Cautions for electrical technicians using medical electrics

Forbidden operation

Warning:

● There is strong magnetic components on this vehicle

● If technician use medical electrics,e.g electronic pacemakers, which couldn’t be operated in the vehicle ,otherwise,the function of electrics may be effected by strong magnetic components.

Cautions for normal charge

Warning:

● If technician use the medical electrics like pacemakers, cardiovascular, in addition to the top, the machine only could be used after the function of machine checked and confirmed before normally operation.

● In the normal charging operation, Medical electrics may be affected by electromagnetic wave. When Technicians use the medical electrics like pacemakers, cardiovascular, in addition to the top etc, it is not allowed to enter into crew capsule (including luggage).

Cautions for communication equipment

● If technicians use the medical electrics like pacemakers, cardiovascular, in addition to the top etc, please keep enough distance with the communication equipment.

● Remote intelligent terminal of electromagnetic waves may affect the function of the medical electrics like pacemakers, cardiovascular, in addition to the top etc.

● If technicians use the medical electrics like pacemakers, cardiovascular, in addition to the top etc, remote intelligent terminal of electromagnetic waves may affect the function of the medical electrics. It is needed to let the manufacturer of the medial electrics confirm that the possible affection to medical electric equipment when using remote intelligent terminal.

Keypoint checking before maintenance

High pressure system can be run automatically, it is need to confirm that remote air conditioning and recharged regularly are not set before maintenance.

Cautions:

● If set remote air-conditioner or charged regularly, even though the switch is closed, high pressure system can be run automatically.

Cautions for "safety airbag"and"safety belt preloaded"of auxiliary constraint system

The combination use of "safety airbag"and"safety belt preloaded"of auxiliary constraint system and front seat belt could decrease the damage to driver and passengers when collision. The auxiliary constraint system include seat belt, airbag for driver, airbag for co-driver. The detailed information for auxiliary constraint system could refers to the sections of “airbag system” and “seat belt”

Warning:

To avoid unexpected accident, we need to obey the following:

● To avoid the auxiliary constraint system invalid, all the maintenance only could be operated by JAC authorized distributors because the risk of injury to people will be increased after invalid.

● Non-standard auxiliary constraint system of maintenance including non-standard disassembly and installation, may result in auxiliary constraint system accident triggered, causing personal injury accidents. About remove the airbag module method, please see "airbag system" section.

● In addition to the maintenance instructions in the manual operation, do not use electrical test equipment to test any circuit of auxiliary constraint system. Auxiliary constraint system of connectors and wiring harness use yellow or orange color.

Cautions when use electrical tools (pneumatic or electric)and hammer

● when electric switch in the "ON" block, near the airbag diagnostic sensors or other sensor, do not use power tools or hammer to operate sensor parts area. Severe vibration may activate the sensor, some airbags, causing serious damage.

● When using power tools or hammer, put the keys in the "LOCK" block, unplug the 12 v lead-acid battery cathode, waiting at least 1 minute, then for checking and maintenance.

Cautions for removing 12V battery

Turn the key to “on”,then to “lock” before remove 12v battery

Tip:

● Even if the key in the "LOCK" and the 12 v battery charging function may start automatically.

● After turn the key to "ON" --> "LOCK", 12 v battery automatic charging will not start.

Cautions for Electrical parking(EPB) maintenance

● As a result of the dust in rear brake has an effect to human body, please use clear dust collector to clean before maintenance ,it is prohibited to use air gun blow out.

● When electronic parking work, state of electronic parking lights lit on combination instrument.

● When the electric parking in the event of a failure, the warning lights lit on the instrument (yellow).

Caution:

● When the electronic parking is in fault state, if pull or press the EPB switch, failure indicator will light (yellow).

● When the electronic parking happens fault and unable to release or could not connected to the 12 v battery, and must release the electronic parking at this time, please use external release way to release the parking brake, see "external release"

● After change parking ECU assembly or parking ECU bracket, the parking ECU assembly is needed to be calibrated as zero, see "zero in parking ECU assembly learning".

Special tools

The actual tool shape may be different from illustration shown.

|

Tool |

Diagram |

Instruction |

|

Diagnostic instrument X-431 |

|

EPB system fault diagnosis |

|

Tool |

Diagram |

Instruction |

|

Power tool |

|

Install and remove bolts and nuts |

This car is equipped with electronic parking brake (EPB) system. EPB recognition is from EPB switch signal, controlled by the ECU's assembly, which controls the brake caliper assembly clamping and release the parking brake. EPB switch layout is in the intermediate position of the assistant instrument board, which is convenient for the pilot operation.

Position of component parts

|

|

||||||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||||||

|

A Instrument panel |

B Downside of instrument panel |

C Rear suspension |

|

Serial No |

Name |

Function |

|

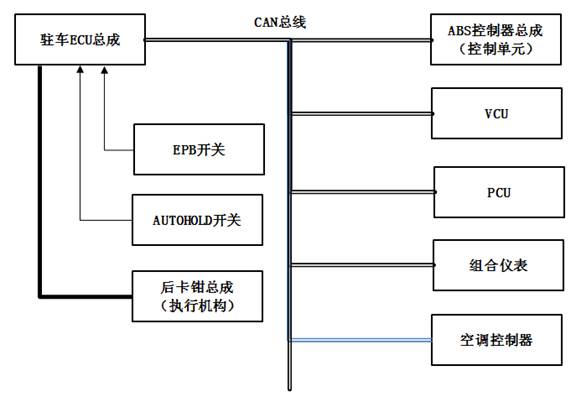

1 |

Motor controller(PCU) |

Send actual torque motor and motor speed signal Through CAN bus to the EPB system, which is used to start auxiliary functions for EPB. |

|

2 |

ABS controller assembly ABS |

Send the wheel speed signal, two rear wheel speed pulse signal, the speed signal through CAN line to the EPB system, which is used for EPB system to determine the vehicle state. |

|

3 |

Combination instrument |

Send left front door status and main driving belt status signal to EPB system through CAN line, which is used for EPB system to judge whether the driver is ready to start the vehicle. Receiving EPB system status,lit on or off parking light Receiving EPB system fault status, lit on or off EPB fault light. |

|

4 |

VCU |

Send motor fault information, the accelerator pedal signal, brake pedal signal, shift signal, the key state signals to EPB system through CAN line. Receiving EPB state signal, fault code and perform the corresponding control strategy. |

|

5 |

Air-conditioner controller |

Send environment temperature signal to EPB system through CAN line, which is used for EPB system estimateing the temperature of the brake disc. |

|

6 |

EPB switch |

Pull out switch、parking; press down switch, release parking. When parking, parking status light is on ; when releasing parking, parking status light is off. |

|

7 |

AUTOHOLD switch |

Control EPB system entry and exit the automatic parking mode. Press down the switch, the EPB system enter into automatic parking mode, switch state light is on; Press the switch again, EPB system exit automatic parking mode, switch state lights is off. |

