehicle can run normally, but if the technician does not operate as

recommended, some programs may pose a risk to the technician.

"WARNING",

"IMPORTANT NOTES" and "CAUTION" are prepared to prevent the

occurrence of such hazards, but not all hazards are predictable. This

information is displayed in prominent positions in the maintenance manual. This

information is prepared to prevent the following:

·Causing

serious injury to people

·Vehicle

damage

·Unnecessary

vehicle maintenance

·Unnecessary

parts replacement

Improper

repair or replacement of vehicle parts

The definition of

"Warning"

When

you encounter a "warning", it asks you to take the necessary action

or to prohibit the action taken. If you ignore "warning", you may

have the following consequences:

·Causing

serious injury to people

If

the vehicle is improperly repaired, it will cause serious personal injury to

the driver and / or passenger of the vehicle.

The definition of

"important note"

"Important

note" requires special attention to the measures necessary or prohibited.

If you ignore the "important note", it will lead to the following

consequences:

·Vehicle

damage

·Unnecessary

vehicle maintenance

·Unnecessary

parts replacement

·Abnormal

operation or performance of the system or component being repaired

·Damage

related systems or components

·Damage

fasteners, basic tools or special tools

·Engine

coolant, lubricating oil or other essential liquid leakage

The definition of

"Attention”

The

"attention" statement emphasizes the necessity of a diagnostic or

maintenance procedure, and the purpose of the "attention" statement

is as follows:

Clear

procedure

Provide

supplementary information for completing a program

Clarify

the reason for an operation according to the recommended procedure

Provide

information that helps to complete the program in a more efficient way

Provide

the technician with past experience information to make the process easier

Warning about vehicle

lift

△Warning To avoid vehicle damage,

serious personal injury or even death, when the main part is removed from the vehicle

and the vehicle is supported by an elevator, please use jack to support the

corresponding vehicle parts to be dismantled..

Warning on handling

anti-lock braking system components

△Warning Some parts of the

anti-lock braking system (ABS) can not be serviced separately. Attempting to

disassemble or disconnect certain system components can result in personal

injury and / or malfunction of the system. Only repair those parts that are

permitted to be removed and installed.

Warning about crash

repair permission devices

△ Warning To avoid personal

injury when exposed to toxic flamings generated from wipes or electroplating

(zinc oxide) metal during grinding / cutting of any type of metal or sheet

molding, the working process must be operated in a well-ventilated area and

technician should equip permitted respirators, goggles, earplugs, welders

gloves and protective clothing.

Warning about helper

driving

△

Warning When the technician checks the defective parts, the vehicle should be

driven by the assistant. Otherwise, it may cause personal injury.

Warning about

disconnecting the battery

△

WARNING Before servicing any electrical parts, the ignition key must be in the

OFF or LOCK position and all electrical loads must be "OFF"

),

Unless otherwise stated in the operating procedure. If the tool or equipment is

easily accessible to the exposed live electrical terminals, disconnect the

battery negative cable. Violation of these safety instructions may result in

personal injury and / or damage to vehicles, vehicle parts.

△

Warning If you repair the airbag, you must disconnect the battery negative at

least 90s in order to carry out other operations.

Warning about brake

dust

When

servicing wheel brake parts, avoid the following:

Do

not wear a brake friction lining.

Do

not use sandpaper to grind brake friction linings.

Do

not use a dry brush or compressed air to clean the wheel brake parts.

△ Warning Some models or aftersales

installation brake parts may contain fibers, which may be mixed in dust.

Inhalation of dust containing fibers can cause serious damage to the body.

Clean any dust on the brake parts with a damp cloth.

Warning about brake

fluid

△ WARNING Braking fluid is easy to

absorb moisture and absorb moisture. Do not use brake fluid that may be

contaminated with water in open containers. Use of inappropriate or

contaminated brake fluid may cause system malfunction, vehicle malfunction, and

personal injury.

A warning about the

irritation of the brake fluid

Brake

fluid is irritating to skin and eyes. Once the contact should take the

following measures:

Eye

contact - rinse thoroughly with water

Skin

contact - Wash with soap and water

Warnings about brake

tube replacement

△ WARNING Be sure to use the

correct fasteners when replacing the brake tube. Otherwise, it may cause damage

to the brake tube and brake system. The damage may cause personal injury.

Warning about clutch

dust

△

WARNING Do not use a dry brush or compressed air to clean the parts when

grinding the clutch parts, or grinding them with sandpaper.

All

operations mentioned above will generate dust Use a damp cloth (but not

soaked). The clutch plate may contain fibers, and if the dust is generated

during the repair process, the fibers are mixed into the air. Inhalation of

dust containing fibers can cause serious damage to the body.

Warning about

collision cut

△

Warning please cut the recommended parts only, otherwise it will damage the

integrity of the vehicle structure, and may cause personal injury in the event

of vehicle collision.

Warning about eye

protection

△WARNING

In the course of this procedure, licensed goggles and gloves should be worn to

reduce the risk of personal injury.

Warning about moving

parts and hot surfaces

△

WARNING When working around the running engine, avoid contact with moving parts

and hot surfaces to prevent personal injury.

Warning about goggles

and gloves

△ WARNING Do not wear goggles and

gloves when removing exhaust system parts, otherwise rusting and sharp edges

from worn parts of the exhaust system can cause serious personal injury.

Warning about removal

of tank cover

△ WARNING To avoid being burned, do

not remove the tank cover until the engine is cooled. If the tank and the

radiator are not cooled, remove the tank cover, the cooling system will release

hot high pressure liquid and steam.

Warning about cooling

system maintenance

△

Warning As long as there is pressure in the cooling system, even if the

solution in the radiator does not boil, the solution temperature will be much

higher than the boiling temperature. .

If the tank

cover is opened when the engine is not cooled and the pressure is still high,

the engine coolant will immediately boil and may be sprayed onto the operator

and cause severe burns when performing maintenance on the cooling system.

Warning about road

test

△WARNING Please test vehicle with

your safety guaranteed and follow traffic regulations. Do not attempt any

operation that may endanger vehicle control. Violation of these safety

instructions may result in serious personal injury and vehicle damage.

Warning

about goggles and fuel

△

Warning When processing fuel, be sure to equip goggles to prevent oil from

splashing into the eyes.

Braking system is an

important note for filling brake fluid

△ Important note: When adding brake

fluid to the brake master cylinder, use only the brake fluid in the clean,

sealed brake fluid container, and meet the DOT4. Failure to use the recommended

brake fluid can cause contamination, thereby damaging the rubber seals and / or

rubber liners inside the hydraulic brake system components.

Important note of

brake clamps

△

Important note: When removing the brake caliper, use a wire hanging brake

caliper, so as not to damage the brake tube.

Special precautions

for the effects of brake fluid on paint and electrical components

△

IMPORTANT NOTE: Avoid damaging the brake fluid onto the paint, electrical

connectors, wires or cables. The brake fluid can damage the paint and cause

corrosion of the electrical components.If

the

brake fluid contacts the electrical connector, wire or cable, wipe the brake

fluid with a clean cloth.

Important

note of Fasteners

△

IMPORTANT NOTE: Please use the correct fastener in the correct position.

Replace the part number of the fastener must be correct, need to replace the

fastener or need to use

Thread

locking glue or sealant fasteners are specified in the maintenance procedure,

and no paint, lubricating oil or corrosion inhibitor may be used on the

fastener or fastener connection surface unless otherwise stated.

These

coatings affect the torque and clamping forces of the fasteners and damage the

fasteners. When assembling fasteners, be sure to use the correct fastening

sequence and tightening torque to avoid damage to parts and systems.

Important

precautions of not twisting or bending when installing the hose

△

IMPORTANT NOTE: The inlet and outlet hoses may not be twisted during

Installation and may not bend or deform the hose for ease of Installation, as

this may cause parts damage.

Parts

are damaged.

