Preface

To

help JAC authorized professional maintenance technicians for effective and

proper maintenance and repair of JAC J7 transmission, we compile this

transmission maintenance manual. The MF622D35 gearbox is suitable for the J7 manual transmission model equipped with a 1.5T

engine. The CVT automatic transmission is suitable for the J7 automatic transmission model equipped with a 1.5T

engine.

All

contents of this manual, including pictures and technical parameters, are

up-to-date. If maintenance is affected due to product improvement, JAC

Passenger Vehicle Marketing Company will provide technical notices or

supplementary volumes. Therefore, you should pay close attention to obtain

relevant information when using this manual 'S latest developments. JAC

reserves the right to make changes in product design, additions or

improvements.

This

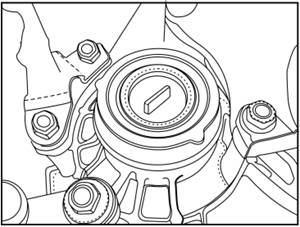

manual may not be copied or modified in any form, including but not limited to

electronic, paper, audio-visual, mechanical, etc., without the written

authorization of JAC Passenger Car Marketing Company.

The

final interpretation of this manual belongs to JAC. During the process of

maintaining JAC transmission, if use non-genuine parts of JAC or disqualified

oil, the transmission may be damaged.

Anhui Jianghuai Automobile Group Co., Ltd

September 2019

I.Structure Outline

The continuous change

of the transmission ratio can be achieved by a speed change device which

consists of two opposed cone wheels and a V-shaped transmission steel belt

surrounding the two wheels. The transmission ratio of the transmission is

transmitted to the differential in the transmission through the countershaft.

This manual briefly

introduces the transmission, including the design and function of each part of

the transmission, and describes the dynamic transmission and control device. In

addition, this manual also outlines the transmission's oil cooling system and

external gear shifting mechanism.

The

transmission's stepless shift mode allows you to drive more comfortably and

improves vehicle performance. Using this automatic transmission has the

following advantages:

-

In the condition of constant speed, the engine speed is low;

-

Improve emission control/reduced fuel consumption;

-

NVH (noise, vibration, jangle) is small;

-

Accelerate smoothly;

-

Drive flexibly on mountain roads;

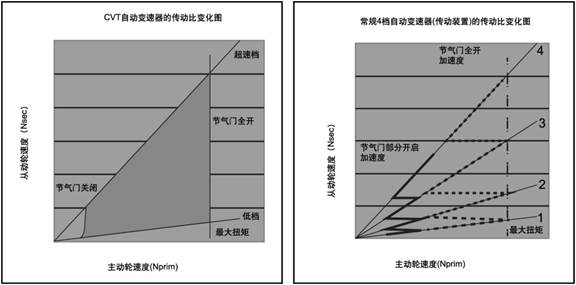

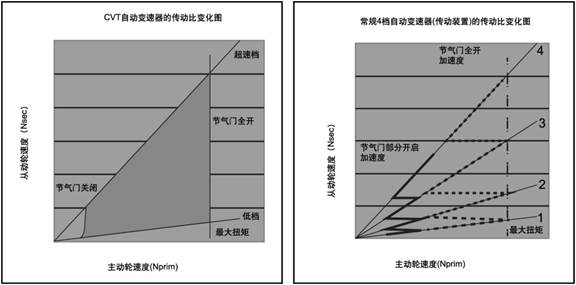

1.1Comparison

of traditional automatic transmission and CVT transmission

The following figure

shows the comparison of transmission ratio between CVT and manual or

conventional automatic transmission. The transmission ratio of a conventional

automatic transmission is a series of fixed values.

When the transmission

is in high gear, the transmission ratio shown on the right figure will vary

along the thick solid or dashed line according to the opening degree of the

throttle valve. However, with CVT transmission, the transmission ratio

variation diagram is shown on the left. The shift points of both transmissions

are related to the opening degree of the throttle valve operated by the driver.

When

the opening degree of the throttle valve becomes larger, the engine speed

increases and the transmission changes into high gear.If use the traditional transmission,

the engine speed will be significantly reduced, but use the CVT transmission,

the engine speed will not reduce. In the condition of constant engine speed,

CVT transmission can be rotated into high gear by moving cone (see below). In

addition, there are other gear shift strategies available, which will help the

new user of CVT transmission accept it more quickly.

Drive

wheel speed (Nprim)

|

|

Throttle

valve partly open acceleration

|

|

Drive

wheel speed (Nprim)

|

|

Throttle

valve fully open acceleration

|

|

Throttle

valve fully open

|

|

Transmission

ratio change figure of conventional automatic transmission

|

|

Transmission

ratio change figure of CVT automatic transmission

|

|

Speed ratio change diagram of CVT transmission (left)

and 4-gear automatic transmission (right)

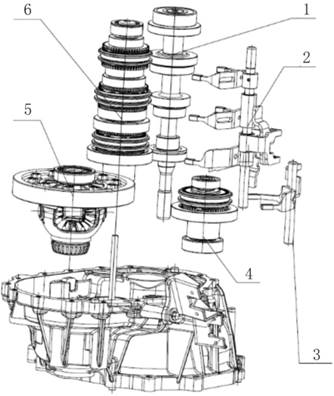

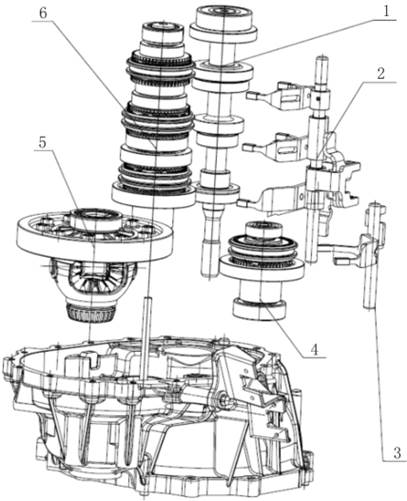

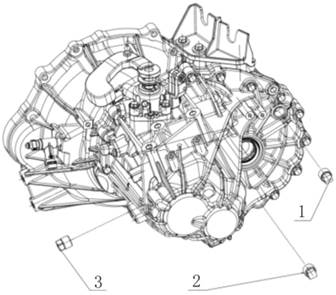

1.2

Transmission Schematic Diagram

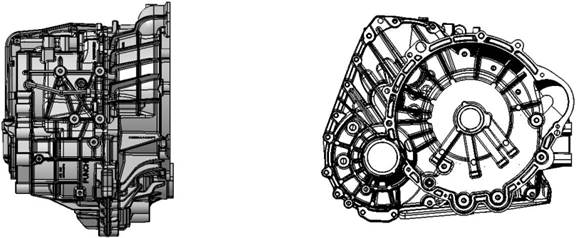

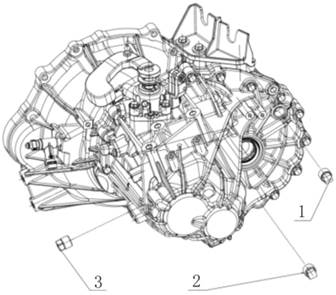

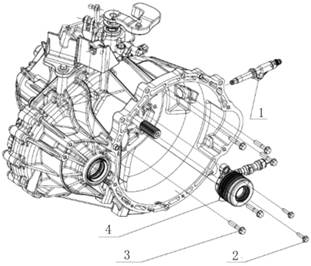

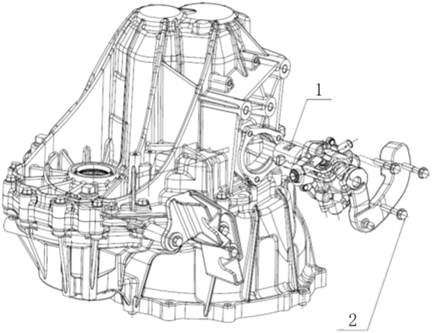

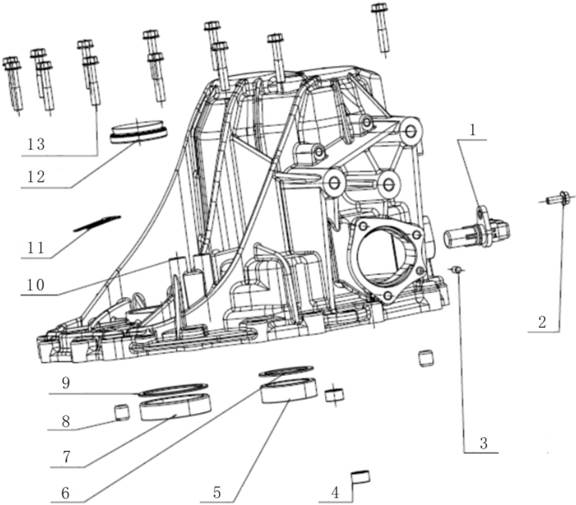

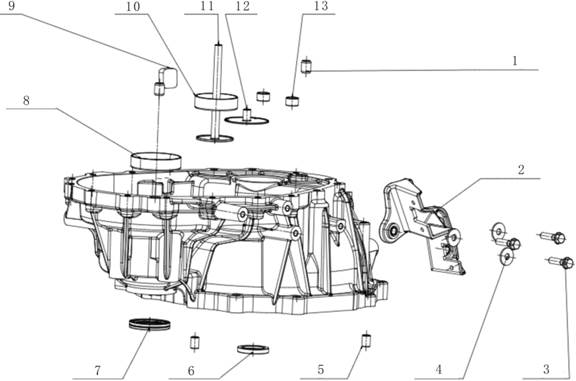

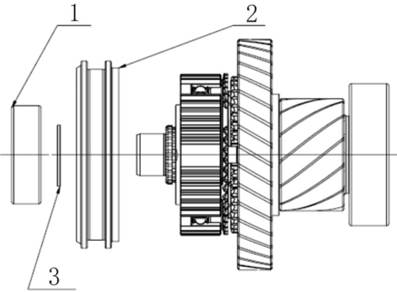

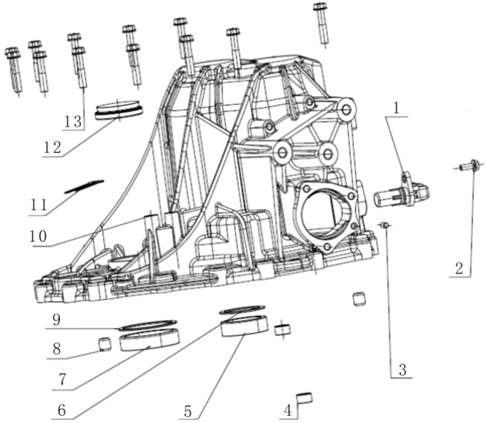

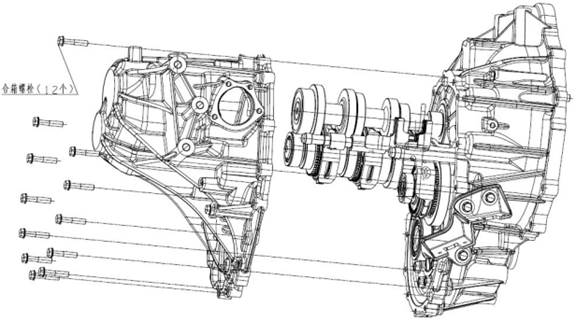

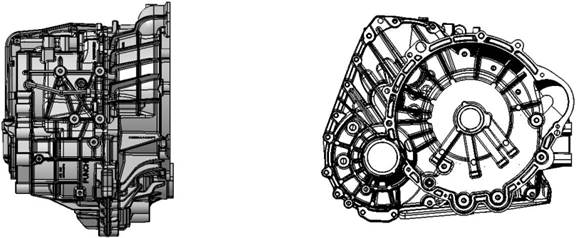

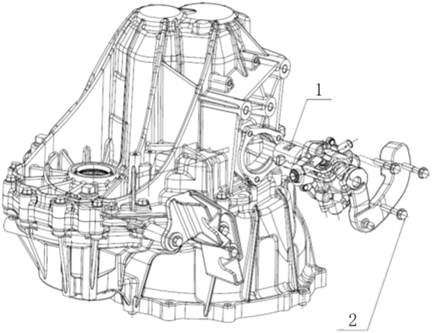

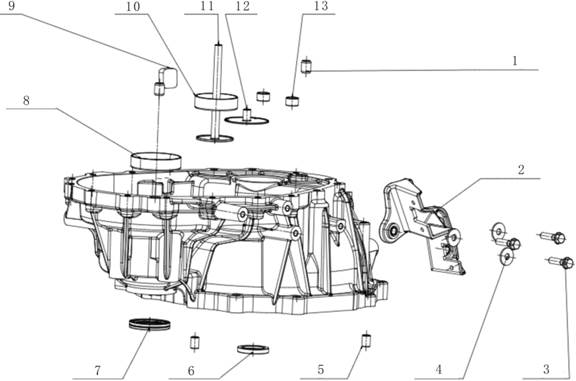

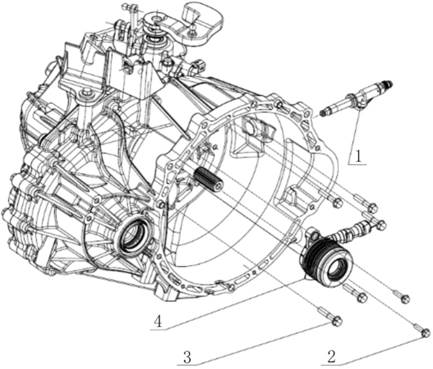

1.2.1 Transmission

Three View Drawing

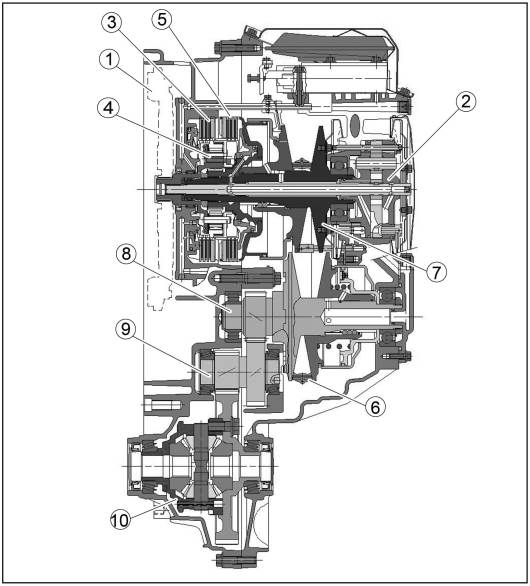

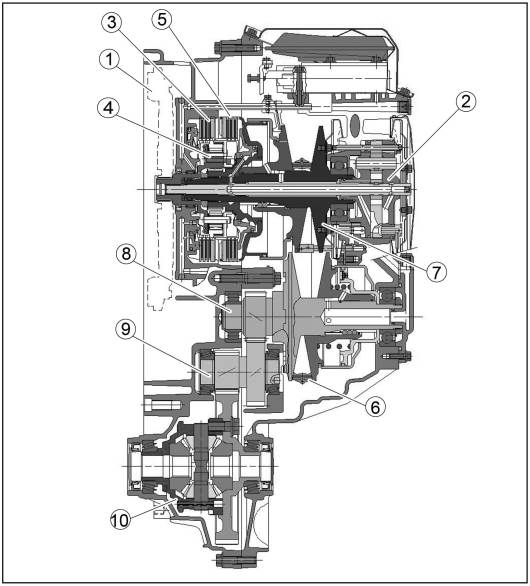

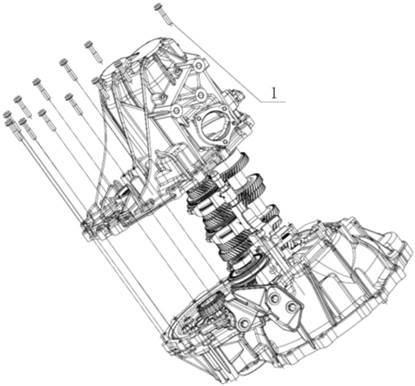

1.2.2 Transmission

Cutaway View

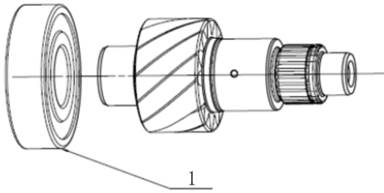

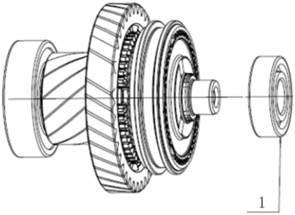

1.