|

8 |

Parking ECU assembly |

According to EPB switch state, the vehicle information from the CAN line could judge the driver's intentions, control rear caliper assembly clamping and released and realize the EPB system functions. |

|

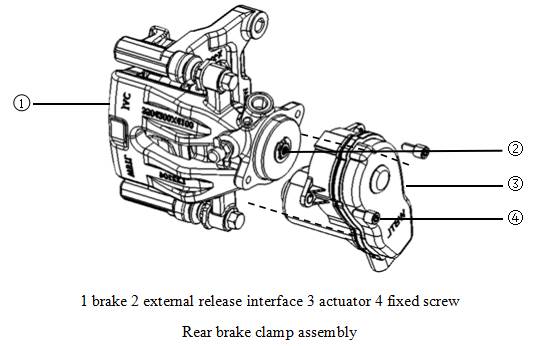

9 |

Rear brake plier assembly |

Including two parts of brake and actuators, according to the parking ECU assembly instruction to clamp and release to realize each function of EPB system. |

|

|

|

1Brake |

2 outer releasing connection |

3 executive mechanical |

|

4 fixing bolt |

5 Rear brake plier assembly |

|

System description

When electronic parking brake works, lights on combination instrument and EPB switch will be on.

When parking brake is released, lights on combination instrument and EPB switch will be off

When the driver operate EPB switch, EPB switch will transfer the signal to the parking ECU assembly, which drives the executive mechanical of rear caliper assembly in parking ECU assembly, executive mechanical push rear caliper brake to realize parking and release.

System principle

|

Parts |

Signal description |

|

Motor controller(PCU) |

Send the following signal through CAN line to parking ECU assembly: Motor actual torque signal Motor actual rotating speed signal |

|

ABS controller assembly |

Send the following signal through CAN line to parking ECU assembly: wheel speed signal Rear wheel speed pulse signal Speed signal |

|

Combination instrument |

Send the following signal through CAN line to parking ECU assembly: left front door status signal main driving belt status signal Receiving the following signal through CAN line from parking ECU assembly: EPB system status signal EPB system fault signal |

|

Vehicle controller |

Send the following signal through CAN line to parking ECU assembly: Motor fault information Accelerator pedal signal Brake pedal switch signal Shift signal Key state signals Receiving the following signal through CAN line from parking ECU assembly: EPB status signal EPB fault information |

|

Air-conditioner control system |

Send the following signal through CAN line to parking ECU assembly: Temperature signal of outside. |

EPB

Manual clamping

When vehicle stops, pull out the EPB switch, brake caliper assembly began to apply the parking brake force.

When the parking brake force reached set value, the parking status light is lit.

When the vehicle under the electricity, the parking status light is extinguished, the state in the EPB switch will be off 2 minutes later.

Tips:

Parking brake force will maintain.

Pull out two times

When vehicle stops, pull out the EPB switch, brake caliper assembly began to apply the parking brake force.

When the parking brake force reached set value, the parking status light is lit.

Pull out the EPB switch again; EPB system will increase clamping force.

Tips:

When you feel there is not enough parking power in the car, you can do this, such as when the vehicle in the larger ramp.

When the vehicle is off power, parking status light is off and the status light on EPB switch will be off 2 minutes later.

Tips:

Parking brake force will maintain.

Manual releasing

When the power switch is placed in the "ON" block, press down the brake pedal; and press the EPB switch at the same time, then the rear brake caliper assembly release parking.

Tips:

It couldn’t release parking if only pressing down EPB switch.

When electrical parking brake release fully, EPB status indicator light will be off.

Caution:

When the power switch is placed in the "LOCK” or “ACC” block, it couldn’t release parking through above operation.

Automatic release

When start driving and comply with the following conditions, vehicle will automatically release the parking brake.

1) Vehicle at “READY” status

2) Driver’s safty belt fasten

3) Door closed in driver’s side.

4) Shift is in “D” or “R”

5) Driver pedal down the accelerating pedal.

6) Vehicle with enough power to assure no slip slope.

When Electrical parking brake releases fully, EPB status indicator light will be off.

Electrical off parking

If the driver don’t do the parking operation before leaving vehicle, if the power switch is on “LOCK” block, EPB system will automatically parking.

Automatic parking

Place the key on the block of “ON”, press down “AUTOHOLD” switch, automatically parking function will be open. When the vehicle meets the following condition, automatically parking will happen.

1) Brake from the speed >4km/h to zero.

2) Vehicle completely stops.

3) The shift is on “N” shift.

When the road slope≤5%, EPB system will automatically parking after vehicle completely stopped for 2s.

When the road slope>5%, EPB system will automatically parking once vehicle completely stopped.

Tips:

This function is often used for urban traffic jam or ramp traffic condition, which has an impact on energy consumption and travel distance. it is not recommended to use in the general situation.

Braking in driving

In the process of driving, continuously pull the EPB switch, EPB system will provide brake force to make the vehicle deceleration, while brake lights up at the same time. When the vehicle is perfectly stopped, EPB system will exert maximum braking force and complete the parking.

In the EPB braking process, the EPB system will not lock the rear wheels and cause vehicle tail out.

If loosen the EPB switch before vehicle stopping, EPB system will be released in full, the brake lights at the same time, and vehicle driving back to normal.

Tips:

With the method of pulled EPB switch to stop the vehicle, when the vehicle stops, the EPB system will exert maximum braking force, the vehicle impact will happen, which is not a fault.

Caution:

When driving, pull out EPB switch, the brake force of EPB system producing is less than the braking force of hydraulic system providing, and the braking distance will be longer.

This function should be used under the case of vehicle braking system invalid, frequent use can reduce life of rear brake.

Caution:

When ABS fault light lit up, EPB system will no longer be anti-lock function, if pulled EPB switch at this time, EPB will impose a fixed braking force.

When ABS fault light lit up, if pulled EPB switch on wet road, it will happen tail out. Please use the operation pull up and down, pull up and down again to let the vehicle stop. ABS故障灯点亮时,如

When ABS fault light lit up, EPS system will not complete parking after vehicle stopped, it need release EPB switch and lull up again to complete parking.

When ABS fault light lit up, please don’t stop the vehicle on the slope road, otherwise, it may not parking .

Service release

When need to replace the rear brake caliper assembly, friction slices or brake disc, release parking could be through EPB switch.

① When vehicle in flat road with slope ≤10%;

② Put EPB in the releasing status and step down brake pedal.

③ Press EPB switch for 10s and loose the EPB switch and press again immediately, the operational mechnical will bring the piton to the maximum position, when you could take out the rear brake caliper friction slices or brake disc easily.

Tips:

After finishing parts replacement or repair, pulled EPB switch for the first time, parking time will be long, which is a normal phenomenon.

External release

When power supply system of low voltage for vehicle is unusual, or parking ECU assembly and actuator are damaged, which might not release the parking brake through EPB switch, at this time, releasing the parking brake could use a special tool.