Significant

precautions for machined surface damage

△

Important Note: Do not scratch, scratch or damage the sealing surface, the

sealing surface is machining surface, machine surface damage will lead to

leakage.

The

important precautions for the removal of the ring gear

△

IMPORTANT NOTE: Do not pry the ring gear from the differential housing and pry

the gear ring from the differential housing to damage the ring gear and / or

the differential case.

Important note of

sealant

△

Important Note: Do not let room temperature hardening sealant into the threaded

blind hole, if the room temperature hardening sealant into the threaded blind

hole, the fastener in the fastening

Will

have a hydraulic locking effect, the fastening of the fasteners will cause the

fasteners and / or other parts to be damaged, and also make the fastener in the

fastening can not get the correct clamping force, the wrong clamping force Will

make the parts can not get the correct seal, resulting in leakage, fasteners

can not be properly tightened, will make parts loose or separate, resulting in

serious damage to the engine.

Important

considerations when steering wheel in the steering limit position

△

Important note: The steering wheel in the steering limit position of the

duration of not more than 5s, otherwise it may damage the steering motor.

2. vehicle inspection

(1) projects

should be checked when operating the vehicle

Tires, vehicles and

positioning operations

Pay attention to the vibration of

steering wheel or seat when the car travel at normal speed, which indicates

that there is a need for a balance within one of wheels.In addition, the

deviation on the straight road shows that it may be necessary to adjust the

tire pressure or wheel positioning.

Operation of the

steering system

Be

wary of changes in steering action, when the steering wheel rotation difficult

or free travel is too large, or when turning or parking abnormal sound, it

needs to do inspection.

(2)

project should be checked at least once a month

Tires, wheels and air

pressure check

Check the tire is abnormal wear or

damage, but also check the wheel is damaged, check the tire cold state

pressure, but also check the spare tire, keep the recommended pressure on the

tire label.

Oil leak check

After the vehicle has been parked

for a period of time, please check regularly whether water, engine oil, fuel or

other fluid exist under the vehicle. Water-dripping is a normal phenomenon when

the air conditioning system is used . if fuel leak or smoking is detected,

please check reasons and eliminate fault timely.

(3)

Check the project at least twice a year

Brake master cylinder

tank level

Check the oil and keep it at the

correct level. The liquid level may indicate that the brake pads of the disc

brakes are worn and require maintenance, check the vent holes on the tank cover

to ensure no dirt and airway clear

Clutch pedal free

stroke

Check

the clutch pedal free travel, adjust if necessary. See clutch pedal free travel

adjustment.

Door and window seal

lubrication

Apply

a layer of silicone grease to the seal with a clean cloth.

3. lift the vehicle

(1) to lift the vehicle

Refer

to drive shaft "Warnings about vehicle lift" in the "Warnings

and Precautions".

To

avoid personal injury, be sure to use the jack when you are working on a

vehicle that is only jack-mounted or under a vehicle.

Vehicle lift point

△

Caution: the rear lift block can not hit the sill plate to the outside of the

frame rails or the floor.

Place

the rear lift block in the following locations: Beneath the junction between

the rear frame rail and side frame rail.

△

Caution: the rear lift block can not hit the sill plate to the outside of the

frame rails or the floor.

Place

the front lift block in the following location:

Beneath

the junction between the front frame rail and side frame rail.

IV. maintenance

(1) specifications

Fuel economy

indicators index

|

Fuel

consumption

|

unit

|

Parameters

|

|

1.5T+6MT

|

L/100km

|

|

|

1.5T+CVT

|

L/100km

|

7.5L

|

(2)Front and rear wheel positioning

parameters (no load)

|

Item

|

Positioning

parameters

|

Parameters

value

|

|

Wheel run out

|

Radial

direction

|

>0.3mm

|

|

Axial

Direction

|

>0.3mm

|

|

Wheel balancing

|

Dynamic imbalance (unilateral) / g

|

≤15

|

|

Dynamic imbalance (sum) / g

|

≤25

|

|

Four-wheel

positioning parameters

|

Front

wheel

|

Front wheel camber

|

15′±30′

|

|

Kingpin caster angle

|

5°19′±30'

|

|

Kingpin caster angle

|

12°99′±30′

|

|

The front wheel toe-in (unilateral)

|

5′±2.5′

|

|

Rear

wheel

|

The rear wheel toe-in (unilateral)

|

4′±5′

|

|

Rear wheel total toe-in

|

8′±10′

|

|

Rear camber

|

-1°10′±30′

|

(3)

Wheel, tire size and cold inflation pressure

|

Item

|

Positioning parameters

|

Parameters

value

|

|

Standard tire

|

Specification

|

215/50R17 95V

|

225/45R18 95V

|

|

Front tire pressure/kPa

|

230

|

230

|

|

Rear tire pressure/kPa

|

230

|

230

|

|

Inflated pressure under cold-state/kPa

|

230±10

|

230±10

|

|

Spare

tire

|

Specification

|

T135/80R17

|

T135/80R17

|

|

Tire pressure/kPa

|

420

|

420

|

Regular

Maintenance Instructions

The

normal use of the vehicle

The

maintenance items given in the maintenance plan has assumed that the vehicle is

used for the following purposes:

Passengers

and cargo are transported under the constraints indicated by the tire label at

the driver's door edge.

Drive

on the proper road surface and within the legal limits.

1. Indicator arrows

1. Indicator arrows

Move

direction arrow

Rotation

direction arrow

Part

number label

Partial

magnification

(2) acid and alkali

For

example, corrosive sodium carbonate, sulfuric acid.

Used

for battery and other materials’ cleaning.

Irritation

or erosion for the eyes, skin, smell and throat, and will cause burns to the

human body and damage to ordinary protective clothing.

Avoid

splashing on eyes, skin and clothing. Wear proper protective clothing, gloves

and goggles to prevent inhalation.

Be

sure to include flushing equipment nearby, such as eye wash bottles, shower

pads, soap, etc., for immediate relief in the event of splashes.

Marked

signs of eye danger in a prominent position.

(3) Brake fluid

If the splashed skin and eyes will

be a little irritated, as far as possible to avoid direct contact with the

brake fluid and the eyes of the skin, inhaling brake fluid at room temperature,

the risk of steam is not high, because of its very low vapor pressure.

(4) Chemical materials

Chemical

materials such as solvents, sealants, adhesives, coatings, resin foams, battery

acid, engine coolant, brake fluids, fuels, lubricants and greases should be

used very much note. They can be poisonous, harmful, aggressive, irritating or

highly flammable, with highly dangerous odors and dusts.

The effects of long-term

overexposure to a chemical environment may be immediate or chronic, transient

or permanent, cumulative, superficial, life-threatening or may affect lifespan.

Chemical Materials -

What to do

Carefully read and follow the

warnings and cautions on the container of origin and any accompanying flyers,

posters or other instructions for use, as well as the health and safety

information sheets for the ingredients, which are obtainable by the

manufacturer.

After

getting physical contact with chemical materials, remove it from the skin and

clothing as soon as possible, and immediately replace the heavily immersed

clothing and thoroughly clean it.

Strictly

follow the work instructions and wear protective clothing to avoid direct

contact with the skin and eyes.

It

must be cleaned before handling breaks, eating, smoking, or using the washroom

while handling chemical materials.

Keep

working areas clean, tidy and do not spill chemicals.

Chemical Materials -

Actions to be avoided

Unless specified by the

manufacturer, chemical materials can not be mixed at will; some chemicals can

form other toxic or harmful chemicals that can release other toxic and harmful

gases when mixed and can cause explosions and other accidents.

Do

not spray chemical materials in a closed environment.

Unless instructed by the

manufacturer, chemical materials should not be heated as some chemicals are

highly flammable while others may emit toxic and noxious gases.

Do not allow the chemical container

to remain open and the emitted gas may accumulate to a toxic, hazardous or

explosive level. Some gases are heavier than air and accumulate in confined

spaces.

Chemicals

can not be loaded into unlabeled containers.