Torsional shock absorber/Flywheel

2. Oil Pump

3.

Backward clutch

4.

Planet mechanism

5.

Forward clutch

6.

Steel belt

7.

Drive bevel gear

8.

Driven bevel wheel

9.

Countershaft

10.

Differential

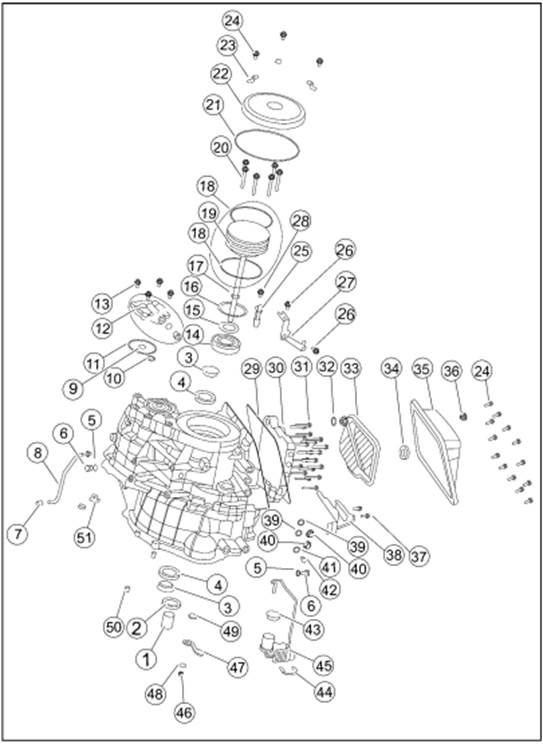

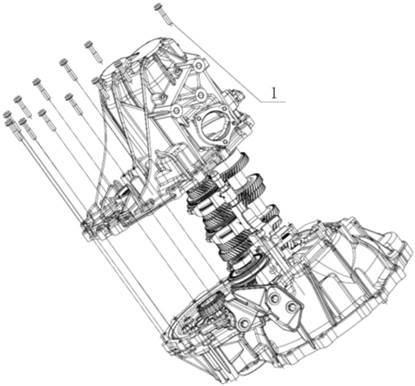

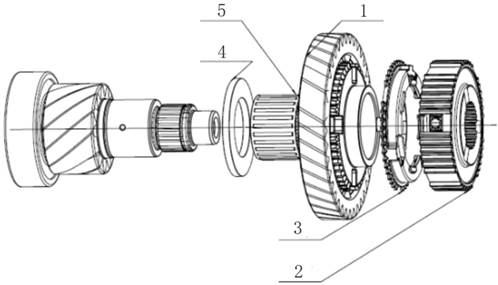

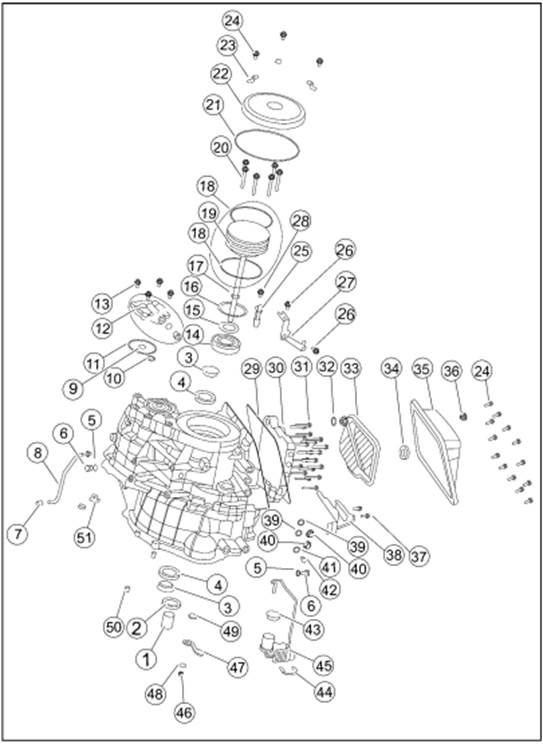

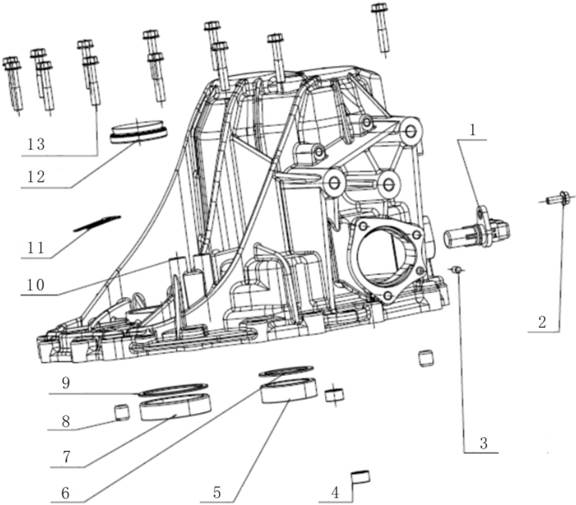

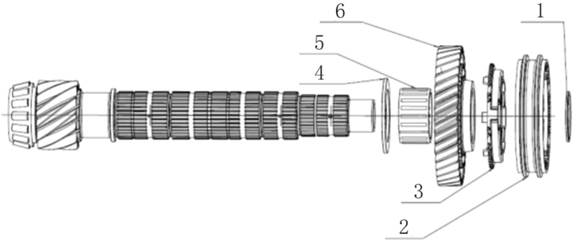

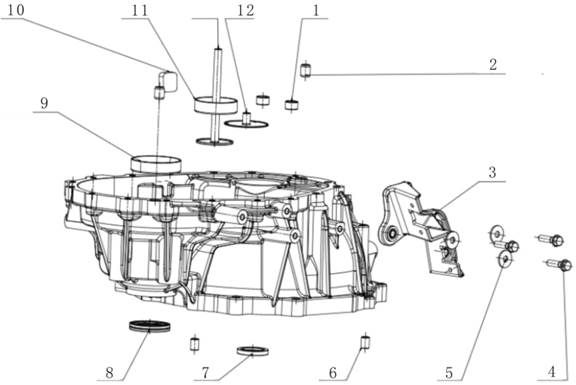

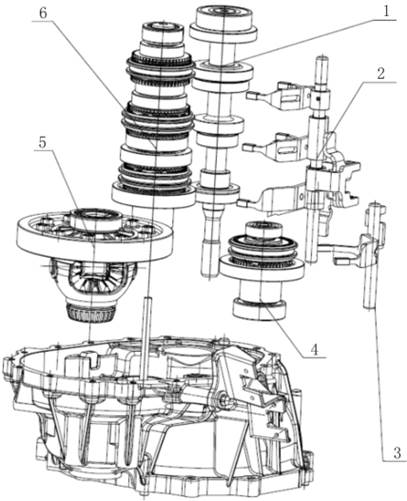

1.2.3 Transmission

Exploded View

1.

Input shaft rubber guard sleeve 482235 26. Differential speed

sensor bracket fixing screw 481289

2.

Input shaft oil seal 481274 27. Differential speed sensor

bracket 482468

3.

Differential oil seal cover 481296 28. Revolution speed

sensor fixing bolt 481283

4.

Differential oil seal 483329 29. Oil pan washer 482504

5. Oil

filling screw plug washer 481247 30. Valve body assembly

482589

6. Oil

filling screw plug 481248 31. Valve body bolt 481311

7.

Breather pipe cap 483420 32. Plastic buckle 482253

8.

Breather pipe assembly 483114 33. Oil filter assembly

483165

9.

Driven bevel wheel shaft end cover O-type ring (small) 481254 34. Oil pan

magnet 481870

10.

Driven bevel wheel shaft end cover sealing ring 481877 35. Oil pan assembly

11.

Driven bevel wheel shaft end cover O-type ring (big) 481255 36. Oil drain

screw plug 482442

12.

Driven bevel wheel shaft end cover 482982 37. Driving mode

sensor fixing screw 481090

13.

Driven bevel wheel shaft end cover countersunk screw 482208 38.

Driving mode sensor 482493

14.

Drive bevel wheel shaft ball bearing 482294 39. Oil cooler screw

plug O-type ring 481258

15.

Drive bevel wheel shaft nut 481293 40. Oil cooler screw plug

482121

16.

Conical spring washer 481856 41. Oil level screw plug washer

481249

17. Oil

pump sealing ring 481826 42. Oil level screw plug 481250

18. Oil

pump O-type ring 481259 43.Main connector cover 482104

19. Oil

pump (with O-type ring) 483323 44.Main connector buckle 482105

20. Oil

pump bolt 481284 45.Main connector and inner wire

harness 482475

21.

Drive bevel wheel shaft end cover O-type ring 481253 46. Gear select

pull rod nut 481329

22.

Drive bevel wheel shaft end cover 481173 47. Gear select pull

rod 483185

23.

Drive bevel wheel shaft end cover buckle 481189 48. Gear select

pull rod nut washer 482584

24.

Drive bevel wheel shaft end cover bolt 481283 49. Oil seal (gear

select shaft) 482099

24. Oil

pan bolt 481283 50. Locating pin 483138

25.

Revolution speed sensor 482410 51. Metal buckle 481456

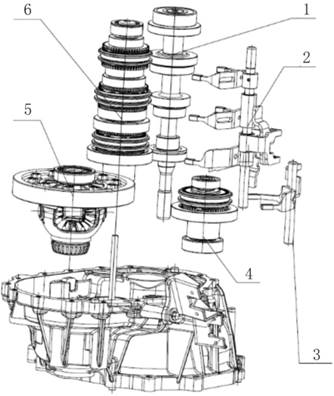

2. System Working Principle

These

components can be divided into three groups according to the corresponding

functions of the VT3 transmission:

·

Group 1 - mechanical transmission device. This part is designed to provide

mechanical transmission and torque transfer.

· Group 2 - control system and control system related

components. According to the load condition and driving requirement, the

control system ensures that the transmission transfers power and changes the

transmission ratio at the appropriate time.

· Group 3 - external

connecting device and some components that are connected to the external of

transmission. Some of these components are located in or connected to the

transmission, while others are part of the overall system but are distributed

elsewhere in the vehicle.

2.1

Mechanical Torque Transmit

2.1.1 Planet Mechanism

The

planetary mechanism enables the transmission to provide forward and backward driving

torque. The torque provided by the engine is usually transmitted to the

transmission through the input shaft on the planetary carrier. The multi-plate

clutch engaged in the forward direction can directly connect the planetary

carrier to the solar gear. At this point, the planetary carrier and the solar

gear become a rotating whole through engagement, and the engine torque is

directly transferred to the drive gear. The planetary gear does not transmit

any torque, so there is no mechanical loss to the planetary mechanism, and the

drive gear will rotate in the same direction as the engine. This is the forward

mode.

In

the reversing mode, engaging the reversing multi-plate clutch can keep the gear

ring in the planetary mechanism still, and the planetary carrier drives the

three pairs of planetary gear sets to make the solar gear rotate in the

opposite direction. At this time, the gear set's transmission ratio is 1:1.1,

and slight deceleration and torque increasing will occur to compensate for the

friction loss of the planetary mechanism.

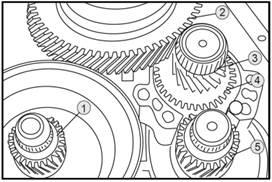

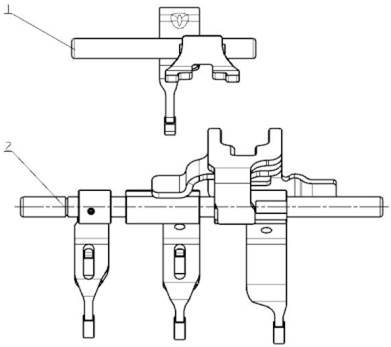

Planet

mechanism

1. Planet gear

2. Input shaft

3.

Solar gear

4. Gear ring

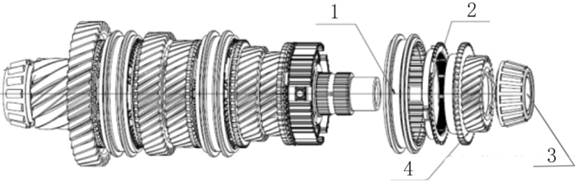

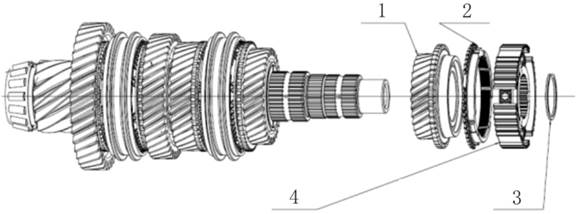

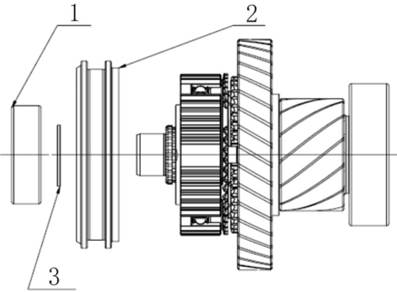

2.1.2 Multi-disk

Clutch

There

are two sets of multi-disc wet clutches: one for forward and one for backward.

Each group of clutches has three friction plates with a total of six friction

surfaces. The hydraulic system controls the clutch to enable the vehicle to

move forward smoothly when the throttle valve is in any open degree. When drive

gear is engaged, controls the clutch engagement quantity to enable the vehicle

to stop. Cooling oil directly cools the clutch plate to prevent the friction

surface from overheating.

Clutch

in planet mechanism

1.

Forward clutch group 2. Backward clutch group

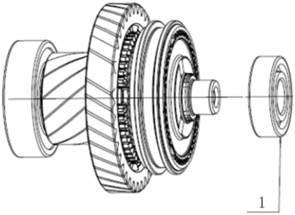

2.1.3 Bevel Gear and

Steel Belt

The main design feature

of the CVT transmission is a pair of V-shaped bevel gear connected by a steel

belt. The center distance between the drive gear and the driven gear is 155mm.

Each bevel gear is divided into two half: one half is fixed, the other half

slides along the axial direction, the inclination angle of both are 11°. The

24mm wide "Van Doorne" push-drive belt is used to transfer torque

between wheels (a 30mm belt is available for larger torque values). Lubricate

and cool the belt with a nozzle by means of an oil jet. To reduce the angle

error of the transmission belt when shifting gears, two moving half-wheels are

placed on the diagonal of the two, and each moving half-wheel is connected to

the hydraulic cylinder/piston. Hydraulic pressure is controlled by control

system, see "control system". Spherical splines prevent moving the

half wheel relative to their fixed half wheel rotation.

Since the sun wheel is

splined to the active cone wheel, the torque transmitted by the planetary gear

set can be directly applied to the active cone wheel. The steel belt transfers

power from the driving cone to the driven cone, and then from the driven cone

to the intermediate gear shaft.

The torque and speed of

the driven wheel are determined by the position of the belt. The size of the

two wheels is designed to provide a transmission ratio of 2.416:1 ~ 0.443:1,

with the maximum transmission ratio 5.45 times of the minimum one. The fuel

consumption is lowest when overspeed transmission ratio.

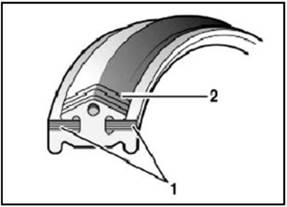

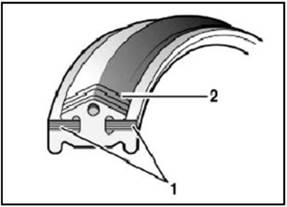

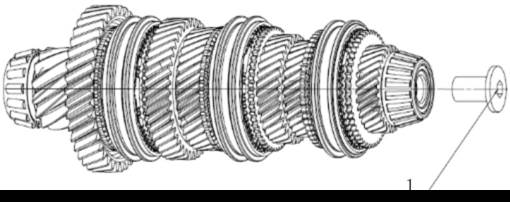

The

transmission steel belt consists of 450 steel plates and 24 steel belts fixed

together with 12 steel belts on each side.