① Remove the fixing bolts of executive mechanical and brake, take out the executive mechanical slightly.

② Rotate screw in clockwise with special tool, release parking brake.

Caution:

External release will damage seal ring between the actuator and brake, so unless confirming the brake caliper assembly damage, do not use external release.

After external release, suggest replace rear brake caliper assembly.

Condition s for indicator light and fault light

When the electric switch turn from “ON” to “LOCK”or from the “LOCK” switch to “ON”, indicator light and fault light will light up to complete self-inspection.

|

Condition(status) |

EPB status indicator (red) |

EPB fault warning light (yellow) |

EPB switch indicator light |

AUTOHOLD switch indicator light |

Tips statement in instrument |

|

Parking |

ON |

OFF |

ON |

OFF |

|

|

With power, press down AUTOHOLD switch |

OFF |

OFF |

OFF |

ON |

|

|

Not step down brake pedal, press down EPB switch |

ON |

OFF |

OFF |

OFF |

|

|

Not fasten safety belt tightly, do automatically releasing function |

ON |

OFF |

OFF |

OFF |

Please fasten tightly the safety belt |

|

When parking brake system has fault(when parking) |

OFF |

ON |

OFF |

OFF |

Please go to 4S shop for maintenance |

|

When parking brake system has fault(when parking is releasing) |

ON |

ON |

OFF |

OFF |

Please go to 4S shop for maintenance |

|

When EPB system has fault and EPB switch is operating, while the system couldn’t work. |

ON |

ON |

ON |

OFF |

Please go to 4S shop for maintenance |

When EPB system has fault, fault warning light will be on in the instrument.

When EPB system has fault, part of EPB function will be limited. When the system couldn’t parking, pull out or press down EPB switch, the indicator in the switch will flash and the yellow fault indicator light in the instrument will be on.

Tips:

When electrical parking couldn’t be released through switch, please do “outer releasing” manually.

|

Fault code |

Fault name |

Fault grade |

Phenomenon of vehicle fault |

|

C110017 |

System voltage is too high |

1 |

System voltage >16.5V, the system closed, unable to parking and release, all function is limited. |

|

C110060 |

Actuator operating voltage is too low. |

1 |

Parking and releasing function of fault actuator is in valid actuators clamps with maximum clamping force |

|

C110016 |

System voltage is too low |

1 |

System voltage <8.5 V, the system closed, unable to parking and release, all function is limited. |

|

C110116 |

Electrical line has fault |

4 |

Take CAN signal as standard, system stability decreases. |

|

C11A418 |

Actuator has fault |

1 |

Parking and releasing function of fault actuator is in valid actuators clamps with maximum clamping force |

|

C11A477 |

Actuator has fault-low voltage |

1 |

Parking and releasing function of fault actuator is in valid actuators clamps with maximum clamping force |

|

C11A07C |

Left actuator has fault- operating overtime |

1 |

Parking and releasing function of left actuator is invalid Right actuators clamps with maximum clamping force |

|

C11A37C |

Right actuator has fault- operating overtime |

1 |

Parking and releasing function of right actuator is invalid Left actuators clamps with maximum clamping force |

|

C11A013 |

Left actuator has fault- open circuit |

1 |

Parking and releasing function of left actuator is invalid Right actuators clamps with maximum clamping force

|

|

C11A313 |

Right actuator has fault- open circuit |

1 |

Parking and releasing function of right actuator is invalid Left actuators clamps with maximum clamping force |

|

C11A011 |

Left actuator has fault- control line failure |

1 |

Parking and releasing function of left actuator is invalid Right actuators clamps with maximum clamping force |

|

C11A311 |

Right actuator has fault- control line failure |

1 |

Parking and releasing function of right actuator is invalid Left actuators clamps with maximum clamping force |

|

C11A07E |

Left actuator has fault-effective pipe failure |

1 |

Parking and releasing function of left actuator is invalid Right actuators clamps with maximum clamping force |

|

C11A37E |

Right actuator has fault-effective pipe failure |

1 |

Parking and releasing function of right actuator is invalid Left actuators clamps with maximum clamping force |

|

C11A070 |

Left actuator has fault- mechanical damaged |

1 |

Parking and releasing function of left actuator is invalid Right actuators clamps with maximum clamping force |

|

C11A370 |

Right actuator has fault-mechanical damaged |

1 |

Parking and releasing function of right actuator is invalid Left actuators clamps with maximum clamping force |

|

C11A015 |

Left actuator has fault- short circuit |

1 |

Parking and releasing function of left actuator is invalid Right actuators clamps with maximum clamping force |

|

C11A315 |

Right actuator has fault-short circuit |

1 |

Parking and releasing function of right actuator is invalid Left actuators clamps with maximum clamping force |

|

C11A07D |

Left actuator has fault-relay |

1 |

Parking and releasing function of left actuator is invalid Right actuators clamps with maximum clamping force |

|

C11A37D |

Right actuator has fault-relay |

1 |

Parking and releasing function of right actuator is invalid Left actuators clamps with maximum clamping force |

|

C11A063 |

Left actuator has fault- transistor |

1 |

Parking and releasing function of left actuator is invalid Right actuators clamps with maximum clamping force |

|

C11A363 |

Right actuator has fault- transistor |

1 |

Parking and releasing function of right actuator is invalid Left actuators clamps with maximum clamping force |

|

C11A054 |

Left actuator has fault- Calibration error |

1 |

Parking and releasing function of left actuator is invalid Right actuators clamps with maximum clamping force |

|

C11A354 |

Right actuator has fault- Calibration error |

1 |

Parking and releasing function of right actuator is invalid Left actuators clamps with maximum clamping force |

|

C113800 |

Switch failure |

2 |

Manual function is invalid, automatic parking and release function open automatically. |

|

C113861 |

Switch failure- unstable status |

2 |

Manual function is invalid, automatic parking and release function open automatically. |

|

C11352A |

Switch failure-pulling unsmoothly |

2 |

Manual function is invalid, automatic parking and release function open automatically. |

|

C11362A |

Switch failure-releasing unsmoothly |

2 |

Manual function is invalid, automatic parking and release function open automatically. |

|

C110860 |

Switch failure-electrical failure |

2 |

Manual function is invalid, automatic parking and release function open automatically. |

|

C110862 |

Switch failure-status not the same |

2 |

Manual function is invalid, automatic parking and release function open automatically. |