Do not use chemicals to clean hands

and clothing. Chemicals, especially solvents and fuels, can dry the skin, cause

allergies, inflammation of the skin or affect your health by being directly

absorbed through the skin.

Unless

the container has been cleaned under supervision, otherwise do not use empty

containers for storing other chemical materials.

Do

not smell chemical materials at will Short-term exposure to high concentrations

of gas may still lead to poisoning or injury

(5) Dust

Powder, dust, and dust may be

irritating, harmful or toxic. Avoid inhalation of powdered chemicals and dust

raised by dry rubbing operations. Wear respiratory mask guards to prevent

inhalation of dust if ventilation is poor.

Fine

dust of combustible material may cause the danger of explosion and avoid

explosion and sources of ignition.

(6) Electric shock

Failure

to use the electrical equipment incorrectly or abuse the equipment in good

condition may result in electric shock.

Be

sure to maintain the electrical equipment within the specified time and regular

testing. Faulty equipment should be marked and preferably moved outside the

work area.

Do

not expose the wires, cables, plugs and jacks to wear, kinks, cuts, cracks, or

other damage. Do not allow electrical equipment and wires to contact with

water.

Ensure

that the electrical equipment is protected by the correct fuse.

Misuse

of electrical equipment is prohibited, and do not not use any device with

hidden trouble, because the result may affect personal safety.

Ensure

that the cable for mobile electrical equipment will not be pinched and damaged.

Basic

first-aid training must be performed on specialized electrical operators.

In

the event of an electric shock:

Turn

off the power before touching the victim.

If

you can not turn off the power, use dry insulator material to remove the

victim's power.

If

you have specialized emergency training, carry out on-site first aid

immediately.

Request

medical assistance.

(7) Exhaust

Exhaust gas contains toxic and harmful

chemicals such as carbon oxides, nitrogen oxides, acetaldehyde, lead and

aromatic hydrocarbons. The engine can only be operated with suitable exhaust

ventilation or general ventilation and with open space.

(8) Fiber isolation

Used

to isolate noise and sound.

The

fibrous surface with sharp edges can cause skin irritation.

During

operation, the instructions of the operating procedures and gloves should be

worn to avoid excessive skin contact with the fibers.

(9)Fire

Many

materials related to vehicle maintenance are extremely flammable. Some

materials are toxic and harmful when they are burned.

Please

follow fire safety practices when storing and disposing flammable materials or

solvents, especially near electrical equipment or near welding areas.

Before

using electrical and welding equipment, please make sure that there is no risk

of fire

When

welding or using heating equipment, prepare a fire extinguisher around the work

area.

(10) First aid

Not

only to comply with the law, but also first aid trained personnel should be in

the workplace.

If

eyes are splashed, rinse with water for at least 10 minutes.

If

the skin is contaminated, wash the contaminated area with soap and water.

If

frostbite, the area affected by frostbite is immersed in ice or cold water.

Inhalation

of toxic gases should be promptly transferred to fresh air. If adverse

reactions persist, they should be taken to the hospital for medical attention

immediately.

If

you inadvertently mistakenly suck the liquid, you should inform the physician of

the information marked on the container or label, unless the instructions on

the label, or not blindly guide.

(11) Foam - polyurethane

Cured

foam is a cushion for seating and decoration.

Follow

the manufacturer's instructions.

Components

that haven’t been chemically effected are irritating and may be harmful to the

skin and eyes. Wear gloves and goggles during operation.

Persons

with chronic respiratory diseases, asthma, bronchial problems, or those with

genetic allergies should not handle or approach uncured material.

Their

spare parts, vapors or sprays will cause immediate irritation and allergic

reactions and can be toxic and harmful.

Remember

not to breathe vapor or spray, these materials must be used in a

well-ventilated and breathable protected. Do not remove the mask immediately

after spraying.

Wait

for vapor to completely dissipate before removing.

The uncured components

and the matured foam are burned to produce toxic and harmful gases. During the

foam operation, unless the vapor or spray has been completely removed, no

smoking, no open flame, no electrical equipment, no foam, or special thermal

cutting of foams should be done in a well-ventilated environment.

(12) Fuel

Minimize

direct skin contact with the fuel, if exposed to fuel, immediately wash with

soap and water directly on the fuel skin.

Gasoline

Extremely

flammable - follow no-smoking regulations.

Accidental

swallowing can cause mouth and throat irritation, and stomach absorption can

lead to generalized weakness and confusion. A small amount of gasoline can

affect a child's life and safety.

Therefore, it is very dangerous if

the liquid enters lungs.

Gasoline

will cause dry skin. Long-time or frequent contact will cause skin allergies

and dermatitis. The fuel can cause severe pain if entering into eyes.

Motor

gasoline may contain a large amount of benzene, which can cause poisoning if

inhaled. Therefore the concentration of gasoline vapor must be kept low, as

high concentrations of gasoline vapor can cause

Stimulation of the eyes, nose and

throat, nausea, headache, frustration and drunken physical discomfort. Extreme

concentrations of gasoline vapors can lead to rapid loss of consciousness.

In the treatment of gasoline, it is

necessary to maintain good ventilation, special attention to the operation in a

confined space to avoid the risk of inhalation of gasoline vapor due to

splashing.

Special

attention should be paid when cleaning and maintaining gasoline storage

equipment. Gasoline can not be used as a detergent, and do not suck gasoline

with mouth.

(13) gas cylinder

Gases such as oxygen, acetylene,

argon and propane are usually stored in gas cylinders at a pressure of 13.8 Mp

(2001 psi). Special care must be taken when handling these cylinders. Avoid

handling the cylinders or valves mechanically Sexual damage. The gas filled in

the cylinder should be given clearly and appropriately.

Cylinders should be stored in a

well-ventilated area and protected from direct sunlight in the snow or in the

sun. Fuel gases, such as acetylene and propane, should not be stored with

oxygen cylinders.

Pay

special attention and prevent the leakage of gas cylinders and piping and avoid

sources of ignition.

Only

professionally trained personnel may work on gas cylinders.

(14) General workshop tools and

equipment

It

is important that you always keep all your tools and equipment in good working

order and that you are working correctly.

Remember

that tools or equipment should not be used in ways that are contrary to their

intended function. Equipment such as cranes, jacks, axles and chassis supports

or slings

shall

not be subjected to loads exceeding the maximum limit they can bear. Damage

caused by overload does not necessarily appear immediately, yet may cause

serious accidents the next time.

/

Do not use tools or equipment that

has been damaged or is in poor working conditions, especially some high-speed

equipment such as grinding wheels. Damaged grinding wheel will break without

warning and cause serious injury.

Wear

appropriate eye protection when using grinding wheel, chisel or sand blasting

equipment.

Appropriate

breathing masks must be equipped when using sand-blasting equipment, handling

asbestos-containing materials, or using spray equipment.

There

must be ventilation device to control the amount of dust, mist and fumes in the

environment.

(15) Lubricants and greases

Avoid

long-term exposure to mineral oil, all the lubricating oil and grease, are eye

and skin irritation.

Health Protection

Safety Code

Long-term

and repeated contact with the engine oil should be avoided, especially the

engine oil that has been used.

-Wear

protective clothing, including impervious gloves.

Do

not put a damp cloth with engine oil in your pocket.

Avoid

engine oil contamination of clothing, especially intimate clothing.

-Do

not wear highly engine oil-contaminated clothing and footwear. Uniform must be

regularly cleaned and kept clean.

-Emergency

treatment of open wounds should be promptly available.

-During

working, try to apply the insulation cream on the skin, so as to avoid direct

skin contact with the engine oil.

-Remove

all engine oil by washing with soap and water. Apply a lanolin-containing

protective agent that will help replace the natural oils that are removed from

the skin.

If

skin lesions occur, go to hospitals immediately for medical assistance.

-Before

working, remove the residual grease on components as far as possible.