The

drive belt

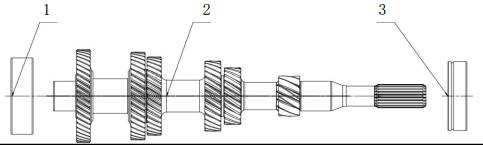

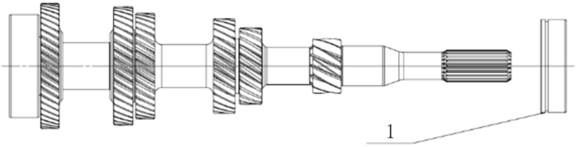

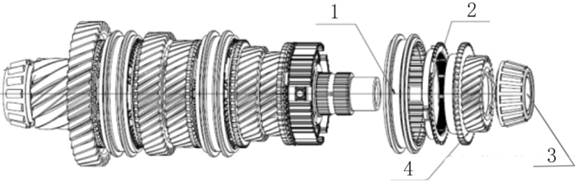

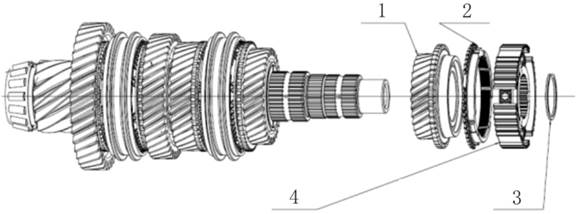

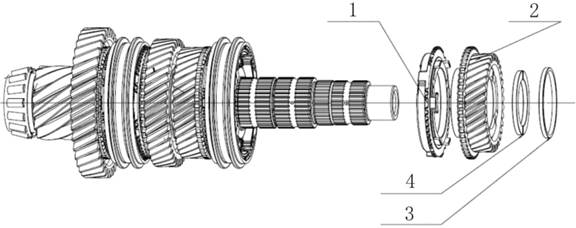

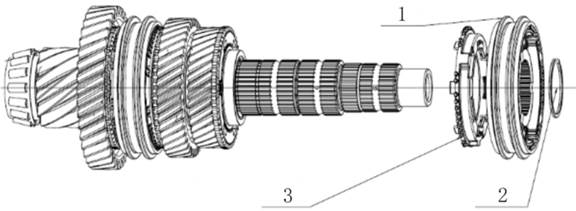

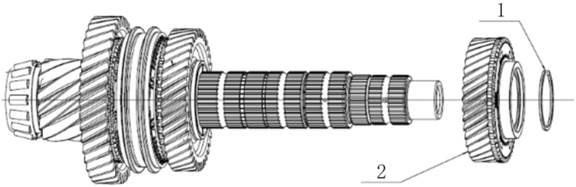

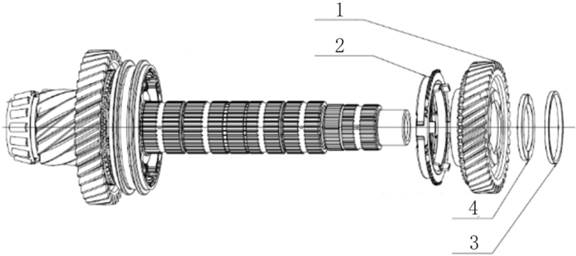

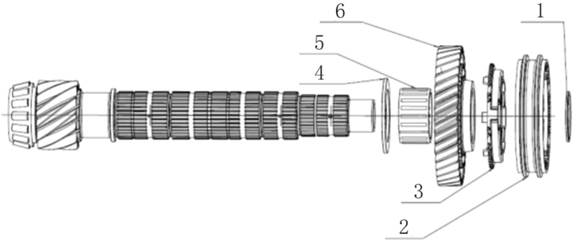

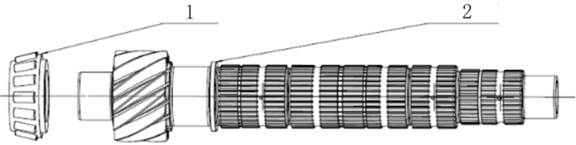

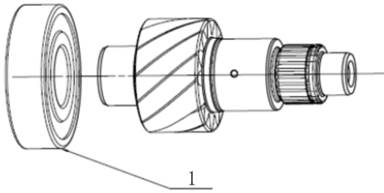

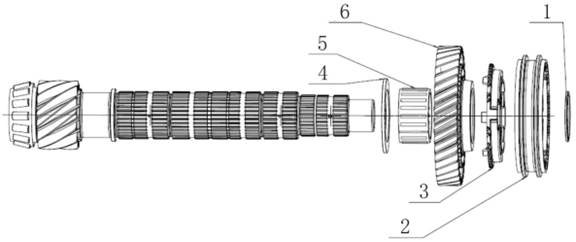

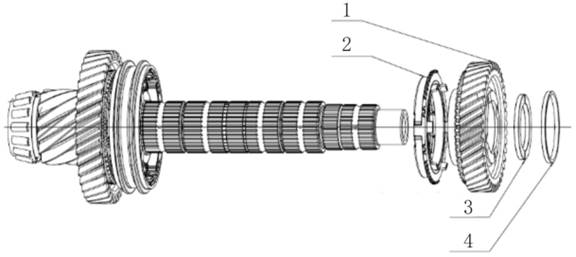

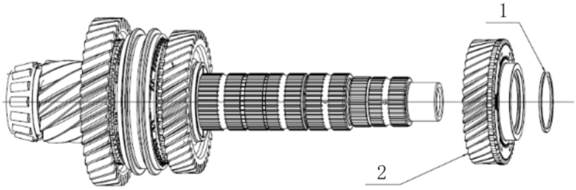

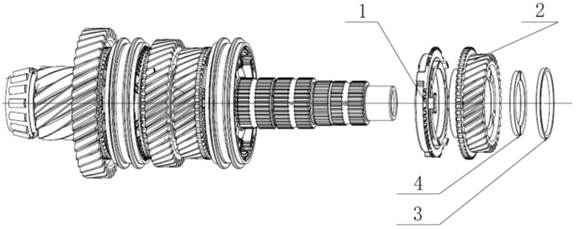

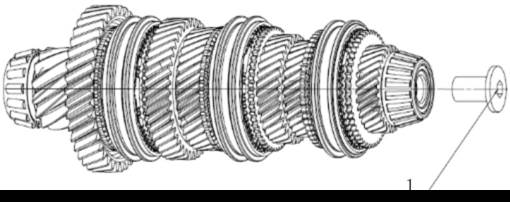

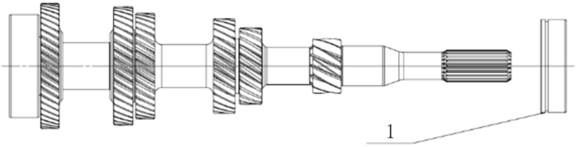

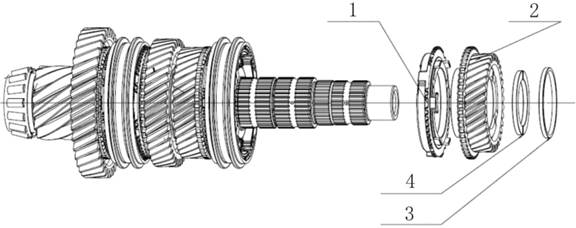

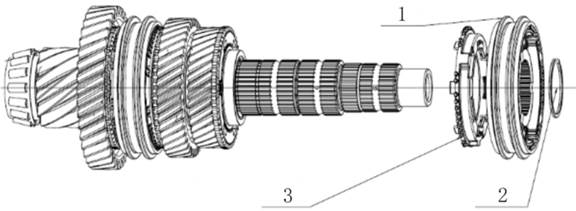

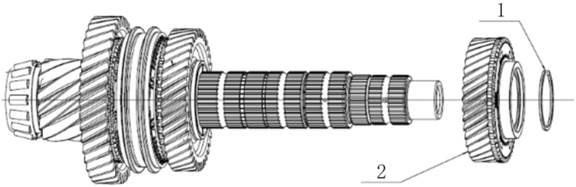

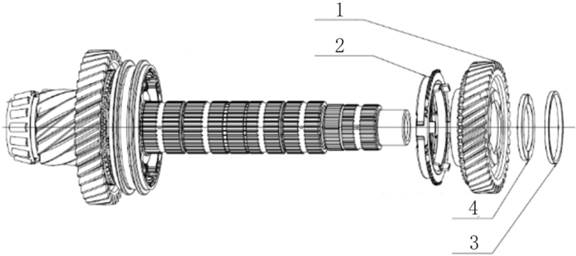

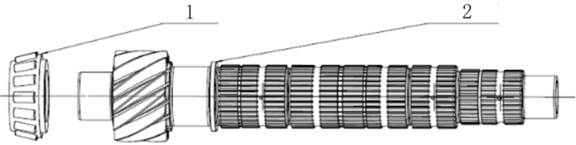

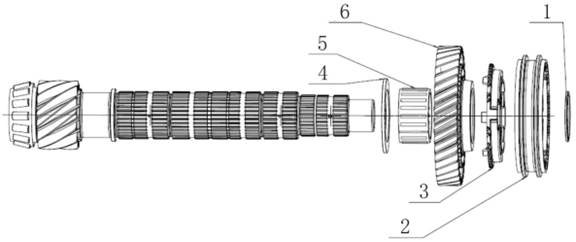

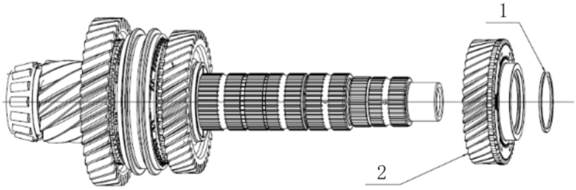

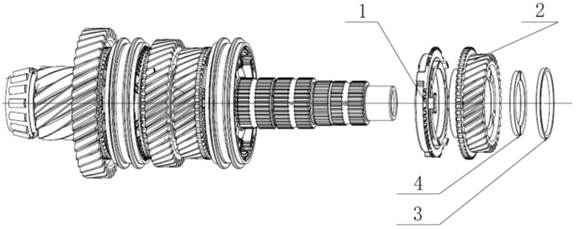

2.1.4 Countershaft

1. Steel

belt 2. Steel plate

The

countershaft (pinion shaft) decelerates the two meshed helical gears between

the driven cone and the differential, thus ensuring that the drive shaft

rotates in the correct direction. The deceleration between driven cone wheel

and driving shaft greatly improves vehicle performance. The countershaft is

fixed by two conical bearings located in the clutch housing and the independent

bearing housing.

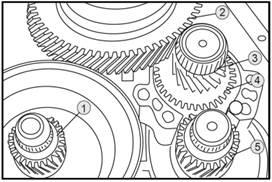

Gear

ring and intermediate gear

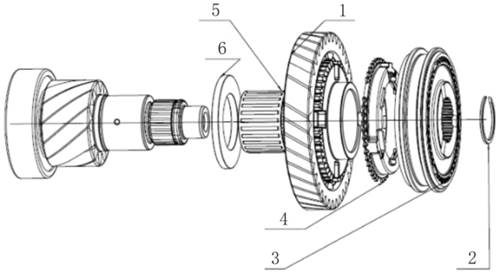

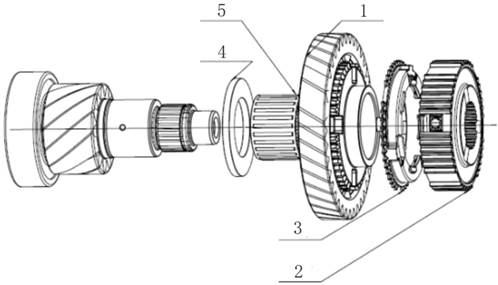

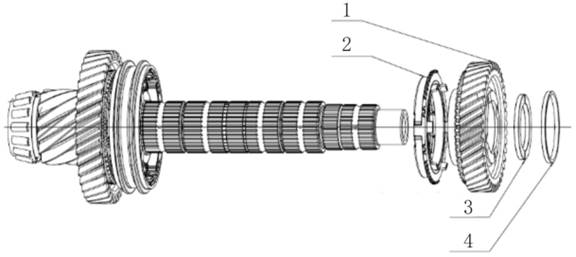

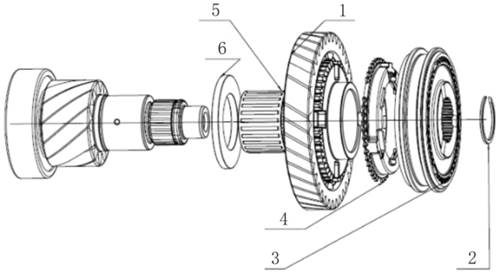

2.1.5 Differential

1.

Driving bevel shaft transmission gear

2.

Differential crow gear

3.

Transmission pinion

4.

Transmission intermediate gear

5.

Driven cone shaft gear

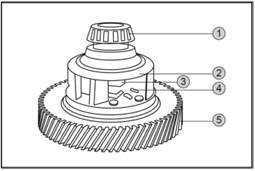

Like the manual transmission, the

torque on the crown wheel is transmitted to the wheels through the

differential, the crown wheel is bolted to the differential housing by eight

bolts, and the drive shaft is bolted to the differential by the traditional

ball-cage universal joint and gasket. Taper bearing is used to fix the

differential.

Differential assembly

1.

Differential bearing

2.

Differential shell

3.

Differential spider

4.

Differential planet gear

5. Differential

crow gear

2.1.6 Machinery

Operation

·

The transmission ratio number of traditional planetary automatic transmission

is limited, usually four, five or six; but the CVT is

different,

as the name suggests, CVT transmission ratio is continuous change. Low speed

gear (low transmission ratio) makes it easier for a stationary vehicle to

start. The diameter of the drive bevel gear is relatively small, but that of

the driven bevel gear is relatively large. The belt is used to transmit power

and torque. If the high-speed ratio is selected by increasing the diameter of

the drive bevel gear and reducing the diameter of the driven bevel gear, the

acceleration can be generated. Ensures optimum transmission ratio by controlling

the degree of variation.

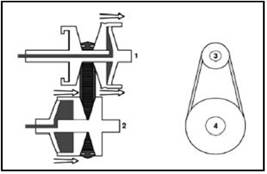

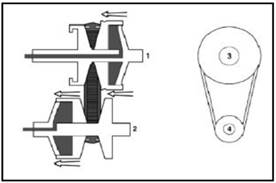

CVT

transmission has two rotating gears of drive bevel gear and driven bevel gear,

each bevel gear is composed of two halves, one half is fixed, the other half

can be moved by hydraulic control. The position of the belt on the runner

determines the transmission ratio. If the moving half wheel is close to the

corresponding fixed half wheel, then the belt will move towards its periphery.

When the two cone wheels are separated, the circumference of the wheel will

become smaller, and the moving half wheel of the active cone wheel and the

driven cone wheel are in their respective diagonal positions. At this time, the

radius of the driving belt on the active cone wheel reduces, while the radius

of the driving belt on the driven cone wheel increases.

A

low transmission ratio is required for a vehicle to start. For this reason, the

driving cone wheels are separated so that the belt is attached to it and the

belt moves around the closed driven cone wheel. When the vehicle speed

increases, a high transmission ratio is required. For this reason, the moving

half wheel of the active cone wheel gradually approaches the corresponding

fixed half wheel, and the wheel circumference of the cone wheel increases. At

the same time, the driven cone wheel is forced to separate, and the radius

decreases, resulting in a higher transmission ratio. When the driving cone

wheel is completely closed and the driven cone wheel is completely separated,

the transmission ratio of overdrive gear is produced. The drive and driven

bevel gear rotate at a transmission ratio of about 1:2.5.

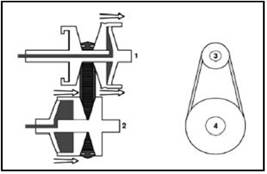

Belt

pulley position when in low gear

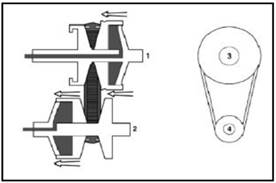

Belt

pulley position when in high gear

1.