|

C116045 |

Controller fault- stack |

4 |

System function limited |

|

C116040 |

Controller fault- D/a conversion |

4 |

System function limited |

|

C116042 |

Controller hardware fault-EEPROM |

4 |

System function limited |

|

C116055 |

Controller fault- equipped wrong |

4 |

System function limited |

|

C116086 |

Controller fault-data invalid |

4 |

System function limited |

|

C116054 |

Controller fault- No calibration |

6 |

System function could be realized but the performance appears decreasing. |

|

C11604C |

Controller hardware fault- Advocate complementary communication |

6 |

System function could be realized but the stability becomes decreasing. |

|

C116004 |

Controller fault- Auxiliary chips |

6 |

System function could be realized but the stability becomes decreasing. |

|

C116046 |

Controller hardware fault- Primary storage |

4 |

System function limited |

|

C116044 |

Controller hardware fault- random storage |

4 |

System function limited |

|

C11607C |

Controller fault- Auxiliary input/output control chip |

4 |

System function could be realized but the stability becomes decreasing. |

|

C111329 |

Acceleration sensor signal invalid |

4 |

When parking, perform maximum clamping force, it could not judge the vehicle dynamic or static in the condition of ABS fault. |

|

C111396 |

Acceleration sensor Self-checking failure |

4 |

perform maximum clamping force when parking. |

|

U007388 |

CAN line bus off CAN |

3 |

System goes into the degraded mode. In the IGN OFF state, parking can be achieved by static testing function, in IGN on state, releasing can be achieved through press the switch for long time. |

|

U000188 |

Node of CAN line loss |

3 |

System goes into the degraded mode. In the IGN OFF state, parking can be achieved by static testing function, in IGN on state, releasing can be achieved through press the switch for long time. |

|

U010087 |

Node of PCU loss |

4 |

Automatic releasing function invalid. |

|

U010187 |

Node of VCU loss |

4 |

Automatic releasing function invalid. |

|

U012987 |

Node of ABS_ESC loss |

4 |

Dynamic braking function invalid、parking function when power off is invalid. |

|

U014087 |

Node of ICM loss |

4 |

Automatic releasing function invalid、automatic and leasing function is in valid. |

|

U012687 |

Node of AC loss |

4 |

Clamping function under high temperature downgrade |

|

U040186 |

Node of PCU with invalid signal |

4 |

Automatic releasing function invalid. |

|

U040286 |

Node of VCU with invalid signal |

4 |

Automatic releasing function invalid. |

|

U048186 |

Node of ABS_ESC with invalid signal |

4 |

Dynamic braking function invalid、parking function when power off is invalid. |

|

U042286 |

Node of ICM with invalid signal |

4 |

Automatic releasing function invalid、automatic and leasing function is in valid. |

|

U042886 |

Node of AC with invalid signal |

4 |

Clamping function under high temperature downgrade |

|

C11D114 |

EPB status light-Open circuit or short circuit to ground |

4 |

EPB status light is always off. |

|

C11D112 |

EPB status light- short circuit to height |

4 |

EPB status light is always on. |

|

C116154 |

Calibration is not finished after off line |

6 |

Slope accuracy is reduced, slide may happen |

When multiple fault codes appear at the same time, rule out according to the fault grade step by step.

Tip:

Fault grade data is less, the grade is higher.

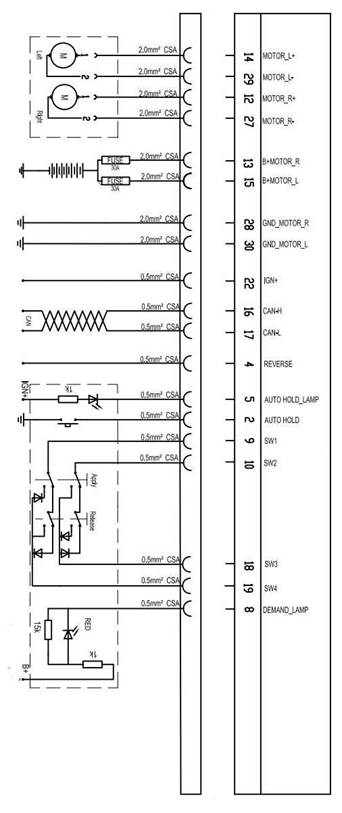

Stitch definition of connectors

Stitch definition of connectors of parking ECU assembly

|

Stich no |

Definition |

Stich no |

Definition |

|

1 |

N/A |

16 |

CAN high / CAN-H |

|

2 |

Automatic parking switch signal/Autohold |

17 |

Can low / CAN-L |

|

3 |

N/A |

18 |

EPB switch signal 3/SW3 |

|

4 |

N/A |

19 |

EPB switch signal 43/SW4 |

|

5 |

Automatic parking switch indictator controlling signal/Autohold lamp |

20 |

N/A |

|

6 |

N/A |

21 |

N/A |

|

7 |

N/A |

22 |

Power on switch signal/IGN+ |

|

8 |

Indicator controlling signal in parking status /Demand lamp |

23 |

N/A |

|

9 |

EPB switch signal 1/SW1 |

24 |

N/A |

|

10 |

EPB switch signal 2/SW2 |

25 |

N/A |

|

11 |

N/A |

26 |

N/A |

|

12 |

Right actuator control positive/Motor_R+ |

27 |

Right actuator control negative/Motor_R- |

|

13 |

Right actuator power positive/B+Motor_R |

28 |

Right actuator power ground/GND Motor R |

|

14 |

Left actuator control positive/Motor_L+ |

29 |

Left actuator control negative/Motor_L- |

|

15 |

Left actuator power positive/B+Motor L |

30 |

Left actuator power ground/GND Motor L |

Stitch definition of connectors of executive mechanical

Connectors of left and right actuator are the same, stitch definition is the same.

|

|

Stich no |

Definition |

Stich no |

Definition |

|

1 |

Motor power+ |

2 |

Motor power- |

Diagnosis and maintenance process

Fault diagnosis process details

1 Collect customer information

Before check, carefully ask customer concerns or driving vehicles together with the customer which is very important for solving the problem.

2 Check symptoms

According to the information collected through interviewing with the customer ,reappear information of customer specified symptoms. Check whether the symptoms caused by the failure mode.

Caution:

When symptoms are caused by normal operation, please fully inspect each related parts and let customers understand the symptoms are normal.

3 Diagnose whether there is fault code with diagnostic instrument

Yes>>record and delete fault code, turn to next step

No>> turn to “Normal symptom and analysis”

4 Fault confirmed again

Appears fault again and diagnose whether there is fault code with diagnostic instrument.

Yes>> turn to “fault code, electrical line fault diagnosis”

No>> check harness and connector based on discussion face to face, please see “ground and loop”

5 Maintenance or replace fault parts

Maintenance or replace fault parts, connect the connectors and harnesses again and delete fault code with diagnostic instrument.

6 Do the fault operation again to check whether there is a still fault symptom.

Yes>> back to step 3

Diagnosis working list

In general, customers have their own judgment standard to a problem. Therefore, careful enough to ask to understand customer's concern is very important. Preparing interview list makes diagnostic information systematic. Sometimes, many conditions occur at the same time resulting in failure.