Goggles, such as chemical goggles

or face shields, should be worn if possible in direct contact with the eyes; in

addition, eye-wash equipment should be provided.

Environmental

precautions

Used waste engine oil and oil

filters should be recycled through authorized or licensed waste disposal

dealers or waste engine oil recyclers. If you have any questions, you should

promptly contact the relevant departments of the local competent authorities

for disposal.

It

is against the law to dump used used engine oil directly into the ground, sewer

or drain, or into water pipes.

(16) noise

Extremely

decibel-level noise can occur while performing certain operations that can

cause hearing damage. At this time, proper hearing protection should be

equipped.

VII. fasteners specifications

(1) Fastener specifications

JAC Automotive

Engineering Standards have adopted a portion of the standard ISO metric metric

fastener dimensions to reduce the number of fastener sizes used while

maintaining the best thread quality for each thread size.

(2) Main fastener tighten torque

table

|

No.

|

Name

|

Fastening

torque(N·m)

|

|

1

|

Clutch

pull cable bracket fixing bolt

|

18~22

|

|

2

|

Clutch

main cylinder and oil inlet pipe assembly

|

18~22

|

|

3

|

Main

cylinder oil outlet hard pipe assembly

|

20~28

|

|

4

|

The

clutch pedal and the main clutch pump and intake pipe installation

|

20~28

|

|

5

|

Clutch

pedal fixing bolt

|

20~28

|

|

6

|

Clutch

pressure plate mounting bolt

|

20~28

|

|

7

|

Main

cylinder oil outlet hard pipe assembly

|

18~22

|

|

8

|

Steering

gear and front sub frame connection bolts

|

95~105

|

|

9

|

Front

stabilizer bar fixing bracket

|

55~65

|

|

10

|

Remove

the fixed bolt between subframe and front body.

|

190~210

|

|

11

|

Tightening

bolt between steering tie rod and steering knuckle.

|

40~50

|

|

12

|

Transmission

universal joint bolt

|

30~35

|

|

13

|

Rear

fixed bolt of front subframe

|

3~5

|

|

14

|

Front

shock absorber installing nuts

|

45~55

|

|

15

|

Remove

the 3 fixing nuts of front shock absorber and vehicle body.

|

45~55

|

|

16

|

The

connecting bolt between front shock absorber and steering knuckle

|

130~150

|

|

17

|

Remove

the connecting nut of front transverse stabilizer bar and front shock

absorber assembly.

|

65~75

|

|

18

|

Remove

fixing bolts between the lower swing arm and the sub frame front connecting

point.

|

150-170

|

|

19

|

Tighten

the fixing bolt of lower swing arm and sub-frame rear connection point.

|

190~210

|

|

20

|

Tighten

1 fixing nut that connects the lower swing arm ball pin and the steering

knuckle.

|

80~90

|

|

21

|

Disassembly

Stabilizer Lever connecting ball head and front column assembly retaining

nut.

|

65~75

|

|

22

|

Front

sub-frame connecting bracket

|

190~210

|

|

23

|

Front

accessory frame and body connection tightening

|

55~65

|

|

24

|

Steering

rod and steering knuckle connected slotted nut

|

40~50

|

|

25

|

Fixing

bolt of front wheel speed sensor assembly and front steering knuckle

|

8~12

|

|

26

|

Front

brake caliper and knuckle connecting bolts

|

7~11

|

|

27

|

stabilizer

fixing bracket 2 fixing bolts.

|

55~65

|

|

28

|

Front

fixed bolt of front subframe

|

170~190

|

|

29

|

Sub

frame rear fixing bolts

|

170~190

|

|

30

|

rear

shock absorber and body connection nut.

|

45~55

|

|

31

|

Rear

shock absorber and rear guide arm connecting bolts

|

120~140

|

|

32

|

Rear

suspension-arm assembly and rear stabilizer rod connecting bolt

|

65~75

|

|

33

|

Rear

vertical arm and vertical body-connecting bracket connecting bolt

|

100~120

|

|

34

|

Rear

suspension-arm assembly and sub-frame connecting bolt

|

100~120

|

|

35

|

The

connecting bolt between lower suspension arm ball pin and steering knuckle

|

130~150

|

|

36

|

The

connecting bolt between lower suspension arm ball pin and steering knuckle

|

100~120

|

|

37

|

The

connecting bolt between lower suspension arm ball pin and steering knuckle

|

100~120

|

|

38

|

The

connecting bolt between upper rod and rear sub-frame

|

100~120

|

|

39

|

The

connecting bolt between upper rod and rear steering knuckle

|

150-170

|

|

40

|

The

connecting bolt between lower rod and rear sub-frame

|

100~120

|

|

41

|

The

connecting bolt between lower rod and rear steering knuckle

|

100~120

|

|

42

|

Rear

brake and rear hub connecting bolts

|

7~11

|

|

43

|

Connecting

bolt of rear wheel hub and rear steering knuckle assembly

|

90~110

|

|

44

|

Connecting

nut of rear horizontal stabilizer and rear stabilizer rod

|

65~75

|

|

45

|

Rear

wheel speed sensor fixing bolts

|

8~12

|

|

46

|

tightening

nut of tie rod’s end

|

40~50

|

|

47

|

wheel

nut

|

100~120

|

|

48

|

Bolts

and nuts of front shock absorber to steering knuckle

|

130~150

|

|

49

|

self-lock

nut between drive shaft to front wheel hub assembly.

|

290~310

|

|

50

|

Tightening

nut of steering rod and steering knuckle

|

40~50

|

|

51

|

Tightening

nut of lower swing arm ball pin and the steering knuckle.

|

80~90

|

|

52

|

Fixing

bolts of wheel speed sensor

|

8~12

|

|

53

|

tightening

nut of tie rod’s end

|

40~50

|

|

54

|

Fixing

nut of brake limit switch

|

8~10

|

|

55

|

connecting

nut of brake pedal and brake vacuum booster.

|

20~25

|

|

56

|

Fixing

bolt of brake pedal and body fixing bolt.

|

20~25

|

|

57

|

The

connecting bolt of front brake caliper and steering knuckle

|

75~85

|

|

58

|

Connecting

bolt of front brake hose and front caliper

|

25-30

|

|

59

|

The

connecting bolt of brake caliper and mounting bracket

|

32~38

|

|

60

|

cross

screw on the front brake disc.

|

10~15

|

|

61

|

fixing

bolt of rear rear hub assembly and rear EPB brake caliper assy

|

65~75

|

|

62

|

Connecting

bolt of rear brake hose and rear EPB brake caliper

|

25-30

|

|

63

|

Connecting

bolt of rear EPB brake caliper and caliper's mounting bracket

|

30~35

|

|

64

|

cross

screws on the rear brake disc.