Engine input

2.

Output to the wheels

3. Min diameter

driving wheel (low speed)

4.

Max diameter driven wheel (low speed)

1. Engine

input

2.

Output to the wheels

3.

Min diameter driving wheel Max diameter driven wheel

·

Gear selecting handle is in neutral or parking position

·

In this state, reversing clutch (2) and forward clutch (4) separates, can’t

make the wheel move.

- Transmission input shaft (1) and

engine speed are the same.

- Transmission input shaft (1) and

engine speed are the same.

-

Backward clutch (2) separates.

-

Forward clutch (4) separates.

-

Planet gear (3) idle running around sun gear

- Sun gear not move,

drive gear (5), driven gear (7) and the vehicle

also keep still.

For

all automatic transmissions, the engine can only be started in neutral or in

park gear. In parking gear, the mechanical lock prevents the vehicle from

moving back and forth. In order to avoid damage to the transmission, the

parking gear can only be used when the vehicle is not moving.

1. Input

shaft 5. Drive gear

2.

Backward clutch 6. Driven steel belt

3.

Planet gear 7. Driven bevel gear

4.

Forward clutch

· Gear selecting lever is in

forward gear, in this state, the forward clutch (4) engages to make the wheels

move.

· Gear selecting lever is in

forward gear, in this state, the forward clutch (4) engages to make the wheels

move.

-

Transmission input shaft (1) is the same with the engine speed.

-

Reversing clutch (2) separates.

-

Forward clutch (4) engages

-

Planet gear (3) of planet mechanism, sun gear and gear ring rotate together.

-

Drive gear (5) is the same with the engine speed, the direction is forward gear

direction.

- Driven gear (7) is the forward

gear direction, its speed depends on the transmission ratio in this running

state.

1.

Input shaft 6. Drive steel belt

2.

Reversing clutch 7. Driven cone shaft

3.

Planet gear 8. Driven bevel gear

4.

Forward clutch 9. Input shaft

5.

Drive bevel gear

· Gear

selecting lever is in reversing gear, in this state, backward clutch (2)

engages, gear ring (9) is locked in transmission housing. Planet gear (3) makes

the

rotating direction of sun gear

(10), drive gear (5) and driven gear (7) be opposite to the transmission input

shaft (1). Now reversing gear is selected.

-

Transmission input shaft (1) is the same with the engine speed.

- Reversing gear (2) separates.

- Reversing gear (2) separates.

-

Forward clutch (4) separates.

- Gear ring (9) connects to transmission

case through backward clutch (2).

- Direct transmitting planet gear

(3) of transmission input shaft (1) make it rotate around the gear ring, thus

drive the sun gear (10), belt gear

(5) and driven cone gear (7) rotate

backward.

1. Input

shaft 6. Drive steel belt

2.

Backward clutch 7. Driven cone shaft

3.

Planet gear 8. Driven bevel gear

4.

Forward clutch 9. Gear ring

5.

Drive cone gear 10. Sun gear

2.2 Control System

The

functions of control system are as follows:

1.

Make the clamping force of the steel transmission belt tension adapt to the

engine torque to prevent the belt from slipping.

2.

Control the forward clutch and the backward clutch while driving.

3.

Provide the best transmission ratio for driving.

4.

Provide the necessary lubricating oil and cooling oil for the transmission.

2.2.1

Oil Pump

The

oil pump in the transmission is the external engaging gear pump. The engine

drives the oil pump shaft, which reaches the inside of the oil pump through the

hollow drive bevel gear shaft. The pump shaft is splined to the planetary gear

rack. The pump shaft has been running at the engine speed. The pump oil is

about 10cm³. System pressure up to 40~50bar

depending on input torque.

Oil

pressure is not only used for hydraulic control of the transmission, but also

for lubrication.

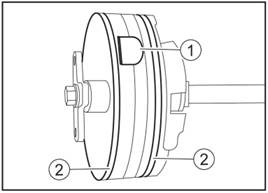

Oil

pump full figure

1. Oil

pump drive shaft 2. Oil pump assembly

Oil

pump inlet

1. Oil

pump inlet 2. Oil pump seal

2.2.2 Transmission

Control Device

The

transmission control device minimizes the tension between the belt and the

runner without slipping, and also provides the transmission ratio based on the

target values given by the driving strategy (calculated based on the input

(drive) and output (driven) speeds of the transmission). During the service

life, the performance degradation of the control device will be kept within a

certain range without obvious impact on vehicle comfort and belt tension.

2.2.3 Tension Control

Device

The tension control

device can obtain the required minimum tension force when the belt is not

slipping, which has the least impact on the transmission transmission

efficiency and the lowest fuel consumption.

In addition to normal

driving, the tension control device also takes into account the special

circumstances of transmission torque maximum input and output, so as to

maximize the protection of the transmission. The control device takes into account

anti-lock braking system (ABS), tire lock (no ABS) and other driving force

control system (such as ESP, anti-slipping control device, etc.). In addition,

the device also takes into account special roads and

conditions, such as passing through pot-holed road, road shoulder,

high and low adhesion coefficient transition, and tire slip (such as on low

adhesion coefficient road). The software can compare the transmission

performance of the transmission torque with the expected input torque of the

transmission. When the tension control device finds that the tension force is

insufficient, the ECU receives the instruction to reduce the torque, so as to

adjust the engine torque within the appropriate range. This function also

protects

the

transmission.

If there is no electronic drive circuit system in the

vehicle, the ECU transmits the torque signal through the CAN bus. If there is

no CAN bus, the transmission control system (TCU) software itself generates the

default torque signal.

2.2.4 Speed Ratio

Control Device

The transmission

controls the transmission ratio by controlling the input and output pressure to

balance the pressure on the drive and driven bevel gear. The transmission ratio

can be calculated according to the speed sensor signals of the drive bevel gear

and the driven bevel gear, and the required transmission ratio can be obtained

by changing the output pressure. The minimum pressure can be determined by the

tensioning method. The physical model of the transmission helps to quickly

adjust the pressure level to the variable operating point. The control software

also considers the interference from other components of the transmission, so

it was developed to minimize delay errors and target speed ratio errors as

possible(to improve fuel economy).

In

order to meet the requirements of transmission machinery and durability limit

state, we developed some driving strategies in limit state. In addition to the

speed limit, the rate of change of the transmission ratio (the set point) is within

the allowable range through the software. In addition, the software also

prevents the engine speed from exceeding a certain limit due to the vehicle

speed and the condition of the gear lever (POS). To achieve this limitation,

the software will require a reduction in engine torque or a shift of the

vehicle into higher gear.

2.2.5 Transmission

Control Unit

The

software controls transmission is integrated in TCU (Transmission Control

Unit). TCU is installed inside the cab.

2.3

External Device

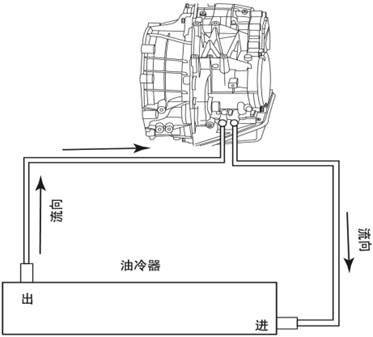

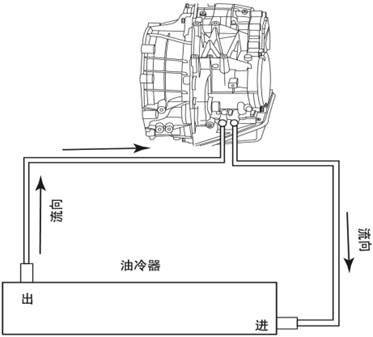

2.3.1 Oil Cooler

Connector

There

are two oil cooler pipes in front of the transmission housing. The inlet of one

oil cooler is installed next to the engine radiator, to keep the temperature of

the lubricating oil below 120 °C. The oil in the transmission flows out from

the right port, which should be connected to the lower port of the oil cooler.

The

oil of the oil cooler enters into the transmission from the port on the left

side of the transmission, so the port on the left side of the transmission

should be connected to the upper port of the oil cooler.

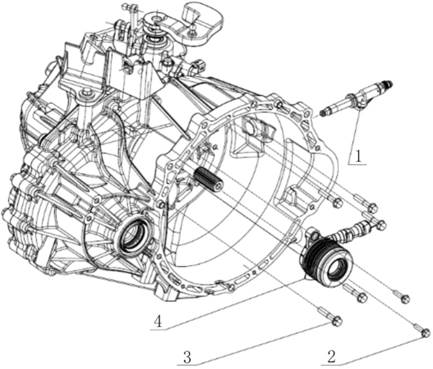

2.3.2 Shift lever

Oil

cooler pipe connector

The gear position of

VT3 transmission may include stop gear (P), reverse gear (R), neutral gear (N),

forward gear (D), and sport mode (S).

Customer can customize

the configuration of the shift lever. For the sake of safety, it is recommended

to apply gear shift locking device as starting protection.

CVT transmission can

also achieve manual mode, which requires the addition of new pins on the TCU to

receive signals, and the calibration of the maximum speed of the engine within

a certain range. All JAC CVT transmissions have manual mode.

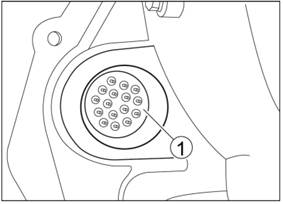

2.3.3

Main Connector

Main connector is on

transmission housing, includes 16 pins. The wiring harness connects through

circular connector.

2.3.4 Torsional shock

absorber

Most conventional

automatic transmissions use a torque converter to connect the engine to the

input shaft, but this one uses a torsional shock absorber.

3.General Information

3.1

Towing Vehicle

Vehicle equipped with

VT2 or VT3 transmission cannot be directly towed, because only when the engine

is running, oil pressure can be generated in the cone wheels and the

transmission belt can run. Therefore, the front wheel must be lifted from the

ground when towing.

3.2

Maintenance Period

Every 60,000km or two

years (whichever is the first), the transmission oil and oil filter must be

replaced. Therefore, the transmission is equipped with oil drain plug and

refueling screw plug. Vehicle manufacturer can reduce the transmission

maintenance period, so that it can match the vehicle’s standard maintenance

period.

3.3

Lubricant Oil Specification

Please use MOBIL(ESSO)

EZL799(A) or IDEMITSU CVTF-EX1, the two types oil can be mixed, but it’s not

advised.

The use of other oil

may result in damage to the interior of the gearbox. Once other oil is used,

this gearbox cannot be claimed.

3.4

CNG (Compressed Natural Gas), LPG (Liquefied Petroleum Gas) etc

Risks

of switching to CNG:

--

the vehicle will have a different or unstable torque diagram, which will result

in:

•

different performance

•

very poor driving response

•

generate fault codes

•

clutch movement problem

•

self-learning problems

•

steel belt slips

PUNCH does not allow vehicles to be

changed to other fuel systems: CNG, LPG,...PUNCH immediately discontinued this

gearbox warranty as soon as the vehicle was fitted with another fuel system.

4.

Technical Parameter/Maintenance Parameter

|

No.

|

Project

|

Parameter

|

|

1

|

Transmission

|

VT3

|

|

2

|

Type

of lubricant oil

|

MOBIL(ESSO) EZL799(A)/DEMISTU

CVTF-EX1

|

5. Torque parameters

|

No.

|

Project

|

Tightening Torque (N · m)

|

|

1

|

Oil

filler plug

|

21±3

|

|

2

|

Driven bevel wheel shaft end cover

countersunk screw

|

9.5±0.95

|

|

3

|

Drive cone gear shaft nut

|

197.5±17.5

|

|

4

|

Oil

pump bolt

|

10±1

|

|

5

|

Driven bevel gear shaft end cover bolt

|

9.5±2.5

|

|

6

|

Oil

pan bolt

|

9±1

|

|

7

|

Speed sensor fixing bolt

|

8.5±2

|

|

8

|

Speed sensor bracket fixing screw in

differential

|

9.5±0.95

|

|

9

|

Valve

bolt

|

11±1

|

|

10

|

Oil

drain screw plug

|

11±1

|

|

11

|

Driving mode sensor fixing screw

|

9.5±0.95

|

|

12

|

Oil

level screw plug

|

15±2.25

|

|

13

|

Gear shifting handle nut

|

14.5±1.5

|

6.

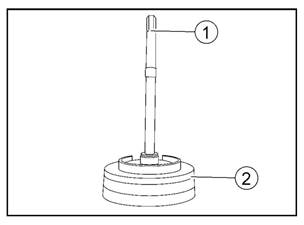

Special Tool

|

No.

|

Tool No.

|

Tool name

|

Tool

illustration

|

Usage

|

|

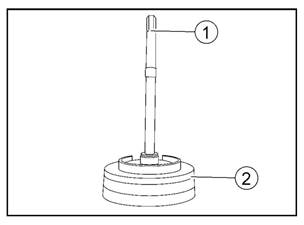

1

|

16G0049

|

Drive

bevel gear shaft bearing plug

|

|

Remove the drive bevel gear bearing

|

|

2

|

16G0043

|

Assembly

tool of gear shift shaft oil seal

|

|

Install gear select

shaft oil sealing

|

|

3

|

16G0050

|

Drive

bevel gear shaft bearing punch

|

|

Install

the drive bevel gear shaft ball bearing

|

|

4

|

16G0048

|

Drive bevel gear

shaft bearing removal tool

|

|

Remove the drive

bevel gear shaft ball bearing

|

|

5

|

16G0041

|

Assembly tool of

input shaft oil seal

|

|

Install the input shaft oil seal

|

|

6

|

16G0040

|

Input shaft oil

seal locating bushing

|

|

Install the input shaft oil seal

|

|

No.

|

Tool No.

|

Tool name

|

Tool

illustration

|

Usage

|

|

7

|

16G0042

|

Disassembly tool

of gear shift shaft oil seal

|

|

Remove the gear select shaft oil sealing

|

|

8

|

16G0046

|

Locating pin of

hydraulic control module

|

|

Install the

hydraulic control block

|

|

9

|

16G0038

|

Differential oil

seal installation tool

|

|

Install the

differential oil seal

|

|

10

|

16G0045

|

Oil pump removal tool

|

|

Remove the oil pump

|

|

11

|

16G0044

|

Air pipe assembly tool

|

|

Install the respirator hose

|

|

12

|

CVT-HDFJ-1

|

N gear

installation auxiliary tool

|

|

Limit the

transmission gear shift rocker arm position

|

Chapter II Driving

strategy

1. Function Characteristic

of Parking and Neutral Gear

No matter what kind of

transmission, the engine can only be started in the parking and neutral state.

The mechanical lock in the parking gear prevents the vehicle from moving back

and forth. Had better be in vehicle static condition uses parking gear, in case

injury transmission.

If

you accidentally use the parking gear when the speed is high, the parking

device can only work if the speed is reduced to about 5km/h.

1.1

Parking Locking Mechanism

When the vehicle starts

up, TCU will control the starting relay, and the starting relay can control to

start the engine. The vehicle's gear is controlled by an internal driving mode

sensor, which is connected directly to the gearshift lever. To shift parking

(P) or neutral (N) to drive (D) or reverse (R), the brake pedal is pressed. If

the brake pedal is not pressed, the gear lever remains locked in either P or N.

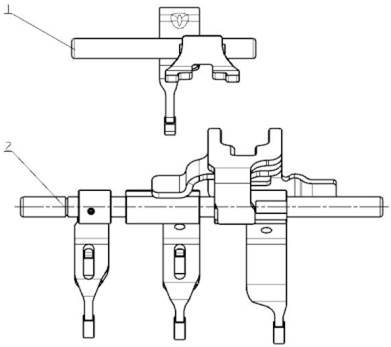

Parking lock mechanism

1.2

Function of D/R Gear

1.2.1 General

operation

1.

Parking stop pawl 2. Driven cone wheel

When

driving, the operation of this transmission is completely different from that

of traditional automatic transmission, so you should pay attention to adapt.

Example: If you press the accelerator pedal too hard, the engine speed will

increase obviously, but the speed will not change much. This feature is normal

for CVT transmission, but if the driver does not know about the transmission,

it may be mistaken for a faulty gearbox.