Interview list sample

|

Interview list |

|||||

|

Customer name |

Gender |

Plate No |

|

Original registered date |

|

|

Model |

|

VIN |

|

||

|

Production date |

|

Motor power |

|

Mileage |

km |

|

Fault conditions |

Fault type |

□Unable to parking □Unable to release

□Abnormal noise |

|||

|

Detailed symptom |

|

||||

|

Detailed abnormal noise |

|

||||

|

Shift |

□R □N □D |

||||

|

Safety belt |

□With □Without |

||||

|

Brake pedal status |

□NON Step □Step |

||||

|

Parking brake status |

□release status □parking status □releasing □parking □Continuous |

||||

|

Vehicle status |

□Key LOCK □Key ACC □Key ON □READY |

||||

|

Vehicle moving status |

□Start in shift D □Drive in shift D

□Parking in shift D |

||||

|

Road conditions |

□Steep downhill □Slow down □Flat Road |

||||

|

Passengers |

□5 □4 □3 □2 □1 |

||||

|

Vehicle loading conditions |

|

||||

|

Outer releasing history |

|

||||

|

Interview list |

|||||

|

Customer name |

Gender |

Plate No |

|

Original registered date |

|

|

Model |

|

VIN |

|

||

|

Production date |

|

Motor power |

|

Mileage |

km |

|

Check result |

Check result |

|

|||

|

12V battery status |

□Normal □Abnormal( ) □Pending |

||||

|

Connectors status |

□Normal □Abnormal( ) □Pending |

||||

|

EPB brake status |

□Normal □Abnormal( ) □Pending |

||||

|

Friction plate status |

□Normal □Abnormal( ) □Pending |

||||

|

EPB switch status |

□Normal □Abnormal( ) □Pending |

||||

|

Other status |

|

||||

Zero position learning of Parking ECU assembly

Description

Caution:

When remove、change parking ECU assembly or bracket, zero position learning of parking ECU assembly is needed to be done.

Working process

Caution:

Diagnostic instrument must be used to carry out the offline learning.

1. Vehicle preparation

① Put the vehicle in the flat road.

② Put the power-on switch in “OFF”shift.

2. Check whether the installation state of parts of EPB system is normal, if it is normal, please enter into the next step. If not, please repair or replace defective parts.

3. Put the power-on switch in “ON” block, check whether there is fault with echocardiography, if yes, check and repair. Please see "Fault code, circuit fault diagnosis”. If not, enter into the next step.

4. Select "EPB," "off line zero calibration", "start". Complete zero learning based on diagnostic instrument.

Caution:

Forbidden to operate EPB switch in the process of zero positioning learning.

5. System fault diagnostic

① Pull up EPB switch, do parking brake.

② Step down the brake pedal, press down EPB switch and release parking brake.

6. Diagnose whether there is fault code with diagnostic instrument, if yes, check and repair. Please see "Fault code, circuit fault diagnosis”. If not, enter into the next step.

7. Delete previous fault

① Put the power-on switch in “OFF” block, then put it in”ON”block after 10s.

Caution:

Take action according to step ①

② Clear historical fault, if successful, zero learning is over. If not, check the fault codes and carry out maintenance.

Fault code, circuit fault diagnosis

Parking ECU assembly fault C116045、C116040、C116042、C116055、C116086、C116054、C11604C、C116004、C116046、C116044、C11607C、C111329、C111396

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

C116045 |

Controller fault- stack |

Parking ECU assembly control abnormally. |

Harness or connectors Parking ECU assembly

|

|

C116040 |

Controller fault- D/a conversion |

Parking ECU assembly control abnormally. |

|

|

C116042 |

Controller hardware fault-EEPROM |

Parking ECU assembly control abnormally. |

|

|

C116055 |

Controller fault- equipped wrong |

Parking ECU assembly control abnormally. |

|

|

C116086 |

Controller fault-data invalid |

Parking ECU assembly control abnormally. |

|

|

C116054 |

Controller fault- No calibration |

Parking ECU assembly control abnormally. |

|

|

C11604C |

Controller hardware fault- Advocate complementary communication |

Parking ECU assembly control abnormally. |

|

|

C116004 |

Controller fault- Auxiliary chips |

Parking ECU assembly control abnormally. |

|

|

C116046 |

Controller hardware fault- Primary storage |

Parking ECU assembly control abnormally. |

|

|

C116044 |

Controller hardware fault- random storage |

Parking ECU assembly control abnormally. |

|

|

C11607C |

Controller fault- Auxiliary input/output control chip |

Parking ECU assembly control abnormally. |

|

|

C111329 |

Acceleration sensor signal invalid |

Parking ECU assembly control abnormally. |

|

|

C111396 |

Acceleration sensor Self-checking failure |

Parking ECU assembly control abnormally. |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of ECU assembly is damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Perform self-diagnosis

① Delete fault code

② Put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

4 Replace parking ECU assembly, please see “Remove and installation”

5 Execute zero position learning of parking ECU assembly; do self-diagnosis to check whether fault code exists.

Yes >> check、maintenance the harness connected with parking ECU assembly. Please see “Electric sub-manual - grounding and loop”

No >> finish diagnosis

6 Take action on self-diagnosis and delete old fault code after finishing diagnosis.

Fault of parking executive mechanical driving circuit

C11A011、C11A311、C11A07E、C11A37E、C11A07D、C11A37D、C11A063、C11A363

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

C11A011 |

Left actuator has fault- control circuit failure |

Parking ECU checks out the fault of parking executive mechanical driving circuit |

Harness or connectors Parking ECU assembly |

|

C11A311 |

Right actuator has fault- control circuit failure |

Parking ECU checks out the fault of parking executive mechanical driving circuit |

|

|

C11A07E |

Left actuator has fault-effective pipe failure |

Parking ECU checks out the fault of parking executive mechanical driving circuit |

|

|

C11A37E |

Right actuator has fault-effective pipe failure |

Parking ECU checks out the fault of parking executive mechanical driving circuit |

|

|

C11A07D |

Left actuator has fault-relay |

Parking ECU checks out the fault of parking executive mechanical driving circuit |

|

|

C11A37D |

Right actuator has fault-relay |

Parking ECU checks out the fault of parking executive mechanical driving circuit |

|

|

C11A063 |

Left actuator has fault- transistor |

Parking ECU checks out the fault of parking executive mechanical driving circuit |

|

|

C11A363 |

Right actuator has fault- transistor |

Parking ECU checks out the fault of parking executive mechanical driving circuit |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of ECU assembly is damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Perform self-diagnosis

① Delete fault code

② Put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

4 Replace parking ECU assembly, please see “Remove and installation”

5 Execute zero position learning of parking ECU assembly; do self-diagnosis to check whether fault code exists.

Yes >> check、maintenance the harness connected with parking ECU assembly. Please see “Electric sub-manual - grounding and loop”

No >> finish diagnosis

6 Take action on self-diagnosis and delete old fault code after finishing diagnosis.

Fault of parking actuator C11A418、C11A477、C11A07C、C11A37C、C11A013、C11A313、C11A070、C11A370、C11A015、C11A315、C11A054、C11A354