|

10~15

|

|

65

|

Connecting

nut of front brake hose and pipe

|

16~18

|

|

66

|

Connecting

nut of front brake hose and front brake caliper

|

25-30

|

|

67

|

Connecting

nut of rear brake hose and brake pipe

|

16~18

|

|

68

|

Connecting

nut of brake main pump and brake pipe

|

16~18

|

|

69

|

Exhaust

screw of rear EPB brake caliper

|

8~13

|

|

70

|

Connecting

nut of brake oil pipe and ESC controller

|

16~18

|

|

71

|

Variable

speed control mechanism fixing bolts

|

20~28

|

|

72

|

Variable

speed control mechanism fixing bolts

|

20~28

|

|

73

|

Connecting

nut of select&shift pull cable and bodywork

|

20~28

|

|

74

|

Connecting

bolt of shift rocker arm and transmission

|

20~28

|

|

75

|

Connecting

nut of pull road assy and transmission

|

20~28

|

|

76

|

Fixing

bolt of TCU assy and TCU mounting bracket

|

8~12

|

|

77

|

Variable

speed control mechanism fixing bolts

|

20~25

|

|

78

|

Variable

speed control mechanism fixing bolts

|

20~25

|

|

79

|

Connecting

nut of select&shift pull cable and bodywork

|

20~25

|

|

80

|

Fixed

Nut of Steering Wheel

|

42~52

|

|

81

|

The

connecting nut of upper end of steering column assembly and instrument piping

beam

|

20~25

|

|

82

|

The

lower end of steering column assembly and instrument piping beam connect with

cross bolt

|

25~30

|

|

83

|

The

connecting bolt of steering column assembly and steering shaft with universal

joint assembly

|

30~35

|

|

84

|

The

connecting bolt of steering shaft with univeral joint assembly and steering

gear assembly

|

30~35

|

|

85

|

The

connecting bolt of steering gear assembly and front subframe

|

95~105

|

|

86

|

The

steering tie rod ball pin and steering knuckle connect with slotted nut

|

40~50

|

|

87

|

Adjusting

nut of steering tie rod toe-in

|

50~55

|

|

88

|

Connecting

bolt and nut of rear suspension assembly and rear suspension bracket

|

100~110

|

|

89

|

Connecting

bolt of rear suspension bracket and transmission

|

70-80

|

|

90

|

Rear

suspension assembly and sub-frame connecting bolt

|

170~180

|

|

91

|

Left

suspension assembly and left suspension bracket connecting bolts and nuts

|

55~65

|

|

92

|

connecting

bolt and nut of left suspension assembly and bodywork

|

55~65

|

|

93

|

Left

suspension bracket and gearbox connecting bolt

|

55~65

|

|

94

|

Connecting

bolt of right suspension assembly and vehicle body

|

100~110

|

|

95

|

Connecting

bolt and nut of right suspension bracket and engine

|

55~65

|

|

96

|

Mounting

bolt of fuel tank

|

42~25

|

|

97

|

Mounting

bolt of fuel filler pipe guard plate

|

7~11

|

|

98

|

Fixing

screws of fuel tank diagnosis module

|

1.8~2.2

|

|

99

|

Fixing

nut of charcoal canister filter

|

7~11

|

|

100

|

Fixing

nut of fuel-delivery controller assy

|

4~6

|

|

101

|

Fixing

bolt of charcoal canister outer housing

|

4~6

|

|

102

|

Assembling

screw of fuel-delivery pipe's opening

|

7~11

|

|

103

|

Lock

snap ring of oil supply pump

|

250~450

|

|

104

|

assembly

bolt of electronic accelerator pedal

|

7~11

|

|

105

|

Fixing

bolt of radiator fan

|

5~8

|

|

106

|

Fixing

bolt of radiator

|

5~8

|

|

107

|

Fixing

bolt of expansion kettle

|

5~8

|

|

108

|

Fixing

bolt of oil cooler

|

8~11

|

|

109

|

Transmission

oil drain screw plug

|

10~12

|

|

110

|

Transmission

oil drain screw plug

|

18~24

|

|

111

|

Oil

level screw plug

|

18~24

|

|

112

|

Fixing

bolt of air accumulating plate

|

5~8

|

|

113

|

Fixing

bolt of air filter intake pipe

|

8~12

|

|

114

|

Fixed

bolt of air filter

|

8~12

|

|

115

|

Fixing

bolt of air filter bracket

|

8~12

|

|

116

|

Fixing

bolt of Intercooler air inlet pipe

|

8~12

|

|

117

|

Fixing

bolt of Intercooler outlet tube

|

17~25

|

|

118

|

Assembling

screw of Air filter housing

|

1.8~2.3

|

|

119

|

Fixing

bolt of exhaust manifold and secondary catalytic converter

|

45~55

|

|

120

|

Fixing

bolt of primary muffler assembly and secondary catalytic converter assembly

|

45~55

|

|

121

|

Fixing

bolt of primary muffler assembly and secondary muffler assembly

|

45~55

|

|

122

|

Fixing

nut of front oxygen sensor

|

40~60

|

|

123

|

Fixing

nut of rear oxygen sensor

|

40~60

|

|

124

|

Thermal

insulation board mounting nut

|

5~7

|

|

125

|

Self-Locking

Nut of Drive Shaft

|

290~310

|

|

126

|

Steering

knuckle and shock absorber assembly connecting nut

|

100~120

|

|

127

|

Lower

suspension arm ball and steering knuckle connecting nut

|

100~120

|

|

128

|

Wheel

speed sensor

|

10~15

|

|

129

|

wheel

nut

|

100~120

|

|

130

|

Connecting

nut of steering knuckle and steering tie rod ball joint

|

50~55

|

|

131

|

Fixing

bolt of bearing bracket

|

25-30

|

|

132

|

Fixing

bolt of thermal insulation cover

|

8~12

|

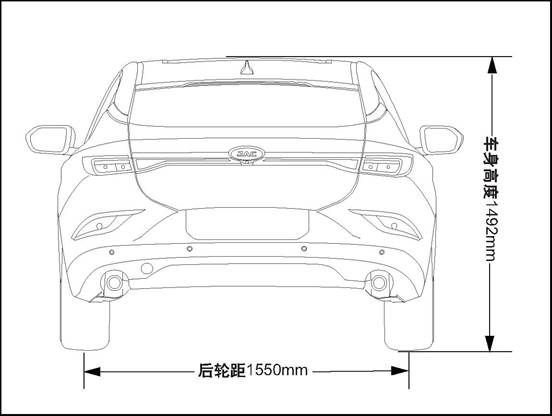

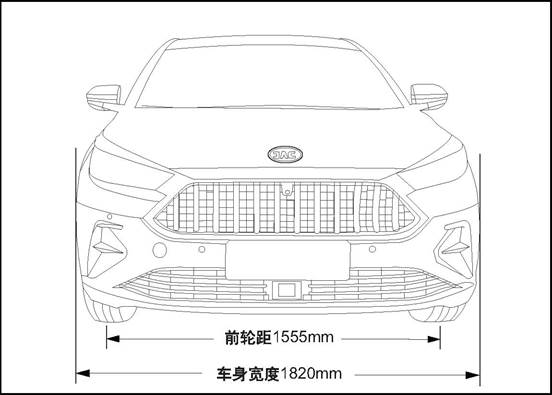

VIII. Vehicle certification

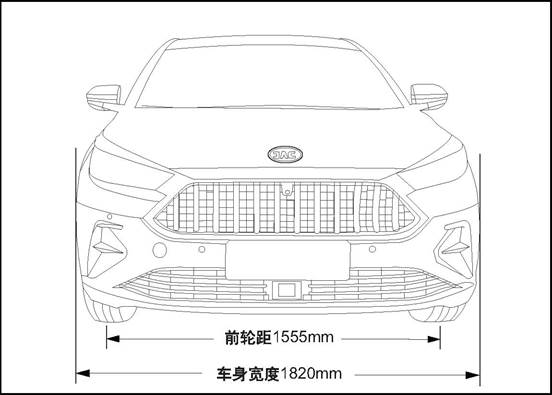

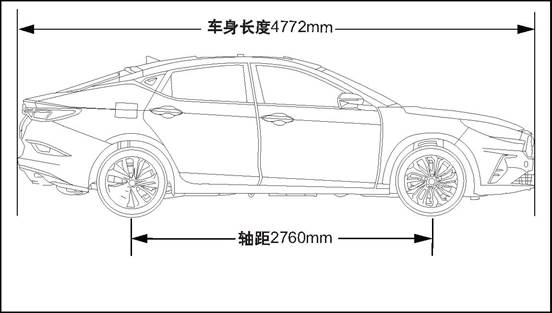

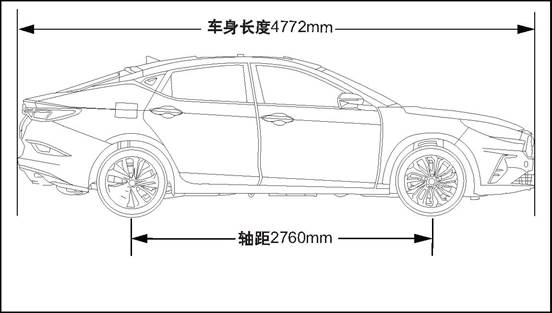

Front view

Side view

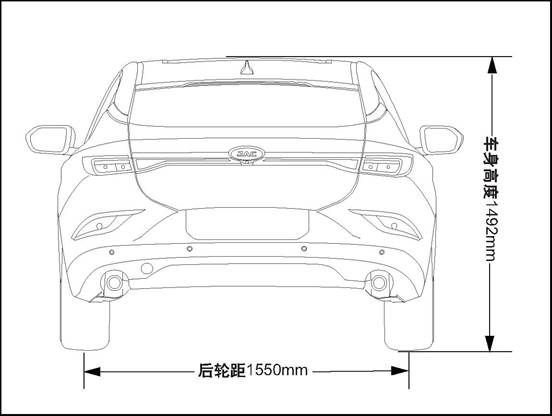

Rear view

(1) Vehicle dimensional

specifications

|

Item

|

Parameters

value

|

Unit

|

|

Total

length

|

4772

|

mm

|

|

Total

width

|

1820

|

mm

|

|

Total height

(empty load)