Other

analogies to traditional automatic transmissions may also exist.

1.2.2

Self-adaption updating

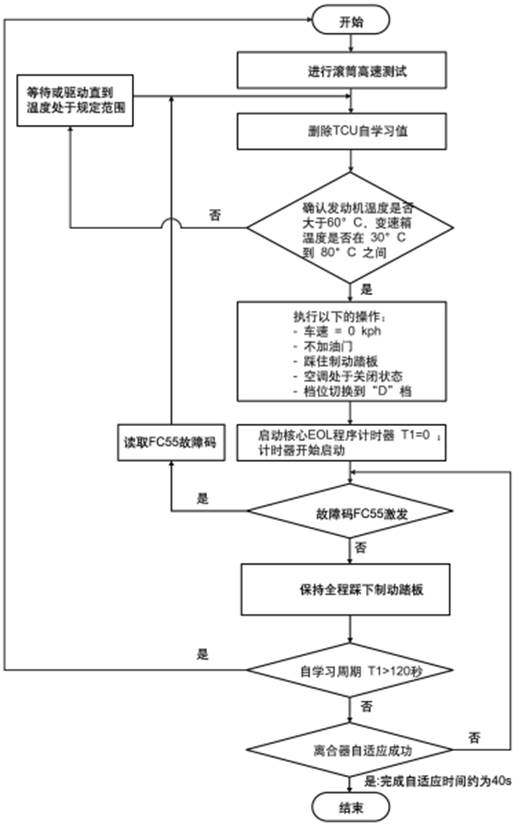

Whether

forward or reverse, the corresponding clutch should be calibrated again to

achieve the best effect in its service life.

1.2.3 Creep

According

to the performance of automatic transmission, when the shift lever is in

forward gear (D) or reverse gear (R), if the driver releases the brake pedal,

the vehicle will start crawling (flat road). If the road slope is less than 8

°, the vehicle also can crawl; If the road slope is greater than 8 °, the

vehicle will be slightly backward, which is the same with the vehicle equipped

with hydraulic torque transmission, it will not backward if the slope degree is

not large. Regardless of the slope of the road, the maximum speed at which the

vehicle climb will be less than a limit (8kph). Especially downhill, the

control system will allow the clutch to switch from separation to

"engage" mode, allowing the engine to brake during the glide.

1.2.4 Idling parking

(only for D gear state)

The

VT3 transmission can idle stop. The vehicle (battery status, A/C ON/OFF) and

the transmission (without affecting the transmission durability) can idle stop

under certain conditions. If all conditions are met, the internal combustion

engine can stop at rest. Only when the brake pedal is released and the engine

starts up again and the transmission works quickly can the vehicle move forward

and backward.

The

idle stop feature is particularly useful for hybrid drives, but is useless for

standard drives without a special starter or starter motor.

1.2.5 Acceleration and

deceleration

The

acceleration process mainly provides acceleration according to the driver's

requirements and driving conditions. At this time, the change trend of engine

speed corresponds to the initial speed, so as to achieve the best driving

comfort.

The

clutch controller also provides some means of compensating for the difference

in clutch wear (it differs between different vehicles) to ensure driving comfort.

1.2.6 Acceleration

support

In

order to achieve optimal driving comfort, it is necessary to determine the most

appropriate engine speed, which is between the minimum traction engine speed

and the engine speed when the vehicle maintains a constant speed (economic

speed) cruise state.

The

transmission control system provides functionality to meet these requirements

by using a combined control mode between the transmission (ratio control) and

the starting clutch. Therefore, when the vehicle starts, the control target is

always focused on the driving performance of the higher engine speed related to

the acceleration of the vehicle, while when the vehicle cruises or glides, the

control target is transferred to the fuel economy of the transmission system.

1.2.7 Deceleration

If

the driver presses the brake pedal at the same time as the accelerator pedal,

the engine speed will be limited to a certain range (similar to the torque

converter). Therefore, the gearbox needs to be combined with the engine control

system to block torque so that the gearbox can react quickly to the driver's sudden release of the

brake pedal and start to control the clutch. Long-term use will cause high

temperature loss of the clutch, the transmission also has the risk of damage,

so we use the monitoring function to

detect

these dangerous conditions. Activate the transmission's internal diagnostic

system to open the clutch. If the driver keeps his foot on the gas pedal, the

engine will rise up to its maximum speed. In addition, the clutch controller

can also follow the highest control goal in other cases, to ensure the original

safety and improve the driving comfort.

1.2.8 Driving and brake

When the vehicle

decerates to stop, the clutch is separated again to prevent the engine from

stopping. The clutch pressure is controlled to drop steadily to gradually

separate the clutch, so as not to cause torque fluctuations. Therefore, the

controller provides different modes according to the change of speed to

separate the clutch. The clutch pressure control also controls the power of the

hydraulic control system according to the oil temperature of the transmission.

The clutch can be quickly ready to start after separation.

In

order to make the driving comfort optimal during the vehicle braking and

starting process, the transmission software and other transmission control

device work together, this role makes the torque transmission temporarily

interrupted, idle speed increase.

1.2.9 Clutch combines/separates when driving

If

the clutch is not used while driving, the transmission controller has little

effect on the comfort of driving, as the absence of the clutch has nothing to

do with the characteristics of the hydraulic system. In such case (low load,

stopping, low engine speed), the driving comfort may be reduced when the clutch

is applied again compared with when the clutch is applied in the stationary

state.

1.3 Failure Default Mode

When

the software detects a system error, the default rule is applied.This is

transmitted to the drive through the instrument group's fault display. The

driver will take a different default driver state depending on the severity of

the error. In some cases, the main relay will be turned on. All fault codes

will appear on the OBD.

1. Transmission Oil

1.1

Special Tool (No)

1.1.1 Oil level check

instruction

Chapter

III Usage Instruction

The

following oil level check should be carried out whenever draining the

transmission oil or replacing new transmission. There is no oil in the

transmission as service part, and after being installed on the vehicle, it need

to add 4.5±0.05L ESSO EZL799(A) or

Idemistu CVTF-EX1 oil, please add

oil and check the oil level according to the following methods. 1. Shift the

operation lever to P gear position.

2.

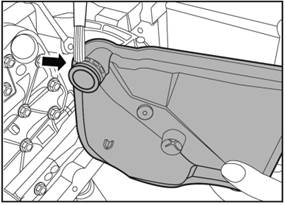

Remove the oil filling plug (3) on the top.

3.

Ensure that the oil drain plug (1) is assembled.

4.

Fill 4.5±0.05 L transmission oil Esso EZL 799A to the transmission oil from the

oil filling plug (3) on the top.

5.

Reinstall the oil filling plug (3). Tightening torque (M14) : 21N·m.

6.

Step the brake pedal.

7.

Start the engine.

8.

Run the engine for 10 seconds.

9.

Shift the shift lever away from P gear position.

10.

Note: the sound of air circulating through the system may be heard at the

initial start-up. This is normal operation.

11.

Switch the operation lever to each gear (P-R-N-D) and remain in each gear for 5

seconds before switching to the next gear.

12.

Shift the operation lever to D gear position.

13.

Release the brake pedal.

14.

Step lightly on the accelerator pedal to 60km/h (engine speed must not be

higher than 2500rpm).

15.

Release the accelerator pedal and tap the brake brake until the vehicle stops.

16.

The above two steps should be performed at least twice.

17.

Driving around at least 5 minutes (hope temperature rises from 30 ℃ to 50 ℃).

18.

Step the brake pedal.

19.

Wait for 2 seconds.

20.

Shift the operation lever to R gear position.

21.

Release the brake pedal.

22.

Wait for 10 seconds.

23. Step the brake pedal.

24.

Wait for 2 seconds.

25.

Shift the operation lever to N gear position.

26.

Keep the engine idling.

27.

The engine must be running and the lever must be in N gear.

28.

Check the oil temperature: must be between 30 ℃ to 50 ℃.

29.

Wait 2 minutes until oil level stabilizes.

30.

Remove the oil level plug (2) (the engine is still running).

31.

Wait a few minutes until the oil drips off from the oil level plug.

32.

Reinstall the oil level plug.

33.

Tighten oil level plug (tightening torque (M14) : 21N·m).

34.

Stop the engine and shift the lever to P gear position.

1.2

Oil Level Inspection

If the initial oil

filling is correct, the oil level should be in the correct position (oil level

bolt position). Normal allowrance (such as new transmission residual oil and

production line fueling allowrance) should be oil level bolt position, oil

level can be ±0.165L.

1.

Check the oil level of the transmission

1)

Remove the oil filling bolt on the upper end of the transmission.

2)

Add accurate 0.5L±0.05L oil to the transmission.

3)

Install the oil filling screw plug. Tightening torque 18~4N·m.

4)

Starting the engine to make transmission temperature rising to about 60 ℃.

5)

Place the vehicle on the flat ground.

6)

Press the brake pedal, and wait 2 seconds, and then shift to P gear position.

7)

Keep the engine idling running.

8)

Remove the oil level inspection bolt when the engine is idling.

9)

Release the oil accurately (0.335L at least, 0.665L at most)

Min of 0.235L (0.5

ADDED oil-0.165 tolerances - 0.1L = 0.235L) oil will flow from the gearbox, and

if less than that, the original oil level is too low.

Max of 0.565L (0.5 ADDED

oil+ 0.165 tolerances - 0.1L = 0.565L) oil will flow from the transmission, and

if less than that, the original oil level is too high.

▲Note:

All data comes from when the transmission oil temperature is 60 ℃.

10)

Install new gaskets and tighten oil level bolts. Tightening torque 18~24N·m

11)

Stop the engine.

Oil

draining bolt (1) Oil level bolt (2)

Oil filling screw plug (3)

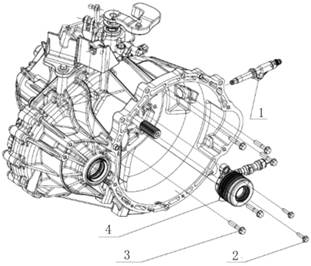

2.

Disassembly and Assembly of Shift Control Mechanism System Component and Pull

Cable Adjusting Method

2.1.

Special tool

|

1

|

CVT-HDFJ-1

|

N gear installation auxiliary tool

|

|

2.2 Gear Shift Pull Rode Assembly

This procedure

describes how to correctly connect the gearshift lever. Failure to follow this

instruction may result in transmission gear disorder. The dashboard will always

show the transmission gear status regardless of the gear lever position. A

precise

shift wire drawing installation

allows the instrument panel and shift lever to indicate the same shift status

(PRND). If replacing the gear shift control mechanism, select &shift gear

pull cable, pull cable bracket, shift rocker arm and sleeve, pull rod assembly,

transmission

or other

components that affect the transmission gear shifting operation control, they

must be re-adjusted, otherwise there will be a shift disorder or even cause the

vehicle can not run and other faults. The removal and adjusting method are as

shown below:

2.2.1 Disassembly and Assembly of

Shift Control Mechanism System Component

1) Replace pull cable bracket,

first loosen the gear shift&select pull cable and shift rocker arm, make the

pull cable

1) Replace pull cable bracket,

first loosen the gear shift&select pull cable and shift rocker arm, make the

pull cable

Separate from

the rocker arm, and separate the pull cable from pull cable bracket, and then

replace the pull cable bracket. Assembly of pull cable:

2)

Replace gear shift rocker arm and shift rod

▲Note: ① Consider the

operating space, before replacing the "gear select&shift pull cable

assembly", put the shift lever to the P gear position, and then take down

the pull cable and

transmission

control mechanism connection end, but put the shift lever to the P gear

position again before installing the pull cable. ② Before replacing the other

parts, must ensure that the gear shift control mechanism gear lever in the P

gear position; ③ Connect the gear select&shift pull cable to the

transmission gear select rocker arm by bolts and nuts (when tightening the

nuts, must not bend the transmission gear shift rocker arm or pull cable).

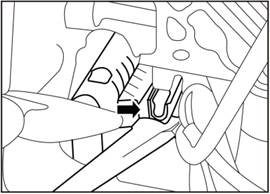

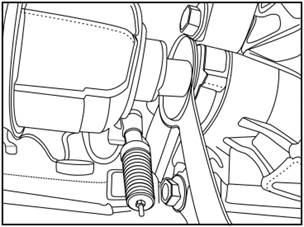

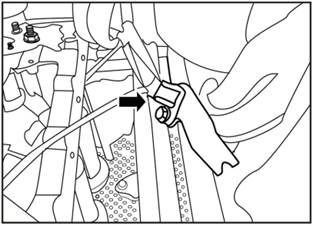

A. Disconnect the gear

select&shift pull cable and the gear shift rocker arm.

A. Disconnect the gear

select&shift pull cable and the gear shift rocker arm.

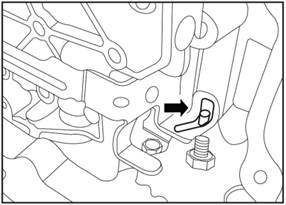

B. Loosen the rocker arm fixing

bolt Q1840830F61 (pay attention to the rocker arm sleeve)

C.

Loosen the transmission end pull rod fixing nut Q32008F61L D.Disconnect the

gear select rocker arm and gear select pull rod

E.

Connect the gear shift rocker arm and gear shift pull cable ball

F.

Tighten the gear shift rocker arm and transmission

(Q1840830F61),

tightening torque:20~28Nm

G.

Shift gear forward and backward, relieve stress, and shift to P gear position

at last

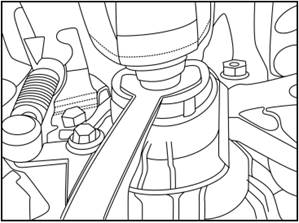

H.

When the gear shift pull rod is fixed connected to the transmission, the gear

shift pull rod lock is unlocked. Pay attention to the control mechanism and

transmission swing arm in P gear position, tighten the nut Q32008F61L in P gear

position, the tightening torque is 20~28Nm, and finally press the gear shift

pull rod lock to lock the pull rod.

Ball

joint decorative ring

|

|

3) Replace the gear select &

shift pull cable assembly

3) Replace the gear select &

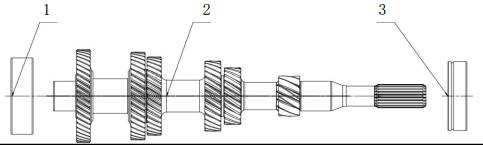

shift pull cable assembly

Auxiliary

dashboard assembly

|

|

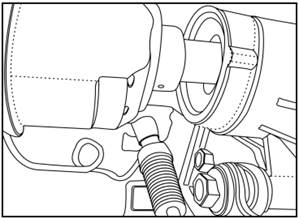

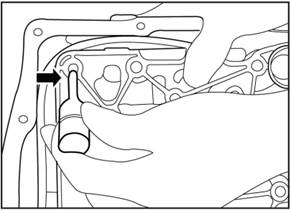

a—Put the gear

shift lever to the N gear position, remove the protective guard (the protective

guard is connected to the auxiliary dashboard by buckles), and clockwisely

rotate the gear select&shift ball joint decorative ring. After the

decorative ring is shaken, pull out the gear select& shift ball joint with

force.

b—Remove

the auxiliary dashboard

c—Disconnect

the pull cable and operating mechanism

d—Loosen

the 2 M8 nuts on the vehicle body (Q32008F61)

e—Disconnect the pull cable and the

gear shift rocker arm

e—Disconnect the pull cable and the

gear shift rocker arm

Ball

joint decorative ring

|

|

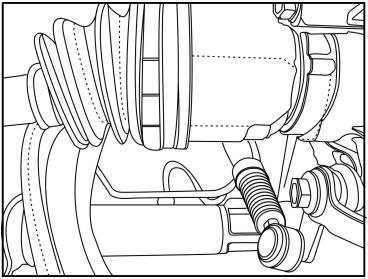

f—Disconnect

the pull cable and transmission with rear suspension

g—Pass

the new gear select&shift pull cable assembly into the cabin through the

engine compartment.

Auxiliary

dashboard assembly

|

|

h—Tighten the 2

M8 nuts (Q32008) on the front wall of the vehicle body Tightening torque is

20~28Nm

i—Connect the cable joint (at

transmission control mechanism end) to the pin shaft of the transmission

control mechanism.

j—Install the pull cable damper in place

j—Install the pull cable damper in place

k—Install

the pull cable and suspension bracket in place.