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

C11A418 |

Actuator has fault |

Acutator couldn’t execute the order of parking ECU assembly. |

Harness or connectors Left and right rear brake caliper assembly Parking ECU assembly |

|

C11A477 |

Actuator has fault-low voltage |

Parking ECU assembly checks out that the voltage at both end of actuator is less than 9V. |

Harness or connectors Left and right rear brake caliper assembly Parking ECU assembly |

|

C11A07C |

Left actuator operates overtime |

Left actuator parking overtime. |

Harness or connectors Left rear brake caliper assembly Parking ECU assembly |

|

C11A37C |

Right actuator operates overtime |

Right actuator parking overtime. |

Harness or connectors Right rear brake caliper assembly Parking ECU assembly |

|

C11A013 |

Left actuator is in open circuit. |

Parking ECU assembly checks out left actuators with open circuit. |

Harness or connectors Left rear brake caliper assembly Parking ECU assembly |

|

C11A313 |

Right actuator is in open circuit. |

Parking ECU assembly checks out right actuators with open circuit. |

Harness or connectors Right rear brake caliper assembly Parking ECU assembly |

|

C11A070 |

Left actuator mechanical is damaged. |

Parking ECU assembly checks out left actuators with damaged circuit. |

Harness or connectors Left rear brake caliper assembly Parking ECU assembly |

|

C11A370 |

Right actuator mechanical is damaged. |

Parking ECU assembly checks out Right actuators with damaged circuit. |

Harness or connectors Right rear brake caliper assembly Parking ECU assembly |

|

C11A015 |

Left actuator is short circuit |

Parking ECU assembly checks out left actuators with short circuit. |

Harness or connectors Left rear brake caliper assembly Parking ECU assembly |

|

C11A315 |

Right actuator is short circuit |

Parking ECU assembly checks out right actuators with open circuit. |

Harness or connectors Right rear brake caliper assembly Parking ECU assembly |

|

C11A054 |

Left actuator with Calibration error |

Parking ECU assembly checks out left actuators without calibration for delivery out of factory. |

Harness or connectors Left rear brake caliper assembly Parking ECU assembly |

|

C11A354 |

Right actuator with Calibration error |

Parking ECU assembly checks out left actuators without calibration for delivery out of factory. |

Harness or connectors Right rear brake caliper assembly Parking ECU assembly |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of parking mechanical is damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Check whether the assembly of friction plate is abnormal or excessive wear.

Yes>> assembly again or replace. Next step.

No>> Next step

4Perform self-diagnosis

① Delete fault code

② Put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

5 check、maintenance the harness connected executive mechanical with parking ECU assembly. Please see “Electric sub-manual - grounding and loop”

Yes>>replace the fault rear brake caliper assembly. Please see “brake system-rear brake caliper assembly-remove and installation”. Next step.

No >> finish diagnosis

6 do self-diagnosis to check whether fault code exists.

Yes>>replace parking ECU assembly. Please see “remove and installation”

No >> finish diagnosis

7 Take action on self-diagnosis and delete old fault code after finishing diagnosis.

Switch fault C113800、C113861、C11352A、C11362A、C110860、C110862 EPB

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

C113800 |

Switch failure |

Parking ECU assembly checks out switch with fault. |

Harness or connectors EPB switch Parking ECU assembly |

|

C113861 |

Switch failure- unstable status |

EPB switch status change |

|

|

C11352A |

Switch failure-pulling unsmoothly |

EPB switch output the signal of pulling up more than 20s |

|

|

C11362A |

Switch failure-releasing unsmoothly |

EPB switch output the signal of releasing more than 20s |

|

|

C110860 |

Switch failure-electrical failure |

Parking ECU assembly don’t check out signal or couldn’t recognize signal. |

|

|

C110862 |

Switch failure-status not the same |

Advocate complementary chip of parking ECU assembly checks out the EPB switch state is not the same. |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of EPB assembly are damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Perform self-diagnosis

① Delete fault code

② Put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

4 Change EPB switch ,do self-diagnosis to check whether fault code exists.

Yes>> next step

No >> finish diagnosis

5 Replace parking ECU assembly, please see “ remove and installation”

6 Start zero position learning of parking ECU assembly,do self-diagnosis to check whether fault code exists.

Yes>> check、maintenance the harness connected EPB switch with parking ECU assembly. Please see “Electric sub-manual - grounding and loop”

No >> finish diagnosis

7 Take action on self-diagnosis and delete old fault code after finishing diagnosis.

System electrical supplying fault U100016、U100017

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

U100016 |

System voltage is too low |

Supply voltage of parking ECU assembly<8.5V |

Harness or connectors Parking ECU assembly 12V battery |

|

U100017 |

System voltage is too high |

Supply voltage of parking ECU assembly>16.5V |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of parking ECU assembly are damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Put power on switch on shift “ON”, check whether the voltage of 12V battery is abnormal.Please see “Electric sub-manual - grounding and loop”.

Yes>>replace 12V battery. Please see “Electric sub-manual - grounding and loop”. Next step.

No>> Next step

4 Perform self-diagnosis

① Delete fault code

② Put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

5 Check grounding circuit of parking ECU assembly

① Put the power on switch in the shift “LOCK”.

② Pull out he connectors of parking ECU assembly, check whether the corresponding stitch at harness end of stitch28 and stitch30 are unobstructed.

Yes>> next step

No >> circuit fault of parking ECU, maintenance or replacement. Please see“Electric sub-manual - grounding and loop”.

6 Check electrical supplying circuit of parking ECU assembly

check whether the voltage between corresponding stitch at harness end of stitch13 and stitch15 and ground are normal.

Yes>> next step

No >> circuit fault of parking ECU, maintenance or replacement. Please see“Electric sub-manual - grounding and loop”.

Caution:

perform self-diagnosis and clear fault codes after grounding or power supply circuit breakdown maintenance,and confirm whether the fault has been exempted. If fault unwinding, please continue to conduct diagnosis.

7 Replace parking ECU assembly, please see “Remove and installation”. Do the zero position learning of parking ECU assembly.

8 Take action on self-diagnosis and delete old fault code after finishing diagnosis.

Hard line signal fault of power-on switch C110116

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

C110116 |

Electrical switch circuit has fault |

Parking ECU assembly couldn’t receive signal of power-on or there is different between hardline signal and CAN signal. |

Harness or connectors Parking ECU assembly |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of parking ECU assembly are damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Perform self-diagnosis

① Delete fault code

② put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

4 Check grounding circuit of parking ECU assembly

① Put the key in the shift “LOCK”.

② Pull out he connectors of parking ECU assembly, check whether the corresponding stitch at harness end of stitch28 and stitch30 are unobstructed.

Yes>> next step

No >> grounding fault, maintenance or replacement. Please see“Electric sub-manual - grounding and loop”.

5 Check electrical supplying circuit of parking ECU assembly

① check whether the voltage between corresponding stitch at harness end of stitch22 and ground is zero.

② Put the power on switch in shift “ON” to check whether the voltage between corresponding stitch at harness end of stitch22 and ground is normal.