|

1492

|

mm

|

|

Wheelbase

|

2760

|

mm

|

|

Front

tread

|

1555

|

mm

|

|

Rear

tread

|

1550

|

mm

|

(2) Maintenance parameters 1-15

|

Item

|

1.5T+6MT

|

1.5T+CVT

|

Unit

|

|

passengers

|

5

|

5

|

Man

|

|

Curb weight

|

1432

|

1440

|

Kg

|

|

Maximum weight

|

1857

|

1865

|

Kg

|

|

Front axle’s load

|

967

|

977

|

Kg

|

|

Rear axle’s load

|

890

|

888

|

Kg

|

9.

Vehicle identification

(1)

Vehicle identification code

Vehicle

identification number

Vehicle

VIN is a legal identifier.

Vehicle

identification number (VIN) position

There

are several vehicle identification codes on the vehicle,and the following 10

are the most common:

1.

Located on the dashboard in the lower left corner of the windshield, VIN can be

seen through the windscreen.

2.

Under the front passenger seat.

3.

In the vehicle glove box.

4.

On the engine cover.

5.

Located in front of the front right door.

6.

Lower side of left B-column

7.

On the front of the left front door inner plate

8.

On the upper side of tailgate inner panel

9.

Refer to ECU data.

10.Refer

to MP5 data.

(2) Label

Vehicle certification

Vehicle certification

Tire information sign

Tire information sign

The

tire pressure label is attached to the driver's door side and the tire size and

cold inflation pressure can be seen on the label. The recommended cold

inflation pressure indicated on this label is the minimum tire pressure

required to support the vehicle's maximum load capacity.

10.

Noise, vibration and abnormal sound

(1) Diagnostic information and

process

Wind noise / air

sound

△

Warning Refer to drive shaft "Warnings about vehicle assistant

driving" in the "Warnings and Precautions".

△

Caution

When the

technician checks the repaired fault location, the assistant should drive the

vehicle. Otherwise, it may cause injuries.

You

must test the car in the car, in order to accurately confirm the location of

the wind noise. In general, wind noise has major and minor leaks. If all leaks

are not repaired during the repair, wind noise can only be reduced and wind

noise can not be completely eliminated. Test-drive maintenance staff must bring

the following tools to help diagnose the specific location of wind noise:

Stethoscope

Masking

tape

Stitch

seam

Marker

pen

screwdriver

Follow the procedure below to carry

out road test:

Select

a line, with east, south, west and north four different directions of the

straight street.

Choose

less traffic or less noise in the street, to avoid affecting the test.

The road test is conducted at the

speed at which the customer believes the noise is most pronounced or noisy, and

a speed limit of more than the legal limit is strictly prohibited.

The wind noise emitted under the

following conditions is external wind noise:

Wind

noise can be heard immediately while driving down the window glass.

When the tape is attached to the

various decorative seals and gaps, the wind noise disappears immediately.

Internal wind noise is caused by

air escaping from the vehicle and should be repaired as follows:

In

determining the location of the leak, attach the tape to the body lock pillar

relief valve. The air pressure will be formed immediately inside the car, and

the wind noise will be enhanced.

Use

a stethoscope to confirm the leak location.

Use

masking tape to temporarily repair leaks.

Continue

road test to confirm whether the wind noise is completely eliminated or other

leaked parts.

After

confirming all leaks by road test, return to the repair shop and make permanent

repairs with professional and reasonable positioning methods and sealing

materials.

Vibration

Most

of the high-speed vibration is due to the loss of dynamic balance of the wheel,

if there is still vibration after the dynamic balance is:

Tire

deformation

Rim

deformation

Tire

hardness deviation

Measurement of tire and

wheel free run out, can not detect all the causes leading to vibration, the

above three reasons for the load radial run out, you must use well-known tire

and wheel assembly to replace the original tire and wheel assembly, To carry

out maintenance on the faulty vehicle.

Low-speed vibration that occurs at

speeds below 64 km / h is usually caused by jerkiness. High-speed vibration at

speeds above 64km / h is usually caused by unbalance or run out.

Correct inhomogeneous

tires

There

are usually two ways to correct tires that are properly balanced but still

vibrate. One way is to use an automatic machine to attach the tire to the

machine and to rub a small amount of rubber from the high point on the pattern

on the left and right of the tire. Tire calibration using this method is usually

permanent. If this is done, there is no noticeable effect on the appearance of

the tire and on the life of the tire tread. It is not advisable to use a bladed

machine tool to correct the tire when calibrating the tire as this will shorten

the service life of the tire and will not fundamentally solve the problem.

Another way is to disassemble the

tire and turn the tire 180 ° on the rim. This method should only be used if it

is confirmed after diagnosis that the tire and wheel assembly are causing

vibrations. This is because this method is equally likely to cause vibration of

the intact wheel assembly.

Abnormal sound

When

the engine speed is high, the car makes a squeaky check if the insulation panel

touches the bottom of the car body.

Lift

the vehicle and perform a visual inspection

Bend

the insulation panel slightly to create a gap between it and the bottom of the

vehicle body.

The front of the

vehicle squeaks when the weather is cold

Check

the balance bar isolation rubber sleeve

Cold

Road Test vehicle and pass the bumpy road, so that the front suspension can

reach maximum travel.

Remove

the isolation rubber sleeve and tape the front stabilizer bar, reinstall the

isolation rubber sleeve on the tape.

Bumpy rear bass

issued by the boring abnormal sound

Check

if the spare tire in the luggage compartment is properly secured

Open

the luggage compartment and inspect the spare tire and driver's tools.

Re-tighten

spare tires and truck tools.

Test

vehicle to check whether abnormal sound has been eliminated.

The rear of the

vehicle emits a glass percussion while traveling on a bumpy road

Check

the rear door lock is not properly adjusted

Road

test vehicle to check this situation.

Loosen

the lock nut and adjust the lock.

The door squeaked

Check

if the harness connector inside the door trim panel creaks

Tap

the trim plate and pay attention if you hear a squawk

Remove

the door trim and wrap the foam padding around the harness connector according

to the actual vehicle conditions.

Squeaking when using

the door

Check

door hinges for lack of lubrication.

Push

the door back and forth and listen carefully to check whether the door squeaks.

Use

rust inhibitor to lubricate the door hinge and apply grease.

A manual transmission

squeaks when shifting gears (when the weather is cold and appears in a cold

state)

Check

manual gearbox lower shifter assembly

Switch

the shift lever between the stops and see if any squeaks appear.

Remove

floor console and replace shift lever lower boot or lower boot with talc.

(2)

Maintenance guide

Wind noise / air

sound

External wind noise

Repair methods of wind noise

leakage and water leakage are similar, refer to he diagnostic information and

procedures. The actual repair procedure depends on the type of sealing

components being repaired.