1—Install

the pull cable and rocker arm in place.

1)

Replace the shift control mechanism assembly

—Put

the shift lever to P gear position, and operate according to the pull cable

maintenance steps a-b-c

—After finish step c, remove the 4

fixing bolts Q146B0830TF38, and take down the shift control mechanism

—Install the gear shift control

mechanism tightening torque is 20~28Nm

—Connect

the cable joint (at transmission control mechanism end) to the pin shaft of the

transmission control mechanism.

—Install

the pull cable damper in place

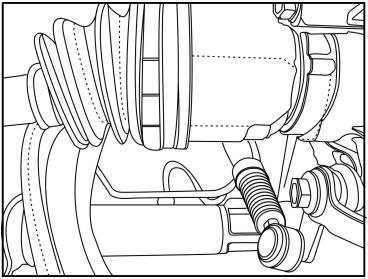

3.

Half shaft

3.1

installment

When

installing the half-shaft to the full transmission, we strongly recommend using

PUNCH 480145 tool to protect the differential oil seal. If the differential

shaft is damaged, the transmission will inevitably leak oil. Using special tool

will significantly reduce the chance of oil seal damage.

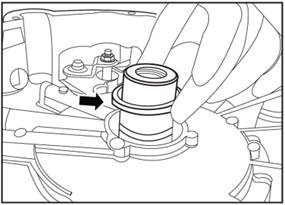

1)

Remove the oil seal protective cover.

2)

Install the tool on the half-shaft oil seal and install it well.

3)

Put the half-shaft into the transmission at a maximum depth of 4cm.

4)

Put the half-shaft into the transmission at a maximum depth of 4cm, with a

distance of 2cm between the half-transmission and the tool.

5) Take

down the tool

4)

Fully push the half shaft into the transmission, and the installation of half

shaft finished.

4. Differential oil seal

4.1

Fault code instruction

There

is oil seal damage or oil leakage, half shaft damage or oil leakage.

4.2 Special tool

|

1

|

480143

|

Differential oil

seal installation tool

|

|

4.3 disassemble

1. Discharge the transmission oil.

1. Discharge the transmission oil.

2.

Remove the half shaft. Refer to the drive shaft.

3.

Remove the differential oil seal.

1)

Use large flat screwdriver to pry out the oil seal.

▲Note: Be careful not

to put the flat screwdriver too deep to protect the shell.

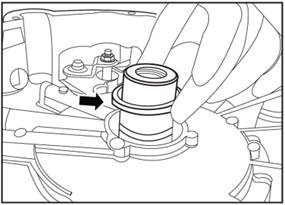

4.4

installment

1.

Install the differential oil seal

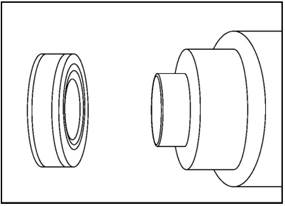

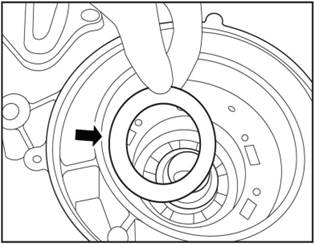

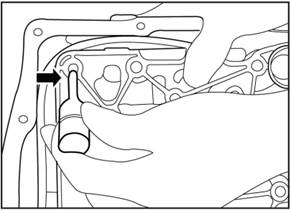

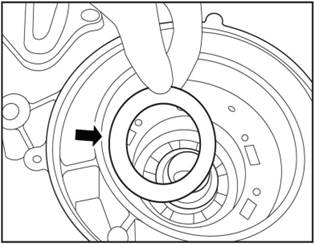

1)

Put the new oil seal to the shell.

2) Put the special tool 16G0038 on

the oil seal and hammer it into the shell with rubber hammer to ensure the

installation in place.

2) Put the special tool 16G0038 on

the oil seal and hammer it into the shell with rubber hammer to ensure the

installation in place.

▲Note: The depth of the oil seal should

be 3mm±0.3mm from the shell edge.

2.

Install the half shaft.

3. Fill

the transmission oil.

5.Input shaft oil seal

5.1 Fault

code instruction

Input

shaft oil seal damage or oil leak.

5.2

Special tool

|

No.

|

Tool No.

|

Tool name

|

Tool

illustration

|

|

1

|

16G0041

|

Assembly tool of

input shaft oil seal

|

|

|

2

|

16G0040

|

Input shaft oil

seal locating bushing

|

|

5.3 disassemble

1. Discharge the transmission oil.

1. Discharge the transmission oil.

2. Remove the transmission assembly. Refer to the

transmission assembly.

3. Remove the input shaft oil seal.

1)

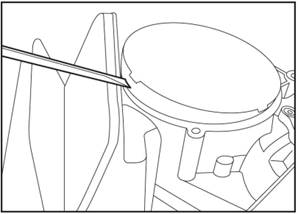

Remove the oil seal from the shell with large flat screwdriver.

▲Note: Pry along the

middle of the oil seal to the outside, must be very careful, or it will damage

the transmission input shaft.

5.4 installment

5.4 installment

1.

Install the input shaft oil seal.

1) Place the oil seal

locating bushing 16G0040 on the input shaft.

2) Place the new oil seal on

the locating bushing.

3) Put the special tool 16G0041 on

the input shaft, hit the special tool with a rubber hammer and install it in

place.

3) Put the special tool 16G0041 on

the input shaft, hit the special tool with a rubber hammer and install it in

place.

2.

Install the transmission.

3. Fill the transmission oil.

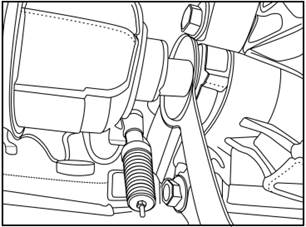

6.

Gear select shaft oil sealing

6.1 Fault

code instruction

Gear

select shaft oil sealing leaks oil.

6.2

Special tool

|

No.

|

Tool

No.

|

Tool name

|

Tool

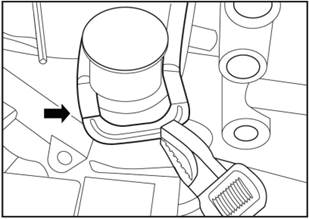

illustration

|

|

1

|

16G0043

|

Assembly tool of

gear shift shaft oil seal

|

|

|

2

|

16G0042

|

Disassembly tool

of gear shift shaft oil seal

|

|

6.3disassemble

1.

Discharge the transmission oil.

2.

Remove the transmission.

3. Remove the gear select shaft

lever.

3. Remove the gear select shaft

lever.

4.

Remove the gear select shaft oil seal.

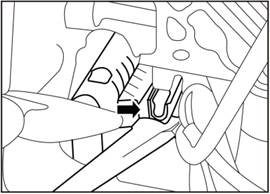

1) Put the

special tool 16G0042 on the shift shaft, and screw the special tool into the

oil seal with wrench.

▲Note: Press the top of the wrench

so that special tool screw into the oil seal.

2)

Turn the bolt on the special tool with the tool to pull the gear select shaft

oil seal out of the shell.

3)

Rotate the small bolt to pull out the oil seal.

4) Take out the oil seal.

6.4

installment

1.

Install the gear select shaft oil seal.

1)

Apply vaseline or lubricating grease to the tip of the oil seal punch 16G0043.

2)

Install the new oil seal lightly on the punch 16G0043.

3) Put the special punch 16G0043

with oil seal on the gear shift shaft and tap with a hammer until it is

installed in place.

4) Take out the punch 16G0043.

4) Take out the punch 16G0043.

▲Note: Rotate and pull

the punch out, or else it may cause the oil seal and the punch be pulled out

together.

2.

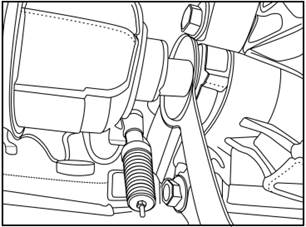

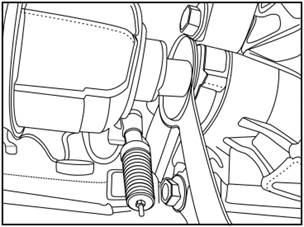

Install the gear select lever, and tighten the nut with new washer and nut,

torque 14.5N·m±5N·m.

3.

Install the transmission.

4. Fill the transmission oil.

7. Drive Bevel Gear End Cover

7.1

Fault code instruction

Drive

bevel gear end cover leaks oil

7.2

disassemble

1.

Dischrage about 1L oil from the transmission (see replacing the oil filter).

2. The

transmission does not need to be removed from the vehicle. It is easier to

replace the engine and transmission if they are placed together.

3.

Remove the bolt and remove the clasp. Remove the cover with a larger flat

screwdriver, and place a cloth pad under it to prevent damage to the

transmission housing.

4.

Remove the end cover with a larger flat screwdriver and put a piece of cloth

under it to prevent damage to the ring transmission housing.

5.

Remove the larger type O-ring and throw it away with the end cover.

7.3

installment

1.

Install a new O-ring.

2. Replace a new end cover and

tighten the bolt and buckle. Torque: 9.5N·m±2.5N·m.

3.

Fill 1L oil into the transmission.

8.

Oil Pump

8.1

Fault code instruction

If

the transmission pressure is found to be too low or the driving process

vibration or abnormal phenomenon, there are two important components can cause

this problem: oil pump and hydraulic control block. Use the fault code to

determine which one needs to be replaced. In most cases it is not completely

clear which one is the problem, just replace one by one to see whether the

problem is solved.

8.2

Special tool

|

No.

|

Tool No.

|

Tool name

|

Tool

illustration

|

|

1

|

480141

|

Oil pump removal

tool

|

|

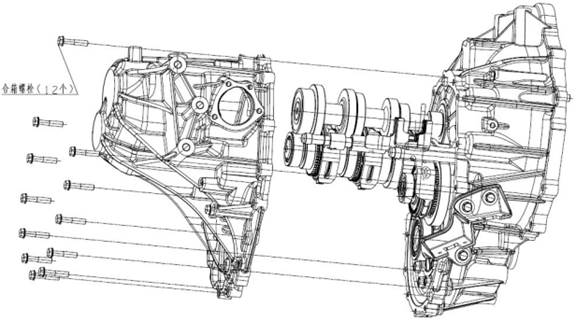

8.3 disassemble

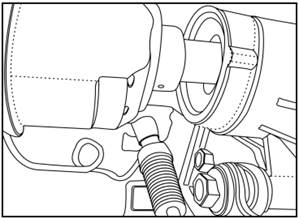

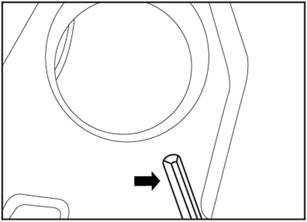

1.

Remove the end cover according to the sequence of replacing the drive bevel

gear end cover.

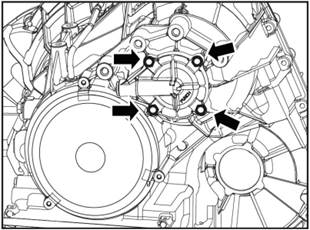

2. Remove the 6 bolts from the oil

pump and put the special tool on the oil pump shaft.

3.

Pull out the oil pump with special T-tool (480141).

4. When replacing new oil pump, it

must be confirmed that two new 0-rings are put on the new oil pump. Be careful

not to pull out the conical return spring, and make sure the larger end is

facing to the oil pump.

-

42 -

8.4

installment

1.

Install oil pump

1)

When installing the new oil pump, make sure to put two new O-rings on the new

oil pump.

▲Note:

Do not take out the conical return spring, and make sure the larger end is

facing to the oil pump.

2) Reinstall the 6 bolts, and tighten them with the

torque of I0N·m+/-IN·m.

2) Reinstall the 6 bolts, and tighten them with the

torque of I0N·m+/-IN·m.

3) Put the end cover back according

to the steps, do not replace the O-ring and end cover.

▲Note: Do not replace the O-ring

and end cover.

3.

Install the transmission

4.

Fill the transmission oil.

9. Drive Bevel Gear Shaft

Ball Bearing

9.1

Fault code instruction

Replace the drive bevel

gear shaft ball bearing if it wear out. A worn drive bevel gear shaft ball

bearing will have large noise, and the noise varies with engine speed. So if

you change from D gear to manual mode at constant speed and the noise suddenly

increases, it is very likely that the bearing is damaged. Because after

changing to manual gear, the speed remains the same but the engine speed

increases.

9.2

Special tool

|

No.

|

Tool No.

|

Tool name

|

Tool

illustration

|

|

1

|

16G0049

|

Drive bevel gear

shaft bearing plug

|

|

|

2

|

16G0050

|

Drive bevel gear

shaft bearing punch

|

|

|

3

|

16G0048

|

Drive

bevel gear shaft bearing removal tool

|

|

|

4

|

16G0047

|

Drive

bevel gear shaft big nut removal and installation sleeve

|

|

9.3 disassemble

1.

Discharge the transmission oil.

2.

Remove the transmission.

3.

Remove the drive bevel gear shaft end cover. Refer to the drive bevel gear

shaft end cover.

4. Remove the oil pump. Refer to

the oil pump.

4. Remove the oil pump. Refer to

the oil pump.

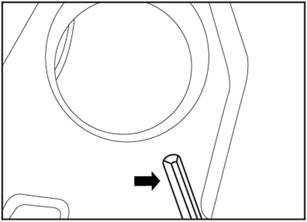

5. Remove

the drive bevel gear shaft ball bearing.

1)

Take out the conical return spring.

2)

Mark the shaft and nut.

3)

Remove the nut with the special sleeve.

4)

Remove the dust cover from the bearing with flat screwdriver.

5)

Put the protection plug on the shaft.

6) Assemble bearing removal device

(16G0048), and hook the outer ring of the bearing with its foot.

7) Tighten the middle bolt to pull out the bearing.

9.4

installment

1.

Install the drive bevel gear shaft ball bearing

1) Clean

the sealant of the drive bevel gear shaft and oil pump drive shaft lock belt,

and oil pump chamber.

2) Put the new bearing in place and

install it with a special punch (16G0050).

3) Knock

the punch into place with a rubber hammer.

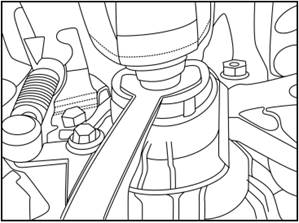

4) Tighten the nut so that the mark

on the shaft coincides with the mark on the nut. Standard coincidence degree

±5°

4) Tighten the nut so that the mark

on the shaft coincides with the mark on the nut. Standard coincidence degree

±5°

5)

Install the conical return spring.

2.

Install the drive bevel gear shaft end cover.

▲Note: Do not replace

the O-ring and end cover.

3.

Install the transmission.

4.

Fill the transmission oil.

▲Note:

The larger end of the diameter is toward the oil pump.

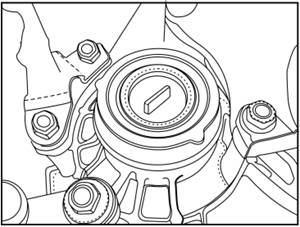

10.Driven Bevel Gear Shaft End Cover

10.1

Fault code instruction

Driven

bevel gear shaft end cover damaged or leaks oil

10.2

disassemble

1.

Remove the driven bevel gear shaft end cover.

1).

Remove the 4 countersunk screws.

2) Take down the two

O-rings and the one sealing ring on the end cover.

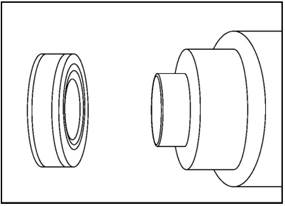

10.3

installment

1.

Install the driven bevel gear shaft end cover.

1)

Install the two O-rings and the one sealing ring on the end cover.

2)

Clear the thread glue in the 4 screw holes on the shell.

3).

Tighten the 4 screws. Tightening torque 9.5±0.95N·m.