Yes>> next step

No >> power on switch signal fault, maintenance or replacement. Please see“Electric sub-manual - grounding and loop”.

Caution:

Perform self-diagnosis and clear fault codes after grounding or power supply circuit breakdown maintenance,and confirm whether the fault has been exempted. If fault unwinding, please continue to conduct diagnosis.

6 Replace parking ECU assembly, please see “Remove and installation”. Do the zero position learning of parking ECU assembly.

7 Take action on self-diagnosis and delete old fault code after finishing diagnosis.

Communication fault U010187、U040286

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

U010187 |

Node of VCU loss |

Parking ECU assembly couldn’t receive VCU signal through CAN . |

Vehicle controller CAN communication system Parking ECU assembly |

|

U040286 |

Node of VCU with one invalid signal VCU |

One of the VCU signal which received by parking ECU assembly is in valid. |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of EPB controller assembly are damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Perform self-diagnosis

① Delete fault code

② Put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

4 Check whether VCU has fault.Please see“Electric sub-manual - grounding and loop”.

Yes>>check and repair VCU. Please see“Electric sub-manual - grounding and loop”.

No>> next step

5 Check CAN communication sub-line of EPB system is normal.Please see“Electric sub-manual - CAN communication system”.

Yes>>Replace parking ECU assembly, please see “Remove and installation”. Do the zero position learning of parking ECU assembly.

No>> repair or replace fault parts. Please see“Electric sub-manual - CAN communication system”.

6 Take action on self-diagnosis and delete old fault code after finishing diagnosis.

Communication fault with PCU U010087、U040186

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

U010087 |

Node of PCU loss |

Parking ECU assembly couldn’t receive PCU signal through CAN |

Motor controller Harness or connectors Parking ECU assembly |

|

U040186 |

Node of PCU with one invalid signal |

One of the PCU signal which received by parking ECU assembly is in valid. |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of EPB controller assembly are damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Perform self-diagnosis

① Delete fault code

② Put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

4 Check whether PCU has fault.Please see“Electric sub-manual - driving system of electrical vehicle”.

Yes>>check and repair PCU. Please see“Electric sub-manual - driving system of electrical vehicle”.

No >>next step

5 Check CAN communication sub-line of EPB system is normal.Please see“Electric sub-manual - CAN communication system”.

Yes>>Replace parking ECU assembly, please see “Remove and installation”. Do the zero position learning of parking ECU assembly.

No>> repair or replace fault parts. Please see“Electric sub-manual - CAN communication system”.

6 Take action on self-diagnosis and delete old fault code after finishing diagnosis.

Communication fault with ABS U012987、U048186

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

U012987 |

Node of ABS loss |

Parking ECU assembly couldn’t receive ABS signal through CAN . |

ABS controller Harness or connectors Parking ECU assembly |

|

U048186 |

Node of ABS with one invalid signal |

One of the ABS signal which received by parking ECU assembly is in valid. |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of EPB controller assembly are damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Perform self-diagnosis

① Delete fault code

② Put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

4 Check whether ABS has fault.Please see“Electric sub-manual - brake control system”.

Yes>>check and repair ABS.Please see“Electric sub-manual - brake control system”.

No >>next step

5 Check CAN communication sub-line of EPB system is normal.Please see“Electric sub-manual - CAN communication system”.

Yes>>Replace parking ECU assembly, please see “Remove and installation”. Do the zero position learning of parking ECU assembly.

No>> repair or replace fault parts. Please see“Electric sub-manual - CAN communication system”.

6 Take action on self-diagnosis and delete old fault code after finishing diagnosis.

Communication fault U014087、U042286

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

U014087 |

Node of ICM loss |

Parking ECU assembly couldn’t receive ABS signal through CAN . |

Combination instrument Harness or connectors Parking ECU assembly |

|

U042286 |

Node of ABS with one invalid signal |

One of the ABS signal which received by parking ECU assembly is in valid. |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of EPB controller assembly are damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Perform self-diagnosis

① Delete fault code

② Put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

4 Check whether there is fault in ICM. Please see“Electric sub-manual - combination instrument”.

Yes>> Check and repair ICM. Please see“Electric sub-manual - combination instrument”.

No>> next step

5 Check CAN communication sub-line of EPB system is normal.Please see“Electric sub-manual - CAN communication system”.

Yes>>Replace parking ECU assembly, please see “Remove and installation”. Do the zero position learning of parking ECU assembly.

No>> repair or replace fault parts. Please see“Electric sub-manual - CAN communication system”.

6 Take action on self-diagnosis and delete old fault code after finishing diagnosis.

Communication fault with AC controller U0112687、U042886

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

U012687 |

Node of AC controller loss |

Parking ECU assembly couldn’t receive AC controller signal through CAN . |

AC controller Harness or connectors Parking ECU assembly |

|

U042886 |

Node of AC controller with one invalid signal |

One of the AC controller signal which received by parking ECU assembly is in valid. |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of EPB controller assembly are damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Perform self-diagnosis

① Delete fault code

② Put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

4 Check whether AC controller has fault.Please see“Electric sub-manual - AC controller”.

Yes>>check and repair.Please see“Electric sub-manual - AC controller”.

No >>next step

5 Check CAN communication sub-line of EPB system is normal.Please see“Electric sub-manual - CAN communication system”.

Yes>>Replace parking ECU assembly, please see “Remove and installation”. Do the zero position learning of parking ECU assembly.

No>> repair or replace fault parts. Please see“Electric sub-manual - CAN communication system”.

6 Take action on self-diagnosis and delete old fault code after finishing diagnosis.

CAN communication fault U007388、U000188

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

U007388 |

CAN communication fault |

Failure of input and out put of EPB system |

Harness and connectors of communication Connecting harness and connectors of parking ECU |

|

U000188 |

CAN communication fault |

All communicaiton nodes are overtime. |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of EPB controller assembly are damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Perform self-diagnosis

① Delete fault code

② Put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

4 Check whether CAN communication system has fault.Please see“Electric sub-manual - CAN communication system”.

Yes>>check and repair.Please see“Electric sub-manual - CAN communication system”.

No >>next step

5 check and repair connecting harness of parking ECU assembly. Please see“Electric sub-manual - grounding and loop”.

6 Take action on self-diagnosis and delete old fault code after finishing diagnosis.

Zero positioning unlearning of parking ECU assembly

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

C116154 |

Zero positioning unlearning of parking ECU assembly. |

Zero positioning unlearning of parking ECU assembly. |

Parking ECU assembly |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of EPB controller assembly are damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Perform self-diagnosis

① Delete fault code

② Put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

4 Do the zero position learning of parking ECU assembly.

Fault of EPB switch status C11D12、C11D14 EPB

|

Fault code |

Fault name |

Checking conditions |

Possible reason |

|

C11D12 |

EPB switch status light- short circuit to power |

EPB switch status light is always on. |

Harness or connectors EPB switch Parking ECU assembly |

|

C11D14 |

EPB status switch light-Open circuit or short circuit to ground |

EPB status switch light is always off. |

1 Preparation work

If carried out the other fault diagnosis before, please put the key in the "LOCK" block, check again after waiting for at least 10 s.