Vibration

Wheel and tire

balance on the car

Keep

wheel balance with E-car balancing machine Balancing machine is easy to use,

both for static balance, but also for dynamic balance. The difference between

balance on the car and balance under the care is that the imbalance of brake

disc can not be corrected under the car. However, the accuracy of the

under-ride balance overcomes this disadvantage by securing the wheel to the

balancing machine so that a cone passes through the back of the center hole

without passing through the wheel nut bore.

Wheel and tire

balance under the car

On-board

balance corrects vibrations due to disc brake imbalance.Wheel and tire balance

on the car

△

Warning Lower support arms are supported in a normal horizontal position to

avoid damaging the trans-axle. When the wheel sink to reach the full stroke, do

not hang up the operation of the vehicle.

It

is forbidden to disassemble the balance weight that the wheel installs when the

car is under dynamic balance when carrying out dynamic balance operation on the

car.

If

you need to add more than 25g when balancing, then divide the balance into two

pieces, install them on inner and outer rims respectively.

Spin

the driven wheel and wheel assembly with the engine.

Wheel

and tire orientation with the assembly

Wheels

and tires are factory fitted and fitted to match the thicker part of the tire

(also known as the high point) to the minimum radius of the wheel, also known

as the low point. At the very beginning of the tire factory, the high point of

the tire was initially marked with a red paint mark or affixed to the outer

wall of the tire.

Wheel

low for the valve core position.

Before

removing the tire from the wheel, make a mark on the tire valve core position

to ensure that it can be installed to its original position. Before removing

the tire from the wheel,

make

a mark on the tire valve core position to ensure that it can be installed to

its original position.

Abnormal sound

Repair of abnormal

sound

Abnormal

sound comes mainly from the relative motion that should not exist between the

vehicle parts. There are three ways to repair abnormal sound:

Firmly

tighten the parts so that there is no relative movement of the vehicle during

driving.

Separate

parts so that parts do not come into contact with them at work.

Isolate

parts so that there is no abnormal noise when parts move. A uniform surface

with low-friction can be used to eliminate sticking slip between parts.

11.

Tool purchasing channel and diagnosis device

△Note:

If you want to buy special tool, please contact 4S shop in each area of JAC.

For contact information, please contact 4008889933.

|

No.

|

Diagnosis device type

|

Diagnosis device version

|

Tool

No.

|

|

1

|

3G-X431

|

V11.70

|

JAC-T1Z002

|

Clutch and control system

I Overview

(1) Structure Outline

structure outline

The clutch

assembly is located between the engine and the transmission. The clutch

pressure plate assembly is fixed on the rear plane of the flywheel by a bolt.

The clutch driven disk is connected with the input shaft of the transmission

through a spline so as to slide axially and transmit torque in the

circumferential direction . As the car travels, the driver can disengage and

gradually engage the engine and transmission to cut off or transmit engine

input power to the transmission as the driver steps on or off the clutch pedal.

The

clutch system mainly includes the following components:

Active: Clutch pressure plate

assembly

Clutch pressure plate assembly

bolted to the flywheel.

Follower: clutch driven disk

The

clutch driven plate is splined to the transmission input shaft. Active parts

and followers by spring pressure to maintain contact. The pressure is applied

by the diaphragm spring in the platen assembly.

Control:

Clutch control system includes clutch pedal, master cylinder, tubing, and

release bearings

Clutch pressure plate, clutch driven plate structure

drawing

1.Rear shock absorber

2.

Disassemble clutch hose assembly

3.

Main cylinder oil outlet hard pipe assembly

4.

Clutch main cylinder and oil inlet pipe assembly

5.

Clutch housing

6.

Clutch pressure plate assembly and driven plate

7.

Hydraulic separating bearing

Clutch pressure

plate, clutch driven plate structure drawing

1.

Clutch cover & pressure plate assy.

2.

clutch driven disk

3.

Hexagon bolt, spring washer and flat washer assembly

Clutch main cylinder

1.

Air Inlet Pipe

2

cylinders

3.

Sensor

4.

Shaft pin

5.

gasket

6.

Split pin

(2) Maintenance

parameters

Maintenance

parameters

|

No.

|

Item

|

Parameter

|

|

1

|

clutch

free travel stroke

|

6~20mm

|

Lubricating

Grease

|

No.

|

Item

|

Brand

|

|

1

|

Master

cylinder master pin

|

Kunlun No.2 low temperature lubricating

grease

|

(3) Torque parameter

|

No.

|

Item

|

Torque

(N·m)

|

|

1

|

Clutch pull cable bracket fixing bolt

|

18~22

|

|

2

|

Clutch main cylinder

and oil inlet pipe assembly

|

18~22

|

|

3

|

Main cylinder oil outlet hard pipe

assembly

|

20~28

|

|

4

|

The clutch pedal and the main clutch

pump and intake pipe installation

|

20~28

|

|

5

|

Clutch pedal fixing bolt

|

20~28

|

|

6

|

Clutch pressure plate mounting bolt

|

20~28

|

|

7

|

Main cylinder oil outlet hard pipe

assembly

|

18~22

|

(4) Special tools

|

No.

|

Tool No.

|

Tools

|

Outside

View

|

Description

|

|

1

|

JAC-T1F011

|

Flywheel stop

|

|

Fixed flywheel

|

△Note:

If you want to buy special tool, please contact 4S shop in each area of JAC.

For contact information, please contact 4008889933.

(5).

Maintenance precautions

Cautions

The

recommended clutch hydraulic oil is the brake fluid "DOT 4".

•

Do not reuse the discharged clutch hydraulic oil.

•

Be careful not to spill the clutch hydraulic oil onto the body finish.

Do

not use mineral oil such as gasoline or kerosene, otherwise it will corrode the

rubber parts in the hydraulic system.

Please

don’t disassemble master cylinder and slave cylinder.

△

Warning Clean the clutch brake pad. Please use a vacuum cleaner, do not use

compressed air cleaning.

Maintenance

points

△ NOTICE Do not operate the system

using a vacuum pump or any other type of emptying power unit.

Check the liquid level of the

clutch hydraulic oil. Make sure the level is normal.

Do not let the clutch hydraulic oil

fall on the body paint or other parts. If the clutch hydraulic oil splashed on

the body paint or other parts, immediately wipe with a dry cloth.

Ⅱ Troubleshooting

(1)

common fault diagnosis

Clutch

assembly and clutch control system performance diagnostics should be performed

by an experienced driver or a skilled automotive service technician.

The following (trouble) diagnoses

involve common problems and possible causes. After making appropriate

diagnoses, make adjustments according to the appropriate solutions in the

diagnostic tables and the appropriate chapter for each specific procedure in

the service manual, or replace the parts as required.

During vehicle service, the clutch

plate and the clutch plate can not be repaired. If any one of them is broken,

replace the entire assembly.

If

the clutch driven plate rivets wear or clutch driven disk by the oil or grease

dirty, you can no longer use the clutch plate. If you need to change a part,

use a new, quality part to replace it. This diagnostic table helps to diagnose

malfunctions of the clutch system caused by the following conditions: Inability

to separate, incomplete separation, incomplete engagement, slipping, noise,

jitter.

Shake

The

numbers in this diagnostic table do not imply the order of examinations, and

there is no prior relationship between the various possible causes.

(2) fault diagnosis table

|

No.

|

Fault symptoms

|

Fault analysis

|

Solutions

|

Remark

|

|

1

|

Can not be separated

|

Failure to disengage means that the

clutch cannot function and cannot cut off the power transmitted from the

engine.

Failure to

disengage means that the clutch cannot function and cannot cut off the power

transmitted from the engine.

Check the following

conditions:

1. Clutch release

lever deformation.

2. Film spring

deformation.

3. Diaphragm

spring support ring fracture.