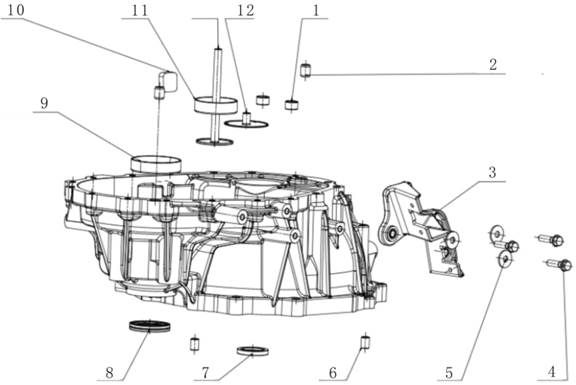

11.Oil pan

11.1

Fault code instruction

Oil

pan damaged or leaks oil

11.2

disassemble

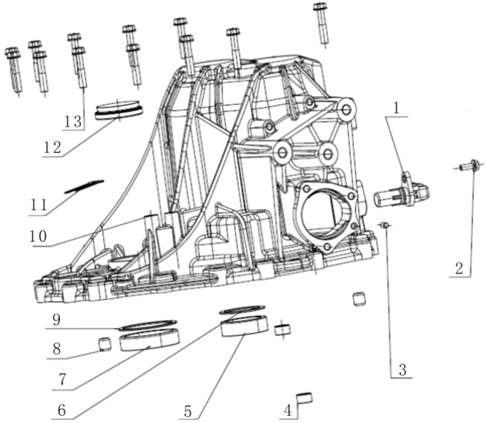

1.

Discharge the transmission oil.

2)Remove the oil pan.

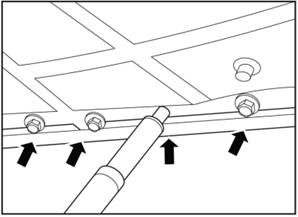

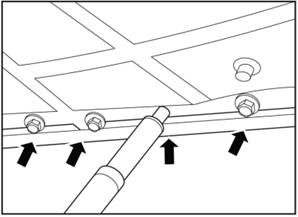

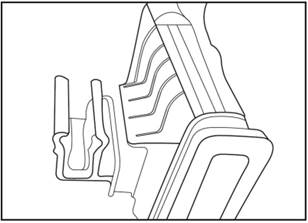

1)

Install the 13 bolts on the oil pan.

11.3

installment

1.

Install the oil pan.

1)

Install the new oil pan and gasket.

2)

Install the oil pan bolts according to the sequence as shown in the picture.

▲Note:

Use new bolt gasket. Tightening torque 9.5±1N·m.

2.

Fill the transmission oil.

12. Oil Filter

12.1

Fault code instruction

Oil

filters should be replaced at least every 60,000km or 2 years (whichever comes

first), and the period can be reduced according to the standard of each

manufacturer.

12.2

disassemble

1.

Discharge the transmission oil.

2.

Remove the oil pan. Refer to the oil pan.

3.

Remove the oil filter.

1)

Take out the oil filter slightly and abandon it.

12.3

installment

1.

Install the oil pan.

1)

Install oil filter with a new O-ring, and lubricate it with ESSO EZL799 (A).

2)

Gently press the oil filter in place.

▲Note: The hole in the middle of the oil filter is

matched with the middle bolt on the hydraulic control block.

▲Note: The hole in the middle of the oil filter is

matched with the middle bolt on the hydraulic control block.

3)

Clean the magnet and the oil pan.

2)Install oil pan.

3. Fill

the transmission oil.

13. Driving Mode Sensor

13.1

Fault code instruction

The

fault code should display the fault of the driving mode sensor, replace the

driving mode sensor.

13.2

disassemble

1.

Discharge the transmission oil.

2.

Remove the oil pan. Refer to the oil pan.

3.

Remove the oil filter. Refer to the oil filter.

4.

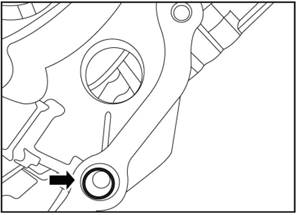

Remove the driving mode sensor.

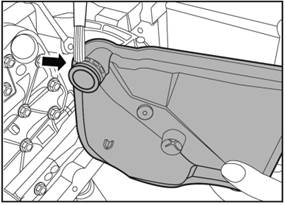

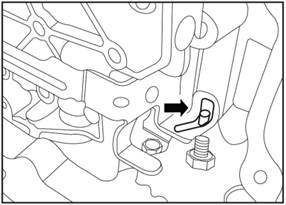

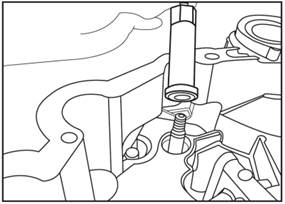

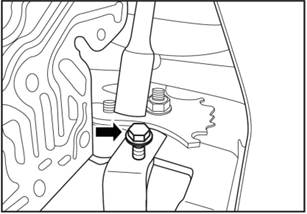

1)

Remove the 2 screws on the driving mode sensor.

2)

Carefully take down the driving mode sensor from the hydraulic control block.

▲Note: Behind the sensor is a small

pin with hydraulic pressure. The metal slider on the control block is fixed

together, pressing the sensor down to release the pin from the slider.

3) Use flat screwdriver to open the lock on the sensor

joint, and press the white lock to separate the joint.

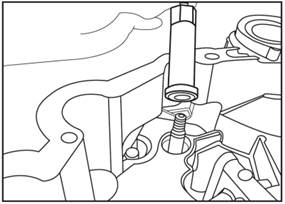

13.3

installment

1.

Install the driving mode sensor.

1)

Take a new sensor, connect the connector, and press the white lock button

inside to lock it.

2)

Put the pin behind the sensor on the metal slider and install it in place.

3)

Move the sensor to expose the bolt hole.

4)

Tighten the 2 fixing screws. Tightening torque 9.5±0.95N·m.

2.

Install the oil filer.

3)

Install the oil pan.

4. Fill

the transmission oil.

14.

Hydraulic Control Module

14.1 Fault

code instruction

If

the transmission pressure is found to be too low or the driving process

vibration or abnormal phenomenon, there are two important components can cause

this problem: oil pump and hydraulic control block. Use the fault code to

determine which one needs to be replaced. In most cases it is not completely

clear which one is the problem, just replace one by one to see whether the

problem is solved.

|

No.

|

Tool No.

|

Tool name

|

Tool

illustration

|

|

1

|

16G0046

|

Locating pin of

hydraulic control module

|

|

14.2

disassemble

1.

Discharge the transmission oil.

2. Remove the oil pan. Refer to the oil pan.

3. Remove the oil filter. Refer to the oil filter.

4. Remove the driving mode sensor. Refer to the

driving mode sensor.

5. Remove the hydraulic control module

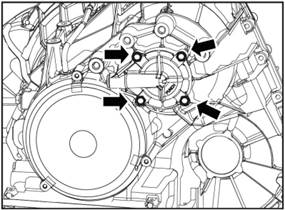

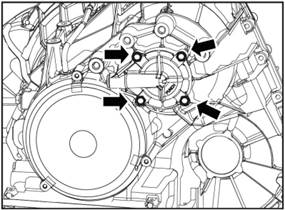

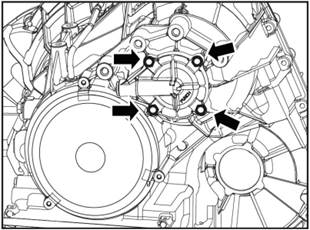

1) Remove the bolts according to

the sequence from 20 to 1 as shown in the picture.

2) Take out the hydraulic control module, and separate the

▲Note:

Use flat screwdriver can easily take down the connector.

14.3

installment

1.

Install the hydraulic control module

1) Install the hydraulic control

module in place and put a small pin behind the hydraulic control module in the

correct position.

2)

Ensure that the metal slide and the pin on the shift cam are installed rightly

3) Install the middle bolt and

tighten it by hand.

4) Install the special tool 16G0046

in the bolt hole in the upper left angle.

5) Press the wire of the drive

bevel gear speed sensor on the upper left corner of the hydraulic control

module.

6) Install all the bolts of the

hydraulic control module and tighten them in the order from 1 to 20.

6) Install all the bolts of the

hydraulic control module and tighten them in the order from 1 to 20.

Tightening

torque 11N·m.

2. Install the driving mode sensor.

3. Install the oil filter.

4) Install the oil pan.

5. Fill the transmission oil.

15. Driven Bevel Gear Speed Sensor and Bracket

15.1

Fault code instruction

Judge the fault of this component

by the fault code.

15.2

disassemble

1.

Discharge the transmission oil.

2. Remove

the oil pan. Refer to the oil pan.

3.

Remove the oil filter. Refer to the oil filter.

4.

Remove the driving mode sensor. Refer to the driving mode sensor.

5.

Remove the hydraulic control module. Refer to the hydraulic control module.

6.

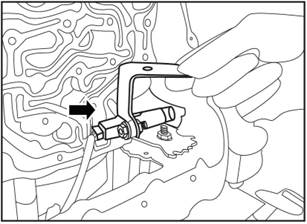

Remove the driven bevel gear speed sensor and bracket.

1).

Loosen the sensor bracket bolts.

▲Note: This bolt is disposable.

2) Take out the bracket from the

gear shifting shaft.

3) Remove the sensor and connector with needle-nosed

pliers.

4)

Loosen the bolts on the bracket and remove the speed sensor.

15.3 installment

1. Install the driven bevel gear

speed sensor and bracket.

1. Install the driven bevel gear

speed sensor and bracket.

1) Install the new

sensor and bracket, and tighten the fixing bolts.

2) Connect the wire, and clamp the bracket

to the gear shifting shaft, and install it in place.

3)

Use new bolt to fix the bracket. Tightening torque 9.5±0.95N·m.

2.

Install the hydraulic control module

3. Install the driving mode sensor.

4. Install the oil filter.

5) Install the oil pan.

6. Fill the transmission oil.

16. Drive Bevel Gear Speed Sensor

16.1

Fault code instruction

Judge

the fault of this component by the fault code.

16.2

disassemble

1.

Discharge the transmission oil.

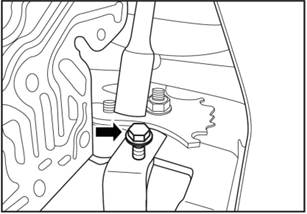

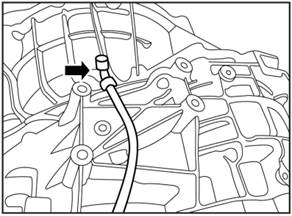

2.

Remove the drive bevel gear end cover. Refer to the drive bevel gear end cover.

3.

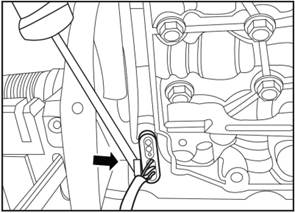

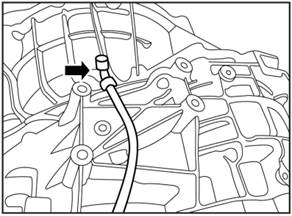

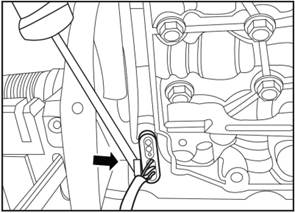

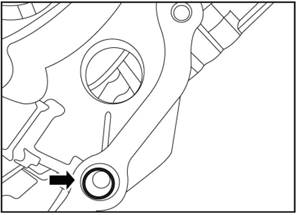

Remove the drive bevel gear speed sensor.

1)

Remove the fixing bolt, and take out the sensor.

2)

Separate the wire and take down the sensor.

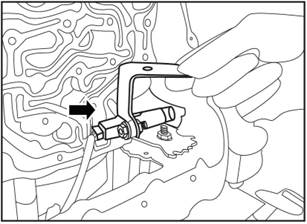

16.3

installment

1.

Intall the drive bevel gear speed sensor.

1)

Install the new sensor, and tighten the bolt. Tightening torque 8.5±2N·m.

2)

Connect the wire to the sensor.

2.

Install the drive bevel gear end cover

3. Fill

the transmission oil.

17.

Main Connector and Inner Wire Harness

17.1

Fault code instruction

Judge

the fault of this component by the fault code.

17.2

disassemble

1.

Discharge the transmission oil.

2.

Remove the oil pan. Refer to the oil pan.

3.

Remove the oil filter. Refer to the oil filter.

4.

Remove the driving mode sensor. Refer to the driving mode sensor.

5.

Remove the hydraulic control module. Refer to the hydraulic control module.

6.

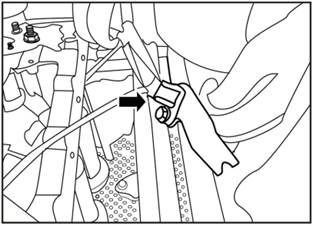

Remove the main connector and inner wire harness.

1).

Separate the two speed sensor connector.

2).

Take the wire connecting vehicle and main connector.

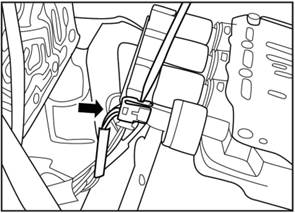

2) Take down the buckles on the

main connector, and press the main connector into the transmission.

▲Note: Driving mode sensor

connector is clamped on the housing, take down the connector first.

4)

Take the whole main connector from the transmission.

17.3

installment

1.

Installthe main connector and inner wire harness

1)

Take a new main connector, and put it into the transmission.

▲Note:

The main connector is attached to the housing through a spline, and it’s easy

to

press

upward with a 45 degree nose clamp.

2)

Install the buckle.

3) Press

the driving mode sensor connector onto the housing.

4)

Connect the speed sensor and connector.

2. Install the hydraulic control module

3. Install the driving mode sensor.

4. Install the oil filter.

5) Install the oil pan.

6. Fill the transmission oil.

18.

Breather Pipe

18.1

Special tool

|

No.

|

Tool No.

|

Tool name

|

Tool

illustration

|

|

1

|

16G0044

|

Installation

tool-breather pipe

|

|

18.2 disassemble

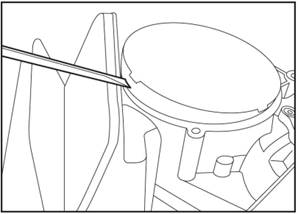

1. Remove the engine intake pipe.

1. Remove the engine intake pipe.

2. Remove the battery and bracket.

3. Remove the breather pipe.

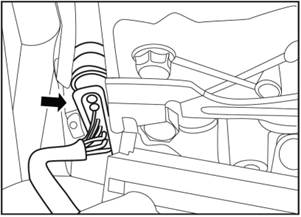

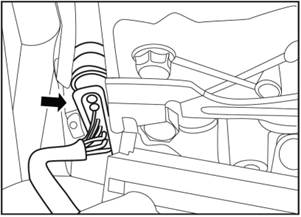

1) Remove the clips

from the top of the breather pipe and the transmission.

2) Clamp is placed at the

connection between the shell and the breather pipe, and take down the breather

pipe.

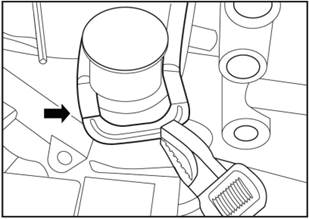

18.3 installment

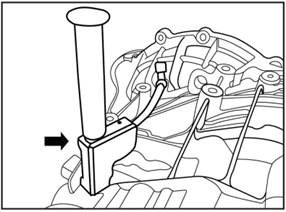

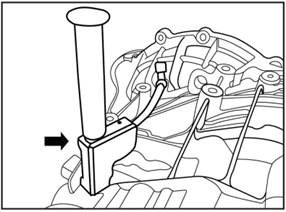

1.

Installthe breather pipe.

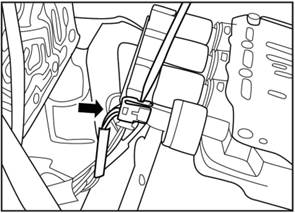

1)

Place the new breather pipe in the special tool (16G0044) and apply a little

vaseline to the aluminum tube at the bottom of the breather pipe.