2 Check whether pins and wiring harness connector of EPB controller assembly are damaged or loosen.

Yes>> repair or replace. Next step.

No>> Next step

3 Perform self-diagnosis

① Delete fault code

② Put the key on "LOCK" block, waiting for more than 10 s.

③ Put the key on "ON" block.

④ Pull up and press down EPB switch separately once time.

⑤ Check whether fault code exists.

Yes>> next step

No >> finish diagnosis

4 Change EPB switch, do self diagnosis process to check whether there still have fault code.

Yes>> next step

No >> finish diagnosis

5 Replace parking ECU assembly, please see “Remove and installation”.

6 Do the zero position learning of parking ECU assembly.do self diagnosis process to check whether there still have fault code.

Yes>> check、repair the harness connecting EPB switch and parking ECU assembly. Please see “Electric sub-manual - grounding and loop”.

No >> finish diagnosis

7 Take action on self-diagnosis and delete old fault code after finishing diagnosis.

Press down EPB switch, parking couldn’t be released

1 Carry out self-diagnosis, check whether self-diagnosis result has fault code.

Yes >>check and maintenance of fault.Next step.

No>> Turn to 3

2 Check symptoms

Check whether parking could be released when pressing down EPB switch.

Yes>> diagnosis finish

No>> Next step

3 check the brake light switch and connecting harness on the brake pedal. Please see “Chassis sub-manual- brake system” and “Electric sub-manual - grounding and loop”

Yes>> repair or replace fault parts, turn to 2.

No>> Next step

4 Harness check

Check whether the positive and negative of harness of rear brake caliper assembly and parking ECU assembly is opposite. Please see “Electric sub-manual - grounding and loop”

Yes>> repair or replace harness.

NO >>replace parking ECU assembly; do zero position learning and delete old fault code after finishing diagnosis.

Pulling up EPB switch, vehicle couldn’t be parking

1 Carry out self-diagnosis, check whether self-diagnosis result has fault code.

Yes >>check and maintenance of fault.Next step.

No>> Turn to 3

2 Check symptoms

Check whether parking could be done when pulling up EPB switch.

Yes>> diagnosis finish

No>> Next step

3 Harness check

Check whether the positive and negative of harness of rear brake caliper assembly and parking ECU assembly is opposite. Please see “Electric sub-manual - grounding and loop”

Yes>> repair or replace harness.

NO >>replace parking ECU assembly; do zero position learning and delete old fault code after finishing diagnosis.

No way to enter into automatic parking model

1 Carry out self-diagnosis, check whether self-diagnosis result has fault code.

Yes >>Fault code、circuit fault diagnosis.Next step.

No>> Turn to 3

2 Check symptoms

Check whether it couldenter into automatic parking model.

Yes>> diagnosis finish

No>> Next step

3 check whether the light for safty belt untightening or door unlock is on.

Yes >> check and repair according to signal track. Please see “electrical sub-manual-combination instrument”

No>> Next step

3 Replace AUTOHOLD switch, check whether it could enter and exit the automatic parking model.

Yes>> diagnosis finish

No>>check and repair connecting harness for AUTOHOLD switch and parking ECU assembly.

4 Check symptoms

Check whether it could enter and exit the automatic parking model.

Yes>> diagnosis finish

No>>replace parking ECU assembly; do zero position learning and delete old fault code after finishing diagnosis.

No way to exit automatic parking model

1 Carry out self-diagnosis, check whether self-diagnosis result has fault code.

Yes >>Fault code、circuit fault diagnosis.Next step.

No>> Turn to 3

2 Check symptoms

Check whether it could enter into or exit automatic parking model.

Yes>> diagnosis finish

No>> Next step

3 Replace AUTOHOLD switch, check whether it could enter and exit the automatic parking model.

Yes>> diagnosis finish

No>>check and repair connecting harness for AUTOHOLD switch and parking ECU assembly.

4 Check symptoms

Check whether it could enter and exit the automatic parking model.

Yes>> diagnosis finish

No>>replace parking ECU assembly; do zero position learning and delete old fault code after finishing diagnosis.

Without start auxiliary function

1 Carry out self-diagnosis, check whether self-diagnosis result has fault code.

Yes >>Fault code、circuit fault diagnosis.Next step.

No>> Turn to 3

2 Check symptoms

Check whether it has start auxiliary function.

Yes>> diagnosis finish

No>> Next step

3 check whether the light for safty belt untightening or door unlock is on.

Yes >> check and repair according to signal track. Please see “electrical sub-manual-combination instrument”

No>> Next step

4 Check symptoms

Check whether it could enter and exit the automatic parking model.

Yes>> diagnosis finish

No>>replace parking ECU assembly; do zero position learning and delete old fault code after finishing diagnosis.

Vehicles slope in the parking ramp

1 Carry out self-diagnosis, check whether self-diagnosis result has fault code.

Yes >>Fault code、circuit fault diagnosis.Next step.

No>> Turn to 3

2 Check symptoms

Check whether the function for anti-slope is normal.

Yes>> diagnosis finish

No>> Next step

3 Check whether the friction plate of rear brake caliper is over worn or equippeddnotwell. Please see “Chassis submanual- brake system”

Yes>>replace or equipped friction plate again.

No>> Next step

4 Check symptoms

Check whether the function for anti-slope is normal.

Yes>> diagnosis finish

No>>replace parking ECU assembly; do zero position learning and delete old fault code after finishing diagnosis.

Driving up EPB switch, rear wheel lockup

1 Carry out self-diagnosis, check whether self-diagnosis result has fault code.

Yes >>Fault code、circuit fault diagnosis.Next step.

No>> Turn to 3

2 Check symptoms

Check whether the fault is deleted.

Yes>> diagnosis finish

No>> Next step

3 Pull out the connectors in the left rear brake caliper; pull up EPB switch and checkwhether right rear brake caliper assembly clamp tightenly.

Yes>>replace parking ECU assembly; do zero position learning and delete old fault code after finishing diagnosis.

No>> Next step

4 Adujust connectors of left and right rear brake caliper assembly and fix thenagain.

Explosion diagram

|

1Parking ECU assembly |

2 Parking ECU bracket |

Remove

1 Put power-on switches on “OFF”block, start next operation.

2 Remove rear part assembly of vice instrument board.

|

3 Pull out connectors of parking ECU assembly

|

|

|

4 Remove two fixing nuts of parking ECU assembly and its bracket, take out parking ECU assembly. ● Tightening torque: 9~11N·m

|

|

|

5 Remove two fixing bolts of parking ECU bracket, take out parking ECU bracket. ● Tightening torque: 20~25N·m

|

|

Installation

Install in the opposite order of remove.