4. Clutch brake

pad is bonding with flywheel or clutch pressure plate

|

Replace parts

those has deformation, wear,

fracture

Adjust the clutch

system.

|

|

|

2

|

Incomplete

separation

|

A half-way clutch separation will cause

abnormal cut-off

The power

transmitted from engine. The transmission rod will be difficult to operate

since the the clutch friction plate and transmission input shaft are keep

rotating.

Check the

following conditions:

1. When clutch

brake pad has deformation,it will swing under rotating

2. Clutch brake

pad damage.

3. The spline of

clutch brake pad does not match with the input axis of the transmission,or

the spline surface is damaged

4. Clutch brake

pad is bonding with flywheel or clutch pressure plate

Clutch pressure

plate

5. Flywheel/

clutch pressure plate/ clutch brake pad thickness exceed regulated size.

|

Replace parts those has deformation、wear、fracture and sizes out

of regulation If the clutch brake pad does not work well with the

transmission input axis spline,replace the pad,even replace the input axis if

it is necessary. If the clutch brake pad exceeds the specified size or is

damaged, replace it. Replace the clutch thrust bearing that does not apply.

Adjust clutch system to remove unnecessary clearance and eliminate mechanical

failure. Reinstall the unbefitting parts.

|

|

|

3

|

Incomplete joint

|

A half-way clutch separation will make

engine unable to transmit engine power to

transmission’s input shaft, and the clutch friction plate will slip

Clutch brake pad

Check the following conditions:

1. Clutch brake pad is contaminated with

oil or grease.

2. Clutch brake

pad damage.

3. Clutch pedal

has no free travel.

4. Film spring/clutch pressure plate/clutch

release lever/Clutch brake pad

spline damage or wear

|

Replace parts those has

deformation, wear, fracture. Replace clutch brake pad or replace the abnormal

clutch assembly Adjust the clutch pedal free travel correctly. Adjust clutch

system to remove unnecessary clearance and eliminate mechanical failure.

Reinstall the unbefitting parts.

|

|

|

4

|

Slipping

|

The slipping of the clutch friction

plate can cause the engine to fail to transfer power properly.

Power

Check the

following conditions:

1. Clutch brake

pad wear.

2. Clutch brake

pad is contaminated with oil or grease.

3. Clutch

Incomplete joint.

4. Flywheel/

clutch pressure plate/ clutch brake pad thickness exceed regulated size. The

friction surface has exceeded set specification.

5. Excessive high

temperature in the clutch housing caused by improper driving too high

6. Installed the

poorly assembled clutch.

|

Replace parts

those has deformation, wear,

fracture

and sizes out of regulation.

The solutions of

“ incomplete release” and “ Incomplete joint ”.

The solutions of

“ incomplete release” and “ Incomplete joint ”.

shut off the

engine and cool down the temperature inside clutch’s outer housing, then make

further diagnosis.

Temperature is

too high.

Install the

specified clutch.

Reinstall the

unbefitting parts.

Do not place your

feet on the clutch pedal while driving.

|

|

|

5

|

Noise

|

Check the following conditions:

1. Poorly assembled

clutch brake pad.

2. Poor balance.

3. Clutch thrust

bearing malfunction.

4. Clutch brake

pad torsional damping spring is damaged.

|

Replace parts those has deformation,

wear, fracture.

Install specified

clutch brake pad.

If there is poor

balance part,replace the clutch assembly

Brake Assembly

Reinstall the

unbefitting parts.

|

|

|

6

|

Jitter

|

This occurs when the clutch brake pad is

unable to engage the flywheel gently.

Check the

following conditions:

1. Clutch brake

pad damping spring does not meet specifications.

2. Clutch brake

pad does not meet specifications.

3. Clutch brake

pad is contaminated with oil or grease.

|

Replace clutch

assembly

|

|

III.

clutch pedal free travel adjustment

(1) Special tool (none)

(2)

Adjustment

1. Adjust the clutch pedal free

travel

1. Adjust the clutch pedal free

travel

1) Slide the clutch pedal to the

end and measure the clutch pedal stroke at the start position to the end

position

2) Loosen the lock nut and turn the

bolt to adjust the clutch pedal stroke. Tighten the lock nut after adjustment.

△

CAUTION When adjusting the clutch pedal height, do not push the push rod to the

clutch master cylinder.

Clutch

master cylinder

3) Handle the clutch pedal by hand to determine when

the pedal has a resistance. The clutch pedal has a free stroke

3) Handle the clutch pedal by hand to determine when

the pedal has a resistance. The clutch pedal has a free stroke

Standard

size 6 ~ 20mm

4) Loosen the lock nut and turn the

fader, adjust the clutch pedal free travel, adjust the tightening lock nut

5)

Clutch pedal free travel should be within the standard value.

△

CAUTION If the free stroke of the clutch pedal is out of the specified range,

there must be air in the clutch hydraulic line or the master cylinder has a

fault.

.

. Please

exhaust the air inside system and dismantle and check master cylinder or

clutch.

IV. the hydraulic clutch exhaust

(1)

Special tool (none)

(2)

exhaust operation steps

△ Note: The system should be vented

when removing the clutch line, the clutch master cylinder, the clutch slave

cylinder and the clutch, the clutch pedal is soft, please discharge air in the

system.

1.

Exhaust the air in the pipeline

1.

Exhaust the air in the pipeline

Loosen

the exhaust plug of the clutch slave cylinder.

2).

Slowly depress the clutch pedal until the air is completely discharged.

3).

Tighten the pedal completely and hold, tighten the exhaust bolts.

4)

Fill the hydraulic fluid of the clutch hydraulic system.

4)

Fill the hydraulic fluid of the clutch hydraulic system.

△

CAUTION Always keep the liquid level in the reservoir between MIN and MAX.

5) Repeat the above steps until the

system discharges the clutch hydraulic oil clean and does not contain air

bubbles.

2.

Make sure the clutch is working properly.

1) Start the engine, depress the

clutch pedal, after about 2s carefully into the reverse gear. If there is more

noise in the selection, fully apply the clutch pedal 5 times to vent the

system.

2)

Wait for about 30s, then check the clutch work. If there is still loud noise,

repeat the exhaust.

V.

Clutch main cylinder and oil inlet pipe assembly

(1)

Special tool (none)

(2) Disassembly

1.

Open the engine cover

2.

Clutch main cylinder and oil inlet pipe assembly

1)

release clutch hydraulic oil from clutch air outlet valve. During dismantling

process, press and hold clutch pedal and prevent the hydraulic oil from

leaking.

2). Disconnect the shaft pin, washer and split pin

between clutch main cylinder and oil-inlet rod and clutch pedal

2). Disconnect the shaft pin, washer and split pin

between clutch main cylinder and oil-inlet rod and clutch pedal

3). Disconnect the

2 connecting nuts which connects clutch pedal and clutch master cyliner and

oil-inlet pipe

3). Disconnect the

2 connecting nuts which connects clutch pedal and clutch master cyliner and

oil-inlet pipe

4). Disconnect the

fixing bolt of main cylinder tube and bodywork

4). Disconnect the

fixing bolt of main cylinder tube and bodywork

5). Disconnect the connecting nut of main cylinder

pipe and clutch amin cylinder and oil-inlet pipe. Then disconnect the pipe.

5). Disconnect the connecting nut of main cylinder

pipe and clutch amin cylinder and oil-inlet pipe. Then disconnect the pipe.

6). Dismantle the fixing clamp ring, then disconnect

the connecting hose of clutch main cylinder and oil-inlet assy and brake oil

kettle.

6). Dismantle the fixing clamp ring, then disconnect

the connecting hose of clutch main cylinder and oil-inlet assy and brake oil

kettle.

7). Disconnect the clock spring

wire harness connector.

7). Disconnect the clock spring

wire harness connector.

8)

Clutch main cylinder and oil inlet pipe assembly

(3)

Inspection

1.

Check the clutch line

1).

Check clutch line for blockage.

2)Check

clutch hose and tube for damage or rust damage.

(4)

Installation

1.

Clutch main cylinder and oil inlet pipe assembly