2) Place the breather pipe in the

tool box on the shell and keep it parallel. Hit the tool vertically with the

rubber hammer to make the breather pipe enter into the shell.

3)

Put plastic clips 482253 on the breather pipe.

4)

Insert the pin of the plastic clasp into the hole of the metal clasp 481456.

5) Install the metal clasp firmly

on the reinforcing rib of the transmission housing.

6)

Install the breather pipe cap 483117 on the pipe, and pay attention to the

installation in place.

2.

Install the battery and bracket.

3.

Install engine intake pipe.

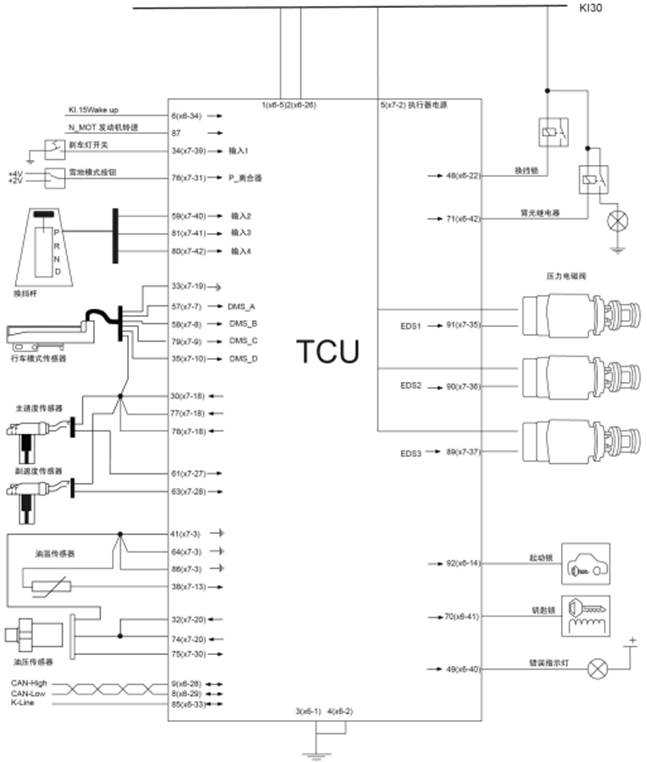

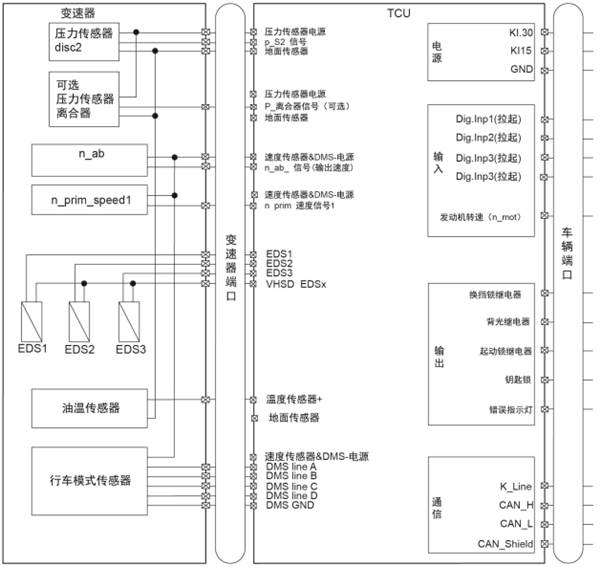

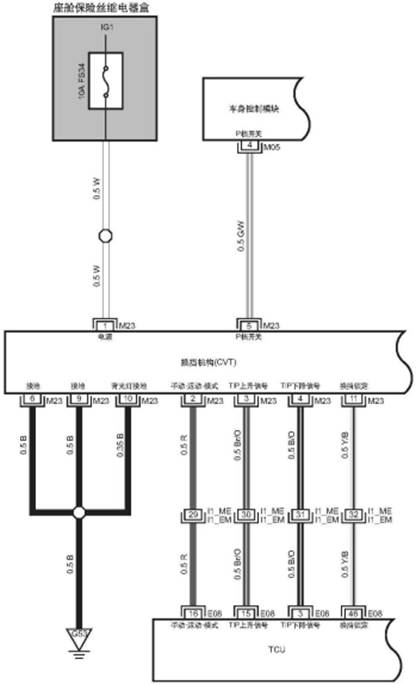

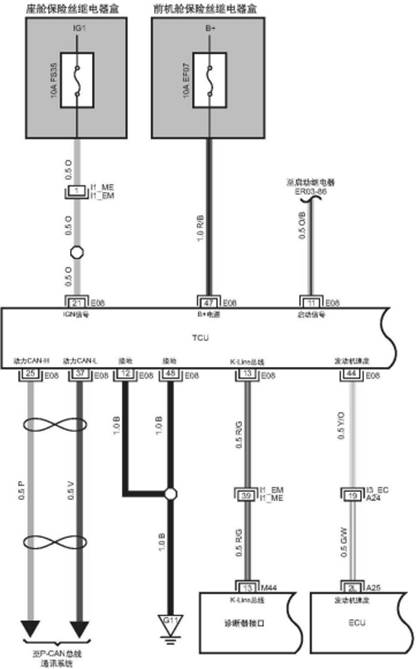

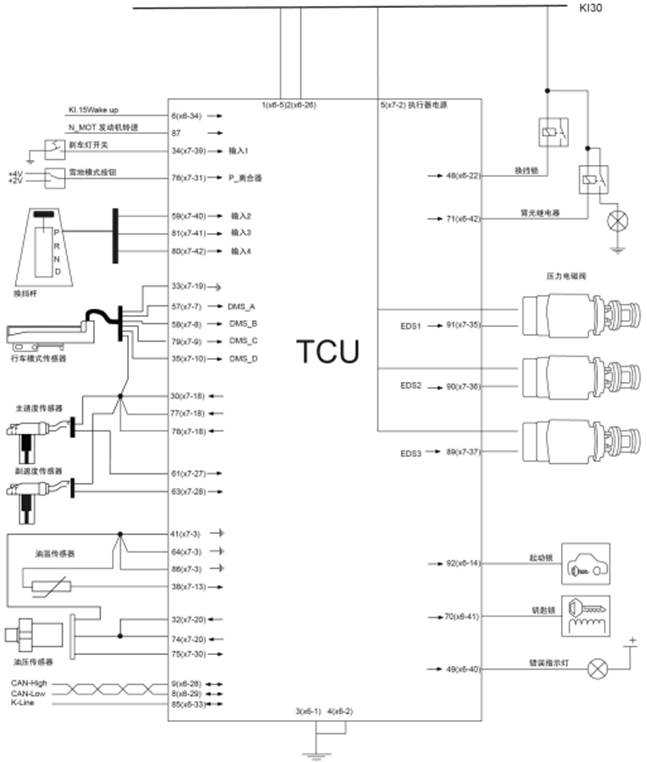

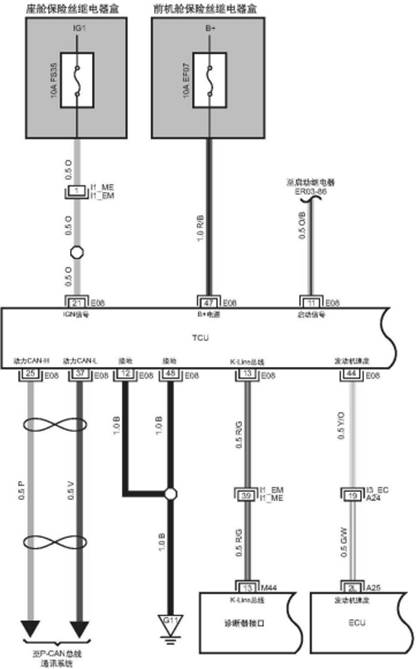

Chapter IV

Electrical Schematic Diagram

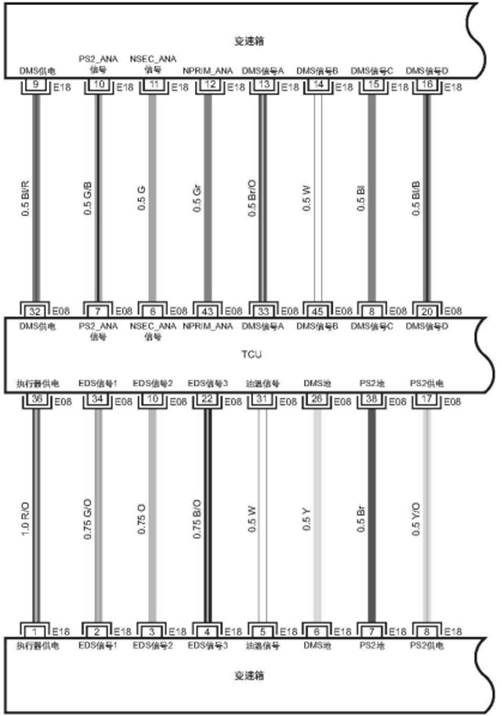

1.TCU Connector Diagram

1.1

TCU Connector

5(x7-2)

Actuator power supply

|

|

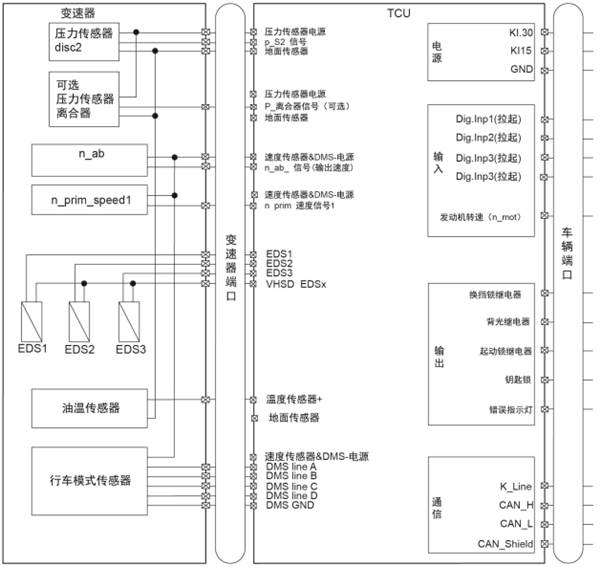

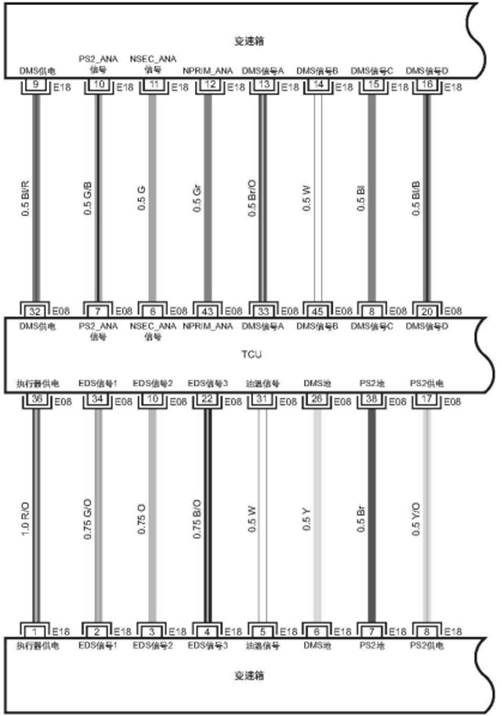

1.2 TCU and Transmission Connector

Speed

sensor&DMS-power supply

|

|

Variable

Pressure

sensor clutch

|

|

Speed

sensor&DMS-power supply

|

|

N_ab_signal

(output speed)

|

|

Speed

sensor&DMS-power supply

|

|

p_Clutch

signal (variable)

|

|

Pressure

sensor power supply

|

|

Pressure

sensor power supply

|

|

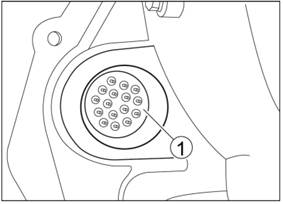

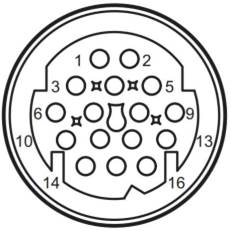

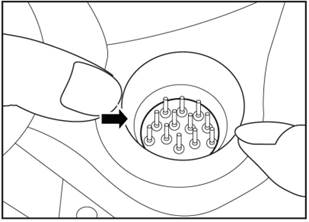

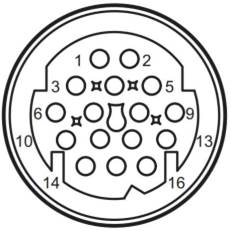

1.3Pins of

Transmission Main Connector

Connector

layout (transmission side)

Pin distribution

|

Pin

|

Signal

|

Pin

|

Signal

|

|

1

|

Supplying valve (VHS)

|

9

|

Power supply_8,4V

|

|

2

|

EDS_1

|

10

|

P_S2

|

|

3

|

EDS_2

|

11

|

n_ab

|

|

4

|

EDS_3

|

12

|

n_S1

|

|

5

|

Oil temperature

|

13

|

DMS_A

|

|

6

|

DMS_GND

|

14

|

DMS_B

|

|

7

|

Sensor GND

|

15

|

DMS_C

|

|

8

|

Power supply_5V

|

16

|

DMS_D

|

|

Signal

|

Instructions

|

|

DMS

|

Driving mode sensor or gear/restrain

sensor

|

|

EDS_1

|

Drive bevel gear

pressure regulator (solenoid valve)

|

|

EDS_2

|

Driven bevel gear pressure regulator

(solenoid valve)

|

|

EDS_3

|

Clutch pressure regulator (solenoid

valve)

|

|

P_S2

|

Driven bevel gear pressure sensor

|

|

N_ab

|

Driven bevel gear speed sensor

|

|

N_S1orN_Prim

|

Drive bevel gear speed sensor

|

TCU

pin distribution

|

VT3-signal

|

Pin

|

|

Always

close power supplyy Kl.30

|

1;2

|

|

Ignition

power supply Kl.15

|

6

|

|

Grounding Kl.31

|

3;4

|

|

VHSD1

(Actuator power supply)

|

5

|

|

Speed

and position sensor power supply (8.4V)

|

30; 77; 78

|

|

Pressure

sensor power supply (5V)

|

32;74

|

|

GND

Driving mode sensor

|

33

|

|

GND

sensor grounding

|

41; 64; 86

|

|

Transmission oil temperature

|

38

|

|

N_Prim

(drive bevel gear speed)

|

61

|

|

N_ab

(driven bevel gear speed)

|

63

|

|

N_MOT

(Engine speed signal)

|

87

|

|

DMS_A

(Driving mode sensor signal)

|

57

|

|

DMS_B

(Driving mode sensor signal)

|

58

|

|

DMS_C

(Driving mode sensor signal)

|

79

|

|

DMS_D

(Driving mode sensor signal)

|

35

|

|

Brake signal

|

34

|

|

Manual mode signal

|

59

|

|

Gear inceasing signal

|

81

|

|

Gear deceresing signal

|

80

|

|

P_S2

(Driven bevel gear pressure)

|

75

|

|

Snow mode

|

76

|

|

Gear shift lock

|

48

|

|

K-line

|

85

|

|

CAN-H

|

9

|

|

CAN-L

|

8

|

|

Start lock

|

92

|

|

EDS1

(Driven bevel gear pressure regulator)

|

91

|

|

EDS2

(Driven bevel gear pressure regulator)

|

90

|

|

EDS3

(Driven bevel gear pressure regulator)

|

89

|

|

Reversing lamp relay

|

71

|

2. Electronic Component Inspection List

2.1

Driving mode sensor

Check

the resistance between different pins, and judge if the driving mode sensor is

good.

DMS_GND

= pin-6

DMS_A

=pin-13 DMS_B =pin-14 DMS_C =pin-15 DMS_D =pin-16

DMS_Supply = pin-9

2.2

Corresponding Resistance Value of Each Pin

|

|

DMS_Supply

|

DMS_A

|

DMS_B

|

DMS_C

|

DMS_D

|

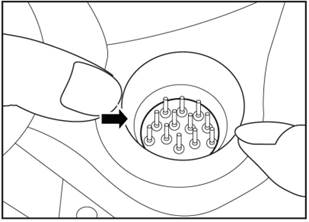

|